Cummins Oil Pressure: Troubleshooting Guide

Cummins oil pressure varies depending on the engine model and operating conditions. Proper oil pressure is crucial for an engine’s performance and longevity.

It is recommended to check the specific oil pressure specifications provided by Cummins for your engine model. Low or high oil pressure can indicate potential issues that should be addressed by a qualified technician. Maintaining the correct oil pressure is essential for optimal engine health and should be prioritized.

Credit: www.harborfreight.com

Common Causes Of Low Oil Pressure

Low oil pressure in a Cummins engine can be caused by various factors. Understanding the potential causes is crucial for diagnosing and resolving the issue. This section discusses some common reasons for low oil pressure.

Degraded Oil

One possible cause of low oil pressure is degraded oil. Over time, engine oil can become contaminated with impurities, lose viscosity, or develop sludge. This compromised oil fails to provide the necessary lubrication and protection, resulting in low oil pressure.

Regular oil changes and using the recommended oil type are essential for maintaining proper oil pressure. Failure to adhere to the manufacturer’s guidelines can lead to accelerated oil degradation and subsequent low oil pressure issues.

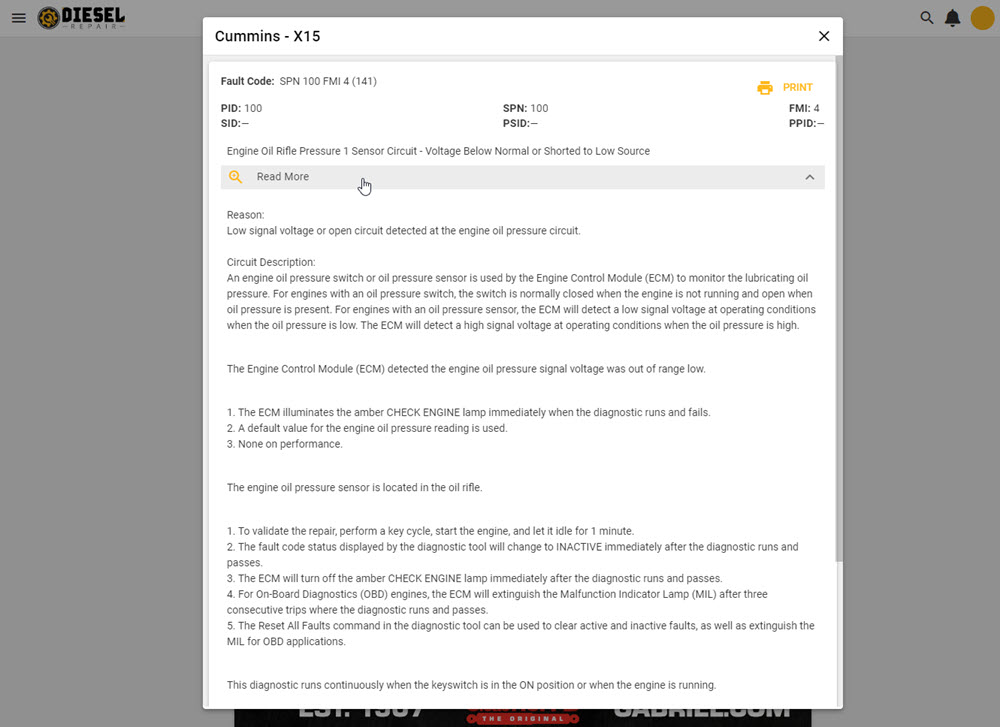

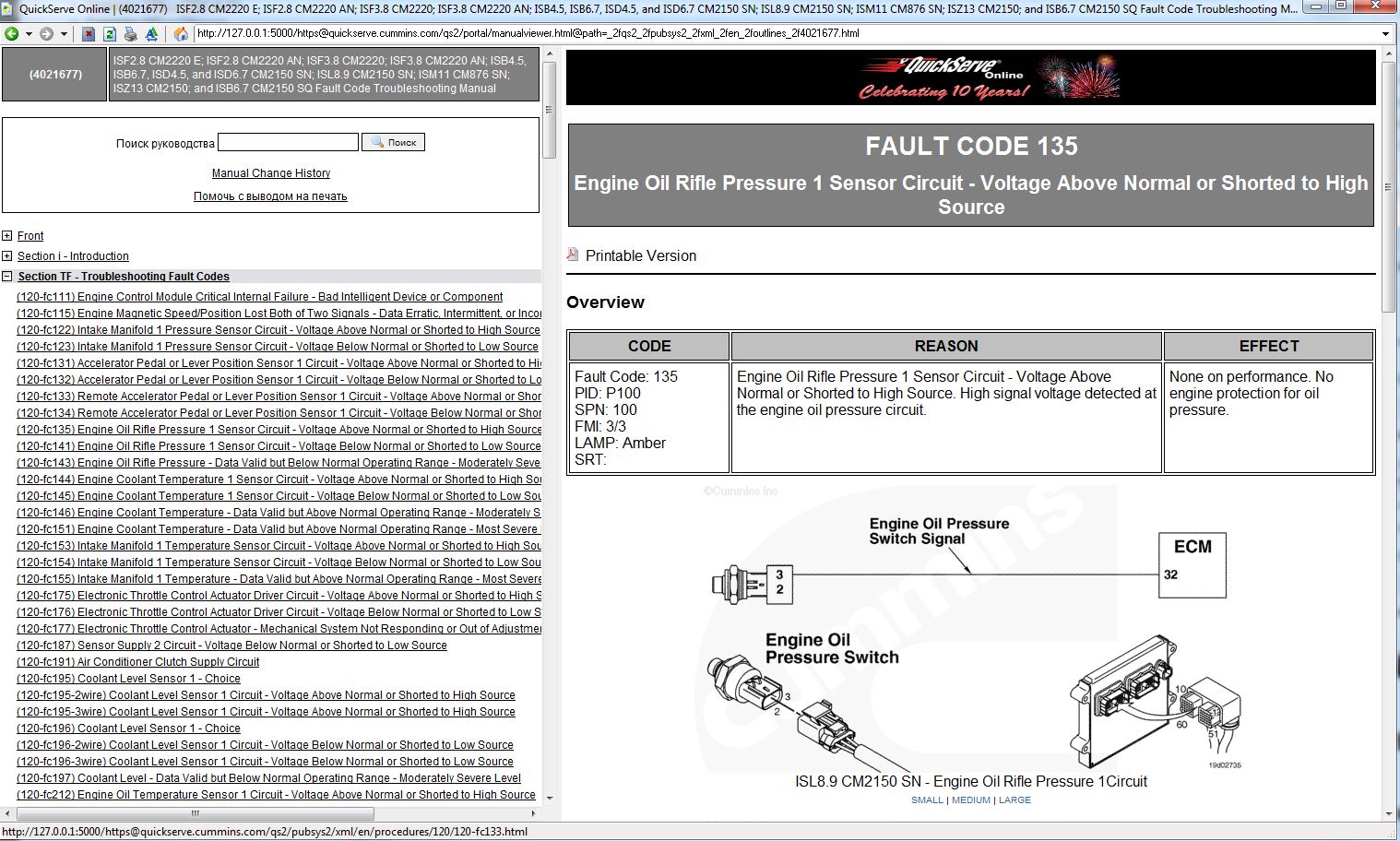

Faulty Oil Pressure Sensor

Another common culprit behind low oil pressure is a faulty oil pressure sensor. This sensor is responsible for monitoring the oil pressure and relaying information to the engine control module. If the sensor malfunctions or provides inaccurate readings, it can lead to false low oil pressure warnings.

Replacing the faulty oil pressure sensor is the most effective solution in such cases. However, it is recommended to consult a qualified mechanic to diagnose the issue accurately and avoid unnecessary costs.

In conclusion, addressing the common causes of low oil pressure, such as degraded oil and faulty oil pressure sensors, is crucial to maintain the performance and longevity of a Cummins engine. Regular maintenance, including oil changes, and prompt detection of sensor issues can help ensure optimal oil pressure levels and avoid potential engine damage.

Credit: www.hcss.com

Troubleshooting Steps For Cummins Oil Pressure Issues

Having issues with the oil pressure in your Cummins engine? Don’t worry, we’ve got you covered! In this section, we’ll discuss some troubleshooting steps that can help you identify and resolve oil pressure problems in your Cummins engine.

Check Oil Level

The first step in troubleshooting oil pressure issues is to check the oil level in your Cummins engine. Low oil level can lead to low oil pressure, causing potential damage to your engine. Here’s how you can check the oil level:

- Start your engine and let it idle for a few minutes to warm up the oil.

- Park your vehicle on a level surface and make sure it is turned off.

- Locate the oil dipstick, usually near the front of the engine.

- Remove the dipstick, wipe it clean with a cloth, and reinsert it fully.

- Take out the dipstick again and check the oil level. It should be between the ‘Min’ and ‘Max’ marks on the dipstick.

- If the oil level is low, add the recommended type and amount of oil to bring it up to the proper level.

Inspect Oil Filter

The oil filter plays a crucial role in keeping your engine clean and maintaining proper oil pressure. A clogged or damaged oil filter can result in low oil pressure. Follow these steps to inspect the oil filter:

- Locate the oil filter, usually mounted on the engine block.

- Using an appropriate wrench, carefully remove the oil filter.

- Inspect the filter for any signs of damage or excessive dirt buildup.

- If the filter looks damaged or clogged, replace it with a new one.

- Make sure to lubricate the gasket on the new oil filter with a small amount of oil before installing it.

- Hand-tighten the new oil filter until it is snug, then give it an additional half turn using the wrench.

Test Oil Pressure Sensor

The oil pressure sensor is responsible for measuring and relaying the oil pressure data to your vehicle’s dashboard. A faulty oil pressure sensor can result in inaccurate readings or no oil pressure reading at all. Here’s how you can test the oil pressure sensor:

- Locate the oil pressure sensor, typically located near the oil filter.

- Disconnect the electrical connector from the sensor.

- Using a multimeter, set it to measure resistance (ohms).

- Connect the multimeter leads to the terminals of the oil pressure sensor.

- Compare the resistance reading with the specifications provided by the manufacturer. If the reading is not within the specified range, the sensor may be faulty and needs to be replaced.

By following these simple troubleshooting steps, you can identify and resolve oil pressure issues in your Cummins engine. Remember, proper maintenance and regular oil checks are essential for the longevity and performance of your engine. If you’re still experiencing oil pressure problems after performing these steps, it is recommended to consult a professional mechanic for further diagnosis and repairs.

Normal Oil Pressure Range For Cummins Engines

The typical oil pressure range for Cummins engines falls within 10-80 psi, ensuring optimal performance and lubrication. Monitoring oil pressure is crucial for engine longevity and smooth operation, maintaining the engine’s health and efficiency.

`normal Oil Pressure Range For Cummins Engines`

` Oil pressure is a critical aspect of a vehicle’s engine performance, determining the lubrication level and health of vital components. For Cummins engines, understanding the normal oil pressure range is essential to ensure optimal operation and prevent potential issues. Proper oil pressure is crucial for engine longevity and efficiency, making it imperative to monitor and maintain within the specified range. ``understanding Oil Pressure Specs`

` Factors Impacting Oil Pressure: – Engine Load – Oil Viscosity – Ambient Temperature – Worn Bearings – Oil Pump Efficiency – Oil Filter Condition – Engine RPM Maintaining Adequate Oil Pressure: – Regular Oil Changes – Check Oil Level – Monitor for Leaks – Address Warning Lights – Use Recommended Oil Grade Proper oil pressure is the lifeblood of a Cummins engine, ensuring smooth operation and longevity. By understanding the factors influencing oil pressure and adhering to maintenance guidelines, you can safeguard your engine’s performance and reliability.

Credit: mypowermanual.com

Preventive Maintenance Tips For Maintaining Optimal Oil Pressure

Proper maintenance of oil pressure is critical to ensuring the longevity and performance of your Cummins engine. By adhering to preventive maintenance tips, you can help maintain optimal oil pressure and avoid potential issues. Below are essential guidelines to consider for preserving proper oil pressure in your Cummins engine.

Regular Oil Changes

Regular oil changes are fundamental in maintaining optimal oil pressure. Clean, high-quality oil provides proper lubrication, which is vital for reducing friction and heat within the engine. This prevents wear and tear, helping to sustain the required oil pressure levels.

Monitoring Oil Pressure Regularly

Monitoring oil pressure regularly is crucial for identifying any deviations from the norm. An oil pressure gauge can be used to keep track of pressure levels, allowing for early detection of potential problems. Any sudden fluctuations can signal the need for immediate attention and can prevent severe damage to the engine.

Seeking Professional Help For Persistent Oil Pressure Problems

When dealing with persistent oil pressure problems in your Cummins engine, it’s essential to seek professional assistance to diagnose and resolve the issues effectively. Ignoring oil pressure problems can lead to serious engine damage and safety hazards. In this blog post, we’ll explore the importance of consulting certified mechanics and utilizing diagnostic tools to address Cummins oil pressure issues.

Consulting Certified Mechanics

Consulting certified mechanics is crucial when experiencing persistent oil pressure problems in your Cummins engine. Certified mechanics have the expertise and training to identify and resolve oil pressure issues effectively, ensuring the optimal performance and longevity of your engine.

Utilizing Diagnostic Tools

Utilizing diagnostic tools is essential for accurately assessing oil pressure problems in your Cummins engine. Diagnostic tools enable mechanics to conduct thorough inspections and pinpoint the root cause of the issues, leading to precise repairs and preventive maintenance measures.

Frequently Asked Questions Of Cummins Oil Pressure

What Is Normal Oil Pressure For Diesel Engine?

The normal oil pressure for a diesel engine can vary depending on the specific engine model and its operating conditions. However, in general, a normal oil pressure range for a diesel engine is between 30 to 50 psi (pounds per square inch).

Proper oil pressure ensures proper lubrication and smooth performance of the engine.

Is 70 Psi High Oil Pressure?

70 psi is considered high oil pressure. It is important to monitor oil pressure to ensure it remains within the manufacturer’s recommended range. High oil pressure can be a sign of a problem, such as a clogged oil filter or a faulty oil pressure relief valve.

What Is The Oil Pressure Spec For A Cummins Isx?

The oil pressure spec for a Cummins ISX is typically around 25 to 40 psi at idle.

What Is Normal Idle Oil Pressure?

Normal idle oil pressure for a diesel engine ranges from 20 to 40 psi.

Conclusion

Understanding the normal oil pressure for a Cummins engine is vital for proper maintenance. Referencing resources like forums and expert advice can help troubleshoot any oil pressure issues efficiently. Keeping an eye on oil pressure levels is crucial for the longevity and performance of your Cummins engine.