Best Tools for Powerstroke High Pressure Oil Pump Replacement: Easy Installation

Featured image for this comprehensive guide about Best tools for Powerstroke high pressure oil pump replacement

The distinctive growl of a Powerstroke engine is music to many ears, symbolizing power, reliability, and sheer capability. However, even these titans of torque can encounter issues, and one of the most notorious challenges for any Powerstroke owner or mechanic is the dreaded High-Pressure Oil Pump (HPOP) failure. The HPOP is the heart of your engine’s fuel injection system, and when it falters, your Powerstroke can quickly go from a roaring beast to a costly paperweight. Replacing this critical component isn’t a task for the faint of heart, nor for the ill-equipped. It demands precision, patience, and most importantly, the right arsenal of tools.

Attempting a **Powerstroke high pressure oil pump replacement** without the proper equipment is a recipe for frustration, stripped bolts, damaged parts, and potentially even more expensive repairs. Imagine being halfway through the job, only to realize you lack a specialized socket, or struggling to remove a stubbornly seized component with an inadequate tool. This isn’t just about saving time; it’s about performing the repair correctly, ensuring the longevity of your engine, and maintaining your peace of mind. Whether you’re a seasoned diesel technician or an ambitious DIY enthusiast, having the **best tools for Powerstroke HPOP replacement** is non-negotiable.

This comprehensive guide is your ultimate resource for navigating the complexities of HPOP replacement. We’ll delve into the essential general hand tools, critical specialty tools, and indispensable diagnostic equipment that will make your **Powerstroke oil pump replacement** go as smoothly as possible. From understanding the nuances of different Powerstroke generations (7.3L, 6.0L, 6.4L, 6.7L) to providing actionable tips, we’ll equip you with the knowledge and the tool list to confidently tackle one of the most challenging Powerstroke repairs. Let’s gear up and get that Powerstroke back on the road!

Quick Answers to Common Questions

What’s the absolute must-have specialty tool for Powerstroke high pressure oil pump replacement?

You’ll definitely want a good fan clutch wrench set; it makes removing the fan incredibly easy, which is often the first big hurdle for a Powerstroke high pressure oil pump replacement.

Can I really do a Powerstroke high pressure oil pump replacement myself without super expensive tools?

Absolutely! While some specialty tools help, a solid set of standard and metric sockets, wrenches (especially E-Torx), and a good torque wrench will get you through most of the Powerstroke high pressure oil pump replacement job.

Are there any tools I might forget but are crucial for a smooth Powerstroke high pressure oil pump replacement?

Don’t overlook a good set of picks and a magnetic retriever tool; they’re lifesavers for fishing out dropped bolts or seals during your Powerstroke high pressure oil pump replacement. A sturdy creeper also makes working underneath much more comfortable!

What about getting to the pump – do I need anything big like an engine hoist for Powerstroke high pressure oil pump replacement?

For most Powerstroke high pressure oil pump replacement jobs, you won’t need an engine hoist. However, reliable jack stands and a floor jack are essential for safe access, and clear lighting is incredibly helpful.

What’s the biggest time-saver tool for Powerstroke high pressure oil pump replacement?

Without a doubt, a good quality air impact wrench (or powerful electric impact) with the correct E-Torx sockets will drastically cut down on the time and effort required for your Powerstroke high pressure oil pump replacement.

📋 Table of Contents

- Understanding Your Powerstroke HPOP & Why It Fails

- Essential General Hand Tools for HPOP Replacement

- Powerstroke-Specific Specialty Tools You Can’t Live Without

- Diagnostic Tools: Pinpointing the Problem Before You Start

- Safety Gear and Shop Supplies: Don’t Overlook These!

- Step-by-Step Tool Application & Actionable Tips

- Powerstroke HPOP Specialty Tool Recommendations by Engine

- Conclusion: Empower Your Powerstroke Repair

Understanding Your Powerstroke HPOP & Why It Fails

Before diving into the tools, it’s crucial to understand what the HPOP does and why it’s a common failure point across Powerstroke engines. This foundational knowledge will underscore why having the right **Powerstroke HPOP replacement tools** is paramount.

The Role of the HPOP

In all Powerstroke engines (7.3L, 6.0L, 6.4L, and 6.7L), the High-Pressure Oil Pump is responsible for generating the immense oil pressure (ranging from 500 PSI to over 4,000 PSI, depending on the engine and load) required to operate the fuel injectors. This “injection control pressure” (ICP) is vital for atomizing diesel fuel within the combustion chambers. Essentially, the HPOP uses engine oil to hydraulically actuate the fuel injectors, a system known as HEUI (Hydraulically actuated Electronic Unit Injector) in the earlier 7.3L and 6.0L, and a similar principle in later models.

| Tool Name | Primary Function | Key Benefit / Notes | Typical Cost Range |

|---|---|---|---|

| HPOP Removal Socket / Crowfoot Wrench | Loosens/tightens HPOP fittings and pump mounting bolts. | Often specialized (e.g., 7.3L 36mm, 6.0L specific crowfoot) to access confined spaces and prevent fastener damage. | $20 – $80 |

| Torque Wrench (1/2″ Drive) | Ensures proper fastener torque for HPOP, lines, and cover plates. | Critical for high-pressure systems to prevent leaks and damage. Aim for ±3-4% accuracy for reliability. | $60 – $200 |

| Oil Filter Housing Cap Wrench | Removes the oil filter housing cap (e.g., 6.0L) for HPOP reservoir access. | Specific design prevents damage to plastic/aluminum caps. Essential for many Powerstroke layouts that require reservoir draining. | $15 – $40 |

| Assorted Socket & Ratchet Set (3/8″ & 1/2″ Drive) | General fasteners for covers, brackets, and hoses. | Versatile set with common metric and SAE sizes. Look for durable Cr-V or Cr-Mo steel. Ratchets improve speed and leverage. | $80 – $300 |

| Magnetic Pick-up Tool & Inspection Mirror | Retrieving dropped bolts/nuts; inspecting hidden areas for leaks or proper seating. | Invaluable in tight engine bays where visibility is limited, preventing lost parts and ensuring thorough assembly. | $10 – $30 |

Common Symptoms of HPOP Failure

An ailing HPOP typically announces itself with clear symptoms:

- No Start / Extended Crank: The most common and frustrating symptom. If the engine can’t build sufficient ICP, it won’t start.

- Rough Idling or Stalling: Inconsistent oil pressure can lead to erratic engine operation.

- Loss of Power / Hesitation: The engine struggles to deliver power, especially under load.

- Check Engine Light: Diagnostic Trouble Codes (DTCs) related to low ICP (e.g., P2285, P2287, P1211, P1212) are tell-tale signs.

- Oil Leaks: External leaks from the pump itself or its connections.

Why the Right Tools Matter for HPOP Replacement

The HPOP is often buried deep within the engine bay, surrounded by other critical components and tight clearances. Its removal and installation often involve delicate seals, high-pressure fittings, and specific torque specifications. Using incorrect or subpar tools can lead to:

- Stripped Fasteners: The last thing you want on a critical, high-torque component.

- Damaged HPOP or Engine Components: Improper leverage or force can crack housings, bend lines, or damage sensors.

- Oil Leaks: Inadequate sealing or improper torque can lead to persistent and costly oil leaks after the repair.

- Wasted Time and Money: Repeated attempts, broken tools, or a botched job mean more downtime and expenses.

Investing in the **best tools for Powerstroke high pressure oil pump replacement** isn’t just an expense; it’s an investment in a successful, reliable repair and the longevity of your Powerstroke.

Essential General Hand Tools for HPOP Replacement

While many of these tools might already be in your toolbox, their quality and availability are non-negotiable for a smooth **Powerstroke HPOP replacement**. Don’t underestimate the value of reliable, durable hand tools.

Socket and Ratchet Sets

You’ll need both standard (SAE) and metric socket sets, covering a range from small (7mm/1/4″) to large (24mm/15/16″). Deep sockets are particularly useful for nuts on studs or extended bolts. Ratchets in 1/4″, 3/8″, and 1/2″ drive sizes, along with extensions of various lengths and universal joints, will be invaluable for reaching fasteners in tight spots. Quality matters here – cheap sockets can round off critical fasteners, turning a simple removal into a nightmare.

Wrench Sets (Combination, Flare Nut)

Combination wrenches (open-end and box-end) in both SAE and metric sizes will be used frequently. More specifically, a good set of flare nut wrenches is absolutely critical for disconnecting the high-pressure oil lines without rounding off the fittings. These lines operate under extreme pressure, and damaged fittings are a serious safety and reliability concern.

Screwdrivers and Pry Bars

A variety of flathead and Phillips head screwdrivers will be needed for electrical connectors, clamps, and panel removal. Small, sturdy pry bars or trim removal tools are excellent for gently separating components that might be stuck or for prying up stubborn seals without causing damage.

Torque Wrench (Crucial for HPOP)

This is arguably one of the most important tools. The HPOP and its associated components (lines, sensors, mounting bolts) have very specific torque specifications. Overtightening can strip threads or crack housings, while undertightening can lead to leaks or component failure. You’ll likely need a 3/8″ drive torque wrench for lower-value settings and a 1/2″ drive for higher-value settings. Don’t skip this. A digital torque wrench offers precision and ease of use.

Shop Lights and Inspection Mirrors

The engine bay of a Powerstroke can be a dark, cramped place. High-quality LED work lights, headlamps, and small inspection mirrors (telescoping, illuminated) will help you see every fastener, connection, and potential issue, preventing missed steps or accidental damage. Visibility is key when performing a precise operation like **high pressure oil pump replacement**.

Powerstroke-Specific Specialty Tools You Can’t Live Without

This is where the real investment begins, and where you separate the casual mechanic from someone prepared for a **Powerstroke high pressure oil pump replacement**. These specialized tools are designed to fit unique Powerstroke components, ensuring safe and efficient removal and installation.

HPOP Removal/Installation Tool

For some Powerstroke models, particularly the 7.3L, the HPOP is gear-driven and requires a specialized puller for removal and an installer to properly seat it. Trying to pry it off can damage the pump or the engine front cover. Ensure you get the correct tool for your specific engine generation. For 6.0L and 6.4L, the HPOP sits in a valley and is bolted down, so a specific removal tool might not be required in the same way, but access tools are still vital.

ICP Sensor Socket

The ICP (Injection Control Pressure) sensor is typically located in a tight spot, often on the HPOP or on the oil rail. A standard deep socket may not fit or provide the necessary leverage without damaging the sensor or surrounding wiring. A specific offset or deep-well ICP sensor socket makes removal and installation much easier and safer. This is a must-have for any **7.3 Powerstroke HPOP replacement** or similar tasks on other generations.

IPR Socket

The IPR (Injection Pressure Regulator) valve is crucial for controlling the oil pressure from the HPOP. It’s often threaded deep into the HPOP or the oil manifold. Due to its recessed location and sometimes close proximity to other components, a dedicated IPR socket (often a deep, thin-walled, or specialized offset design) is essential to remove and install it without stripping the threads or damaging the valve.

Oil Rail Adapters/Plugs (for Air Tests)

Before replacing an HPOP, you often need to diagnose leaks in the high-pressure oil system. This involves introducing shop air into the oil rails to listen for leaks. For this, you’ll need specialized adapters that screw into the oil rails (sometimes replacing the ICP sensor or dummy plugs) and allow you to connect an air hose. These are indispensable diagnostic **Powerstroke oil pump replacement tools**.

High-Pressure Oil Line Disconnect Tools

While flare nut wrenches handle some connections, certain Powerstroke high-pressure oil lines (especially on 6.0L and 6.4L) might have quick-disconnect or specialty fittings that require specific tools for safe and damage-free separation. Research your specific engine’s line connections before starting.

Fuel Filter Wrench (for certain models)

On some Powerstroke models, accessing the HPOP might involve removing the fuel filter housing or other fuel system components. A dedicated fuel filter wrench ensures you can remove and reinstall the filter without damage, especially if it’s a cartridge type.

Diagnostic Tools: Pinpointing the Problem Before You Start

A common mistake is to immediately assume the HPOP is the problem without proper diagnosis. Many symptoms of HPOP failure can mimic issues with other components (e.g., IPR valve, ICP sensor, oil leaks in the standpipes or dummy plugs, or even low oil levels). Diagnostic tools are the first and most critical step in any **Powerstroke high pressure oil pump replacement** procedure, saving you time and money by ensuring you’re replacing the correct part.

OBD-II Scanner with Diesel-Specific Capabilities

A basic OBD-II scanner can read and clear generic codes, but for a Powerstroke, you need a scanner capable of reading enhanced or manufacturer-specific codes and, crucially, live data streams. Look for scanners that can monitor ICP actual, ICP desired, IPR duty cycle, engine oil temperature (EOT), and engine RPM. Analyzing these parameters during cranking and running conditions is paramount for diagnosing HPOP issues. Tools like Forscan (with an appropriate adapter) or more professional diagnostic scan tools are excellent choices for **Powerstroke HPOP diagnostics**.

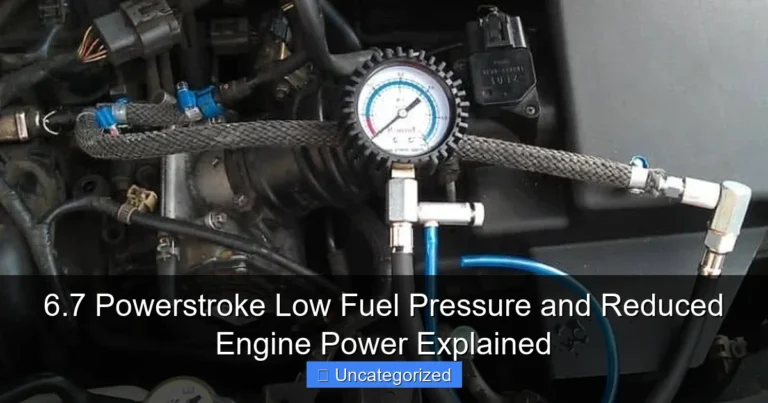

High-Pressure Oil System Tester (Gauge)

This is a specialized gauge that connects directly into the high-pressure oil system (often at the ICP sensor port) to provide a direct reading of the oil pressure the HPOP is producing. This bypasses any faulty sensors and gives you an absolute measurement. It’s an invaluable tool for confirming an HPOP failure, especially if the ICP sensor itself is suspect.

Air Compressor and Regulator (for Air Testing)

As mentioned before, an air compressor is used in conjunction with oil rail adapters to perform a “bubble test” or simply listen for air leaks within the high-pressure oil system. A regulator is essential to control the air pressure, typically keeping it below 150-200 PSI to avoid damage while still being high enough to pressurize the system and reveal leaks. This helps identify internal leaks in the oil rails, standpipes, dummy plugs, or even injector O-rings – issues that can mimic HPOP failure.

Multimeter (for Electrical Checks)

A good quality digital multimeter (DMM) is essential for checking electrical connections, sensor voltages, and wiring integrity. You’ll use it to check the resistance of the IPR valve, ensure proper voltage supply to sensors, and trace any electrical gremlins that might be contributing to your Powerstroke’s issues. Many “HPOP” problems are, in fact, electrical failures upstream of the pump itself.

Safety Gear and Shop Supplies: Don’t Overlook These!

While not “tools” in the traditional sense, these items are just as critical for a safe, clean, and successful **Powerstroke high pressure oil pump replacement**. Ignoring them can lead to injury, a messy workspace, or a compromised repair.

Personal Protective Equipment (PPE)

- Safety Glasses/Goggles: Absolute must-have. Oil, fuel, and metal debris can cause serious eye injury.

- Gloves: Nitrile or mechanic’s gloves protect your hands from oil, fuel, and sharp edges.

- Long Sleeves/Protective Clothing: To protect skin from oil, grime, and potential burns.

- Hearing Protection: If using air tools or an air compressor for an extended period.

Shop Rags and Cleaners

Diesel engines are notoriously messy, and an HPOP replacement involves significant oil exposure. Keep a generous supply of shop rags on hand for spills, cleaning parts, and wiping down your workspace. Brake cleaner or a good quality engine degreaser will be invaluable for cleaning surfaces before reassembly, ensuring proper sealing and identifying any potential post-repair leaks. Cleanliness around the high-pressure oil system is paramount to prevent contamination.

Fluid Drain Pans

You will be draining engine oil, and potentially some fuel, during this process. Ensure you have large, sturdy drain pans to catch all fluids. Depending on your Powerstroke, you might need to drain a significant amount of oil, so plan accordingly.

Thread Sealant and Loctite (if applicable)

Some fittings and bolts, especially those related to high-pressure oil, require specific thread sealants to prevent leaks. Always consult your service manual. Similarly, certain mounting bolts might require thread lockers (like Loctite) to prevent them from vibrating loose over time. Having these on hand, as specified by the manufacturer, is crucial for a reliable repair.

Replacement O-rings and Gaskets

Never reuse old O-rings or gaskets in the high-pressure oil system. Always have a complete set of new O-rings for the HPOP, oil lines, ICP sensor, IPR valve, and any other components you disconnect. These small, inexpensive parts are absolutely vital for preventing leaks and maintaining proper oil pressure.

Step-by-Step Tool Application & Actionable Tips

Now that you’re armed with the knowledge of the **best tools for Powerstroke high pressure oil pump replacement**, let’s look at how they fit into the actual process, along with some actionable tips to ensure success.

Pre-Removal Diagnostics

- Connect OBD-II Scanner: Start by reading codes and live data. Monitor ICP_ACT, ICP_DES, and IPR% during cranking. If ICP_ACT doesn’t reach at least 500 PSI (for 7.3L/6.0L) during crank, you have an HPOP system issue.

- Air Test the High-Pressure Oil System: Use your air compressor and oil rail adapters. Pressurize the system and listen for leaks around injectors, standpipes, dummy plugs, and the HPOP itself. This is crucial for distinguishing between an HPOP failure and a high-pressure oil leak elsewhere. A common culprit on 6.0L are the STC fitting (Snap-To-Connect) and dummy plugs/standpipes.

- Check Electrical Components: Use your multimeter to check the resistance of the IPR valve and verify voltage to the ICP sensor.

Tip: Document all readings and findings. This not only helps with diagnosis but provides a baseline for comparison after the repair.

Disassembly Phase Tools

This phase involves removing components to gain access to the HPOP. Tools needed will vary slightly by Powerstroke model, but generally include:

- Socket and Ratchet Sets: For intake manifold bolts, valve covers, fuel lines, and various brackets.

- Wrench Sets (especially flare nut wrenches): For disconnecting high-pressure oil lines without damage.

- Screwdrivers and Pry Bars: For electrical connectors, hose clamps, and stubborn components.

- Fluid Drain Pans: To catch engine oil as components are removed.

- Shop Rags: For containing spills and keeping the work area clean.

- HPOP Removal Tool (7.3L specific): Essential for safely extracting the 7.3L HPOP from its gear.

- ICP/IPR Sockets: For removing these sensors from the HPOP or oil rails.

Tip: Label everything! Use plastic bags and a marker to label bolts, electrical connectors, and small parts according to their location. Take photos or videos as you disassemble. This will save immense time during reassembly.

Installation Phase Tools

Reinstallation is where precision truly pays off. You’ll be largely reversing the disassembly process, but with a critical focus on torque and cleanliness.

- Torque Wrench: Absolutely essential. Every bolt, from the intake manifold to the HPOP mounting bolts and oil line fittings, has a specific torque spec. Adhering to these prevents leaks and ensures component integrity.

- New O-rings and Gaskets: Always use new seals for the HPOP, oil lines, ICP, IPR, and any other disturbed components. Apply a thin layer of clean engine oil to O-rings before installation to prevent pinching and aid seating.

- Thread Sealant/Loctite: As per manufacturer specifications, apply thread sealant to any pipe thread fittings (e.g., some ICP sensor threads) and Loctite to specified bolts.

- Specialty Sockets (ICP/IPR): For careful reinstallation of sensors.

Tip: When installing high-pressure oil lines, start all fittings by hand to ensure they are not cross-threaded before using a wrench. Torque them to spec, then visually inspect for proper seating.

Post-Installation Checks

- Fill with Oil: Ensure your engine oil level is correct.

- Prime the System: Crank the engine for several short bursts (without allowing it to start, by unplugging the cam sensor or injector harness) to allow the HPOP to re-prime the system and build pressure.

- Start the Engine: Once primed, attempt to start. Listen for abnormal noises and immediately check for oil leaks.

- Monitor with Scanner: Reconnect your OBD-II scanner and monitor ICP_ACT, ICP_DES, and IPR%. Ensure ICP_ACT is meeting ICP_DES and IPR% is within normal operating range.

Tip: After the first run, let the engine cool, then re-check all accessible high-pressure oil fittings for leaks and re-torque if necessary (some components have a “torque-to-yield” spec that doesn’t allow re-torqueing, so always check your manual).

Powerstroke HPOP Specialty Tool Recommendations by Engine

While many tools are universal, some are specific to different Powerstroke generations. Here’s a quick guide to highlight key specialty **Powerstroke HPOP tools** you might need based on your engine.

| Powerstroke Engine | Key Specialty Tools for HPOP Replacement | Typical HPOP Location |

|---|---|---|

| 7.3L (1994.5-2003) | HPOP Puller/Installer, ICP Sensor Socket (often deep/offset), IPR Socket, High-Pressure Oil Line Wrenches (flare nut). | Front of the engine, behind the timing cover, driven by the cam gear. |

| 6.0L (2003-2007) | STC Fitting Tool (Snap-To-Connect), Standpipe/Dummy Plug Removal Tools, IPR Socket, ICP Sensor Socket, High-Pressure Oil Rail Adapters for air testing. | In the engine valley, under the intake manifold, driven by the cam. |

| 6.4L (2008-2010) | High-Pressure Fuel Pump (HPFP) Removal Tools (though this is more fuel side, often confused), IPR Socket, ICP Sensor Socket, specialized fuel line disconnects. (Note: 6.4L uses a CP4 HPFP for fuel, still relies on engine oil for injectors, but the “HPOP” role is different). | HPFP is on the passenger side of the engine block. |

| 6.7L (2011-Present) | Specialized HPFP tools (CP4 pump – fuel side, not engine oil), high-pressure fuel line wrenches/disconnects. (Note: 6.7L is a common rail system; no traditional HPOP, but HPFP failures are common, requiring different specialized tools.) | HPFP typically mounted on the engine, driven off the timing chain. |

Disclaimer: This table is a general guide. Always consult your specific model’s service manual for precise tool requirements and procedures. The 6.4L and 6.7L systems are significantly different from the 7.3L and 6.0L HEUI systems, requiring a different set of **high pressure oil pump replacement tools** for their respective fuel pump systems.

Conclusion: Empower Your Powerstroke Repair

Tackling a **Powerstroke high pressure oil pump replacement** is a significant undertaking, but it’s a repair that many dedicated owners and technicians successfully complete. The key differentiator between a frustrating, drawn-out ordeal and a smooth, efficient job lies squarely in preparation and having the right equipment. As we’ve explored, this isn’t just about a few wrenches; it’s about a comprehensive toolkit, including general hand tools, Powerstroke-specific specialty tools, crucial diagnostic equipment, and essential safety gear.

By investing in the **best tools for Powerstroke HPOP replacement**, you’re not just buying metal; you’re investing in accuracy, efficiency, and the long-term health of your diesel engine. You’ll minimize the risk of damage, reduce repair time, and gain the confidence that comes from performing a job correctly. So, before you grab that first wrench, take the time to gather every tool on this list. Your Powerstroke will thank you with many more miles of reliable, powerful performance. Arm yourself with knowledge and the right tools, and you’ll be ready to conquer any HPOP challenge your Powerstroke throws your way.

🎥 Related Video: How To Check HPOP Oil 7.3 Powerstroke!

📺 Joshua Overman

Frequently Asked Questions

What are the fundamental hand tools required for a Powerstroke high pressure oil pump replacement?

You’ll definitely need a comprehensive socket and wrench set, including both standard and metric sizes, along with various extensions and swivel adapters. A good set of ratchets, screwdrivers, and pliers will also be essential for disassembling components and accessing the HPOP.

Are there any specialized tools critical for a smooth Powerstroke high pressure oil pump replacement?

Yes, a crucial specialized tool is an HPOP line disconnect tool, especially for 7.3L engines, to safely release the high-pressure oil lines without damage. For some applications, a robust pick set can be invaluable for removing stubborn O-rings and seals around the HPOP.

Do I need diagnostic tools before or after replacing my Powerstroke high pressure oil pump?

Absolutely, a diagnostic scan tool capable of monitoring live data is highly recommended. This allows you to check for proper Injector Control Pressure (ICP) and Injector Pressure Regulator (IPR) values before the repair, and to confirm system functionality and bleed air after the new HPOP is installed.

What tools can make the Powerstroke HPOP replacement process more efficient and less frustrating?

Impact wrenches and ratchets can significantly speed up the removal of bolts, while flexible extensions and wobble sockets are invaluable for reaching fasteners in tight spaces. A strong magnetic pickup tool and a good headlamp or work light will also save immense time and prevent lost hardware.

Are there specific tools for handling the seals and gaskets during a Powerstroke high pressure oil pump replacement?

A quality set of O-ring and seal pick tools is essential for carefully removing old seals without damaging mating surfaces. For installing new seals, ensuring cleanliness and using a light coat of clean oil can help, but generally, specific drivers aren’t needed unless dealing with a unique press-fit seal elsewhere in the system.

What safety equipment and preparatory tools should I have ready for a Powerstroke HPOP replacement?

Safety glasses and gloves are non-negotiable to protect against oil, fuel, and sharp edges. You’ll also need plenty of shop rags, a drain pan for any fluid spills, and potentially jack stands and a floor jack if you need to raise the vehicle for better access or to remove other components.