Easy Fixes: How to Get Out a Stripped Oil Drain Plug and Avoid Costly Repairs

Removing a stripped oil drain plug can be a frustrating and costly problem for any car owner. It can happen to anyone, and it’s a highly common issue that can be caused by over-tightening or general wear and tear. Not only can it be time-consuming to remove, but it can also damage the oil pan or engine block if not dealt with correctly.

So, how do you remove a stripped oil drain plug without spending a fortune? In this blog post, we will uncover some of the best techniques for removing the stripped oil drain plug and offer some essential tips for preventing it from happening again. Whether you’re a DIY enthusiast or have no experience with cars, we’ve got you covered. So, grab your tools and let’s get started!

Evaluate the damage

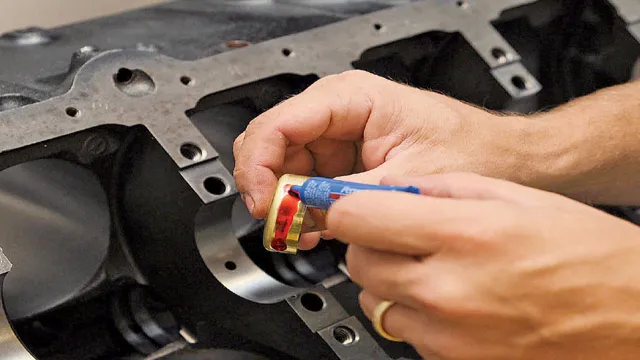

If you have a stripped oil drain plug, it’s important to evaluate the damage before attempting to remove it. The first step is to inspect the threads on the plug and in the oil pan. If the threads on the plug are damaged, then you may need to replace the plug entirely.

If the threads in the oil pan are damaged, then you may need to use a helicoil or tap and die set to repair the threads. It’s best to consult with a professional mechanic if you’re unsure of how to do this properly. Additionally, if the damage is severe, you may need to replace the entire oil pan.

It’s important to address the issue as soon as possible to avoid any further damage to your vehicle’s engine. Remember to always use the correct size socket wrench when removing the plug to prevent future stripping.

Inspect the plug and surrounding area

Inspecting the plug and surrounding area is an essential step in evaluating the damage of electrical appliances. The first thing to look out for is any visible signs of wear and tear on the plug, such as cracks or frayed wires. If there are any such indications, it’s best to replace the plug altogether.

Additionally, it’s necessary to check for any corrosion in the plug or surrounding area. Corrosion can be caused by moisture and often appears as a green discoloration. In such cases, a thorough cleaning might solve the problem.

However, if the corrosion is severe, it could damage the internal wiring of the appliance and require a professional to fix it. Therefore, it’s crucial to evaluate the extent of the damage before trying to fix it on your own. By being observant of these details, you can ensure that any electrical appliances in your home are safe and functional.

Choose the right tools

When dealing with a damaged project, choosing the right tools is essential to properly evaluate the situation. Before you attempt any repairs, it is crucial to determine the extent of the damage. Ask yourself, “What is broken? And how severe is the damage?” This will help you identify the necessary tools and materials needed to address the problem effectively.

Once you’ve assessed the damage, make sure to use the right tools for the job. Don’t just settle for whatever is available or the cheapest option. Poor quality tools can lead to sloppy repairs and even further damage.

Invest in high-quality tools that can withstand heavy use and provide reliable results. By selecting the right tools, you’ll be able to properly diagnose and fix any damage to your project, ensuring a more successful outcome.

Try non-destructive methods

If you’re struggling with a stripped oil drain plug, don’t fret. There are several non-destructive methods you can try to get it out. One option is grabbing a pair of pliers and slowly turning the plug counterclockwise.

Another is using a rubber band or rubber gloves to provide more grip while turning. If these methods don’t work, you can try using an impact driver or a bolt extractor set. Keep in mind that forcing the plug to turn while using these methods can potentially damage your oil pan.

As a last resort, consider taking your vehicle to a mechanic or auto shop for professional assistance. Remember, it’s better to be safe than sorry when it comes to something as important as your car’s oil drainage system.

Use a rubber band

If you’re looking for a non-destructive way to secure loose cords or cables, try using a rubber band. This simple household item can be a game-changer when it comes to keeping cords neat and organized. All you have to do is wrap the rubber band around the cord, creating a small loop that can be used to hold the excess wire in place.

The best part? Rubber bands are easy to remove and won’t damage the cords in any way. This is especially useful if you’re dealing with delicate electronics or expensive equipment. So, don’t wait any longer and try this low-cost and efficient solution to keep your cords under control.

Try an oversized hex key

If you’ve ever found yourself in a situation where a bolt is completely stripped and you can’t seem to get it loose, then you know how frustrating and time-consuming it can be. However, before you go straight to destructive methods, there are a few non-destructive techniques worth trying. One of the methods is to use an oversized hex key.

If you have a hex key that is slightly larger than the stripped bolt head, you can try tapping it into the head of the bolt. The extra friction can sometimes provide the added force needed to loosen the bolt. It’s important to note that this method works best with softer metals like aluminum.

If the bolt is made of a harder material like steel, this method may not be effective. By using this technique, you may be able to save yourself the time, money, and frustration that comes with a stripped bolt.

Use a manual impact driver

When working on DIY projects or fixing household items, it’s essential to use the right tools to avoid damaging the material. One useful tool to have is a manual impact driver, especially when dealing with stubborn screws. Using a hammer and screwdriver can cause damage to the screw and surrounding area, whereas a manual impact driver provides a non-destructive solution.

With a manual impact driver, you apply rotational force to loosen the screw, allowing it to loosen without causing any damage. This tool works well on screws with stripped heads or those that require additional torque to remove. It’s an effective way to ensure that you don’t harm the material you’re working on and allows you to complete your project with ease.

So the next time you’re working on a project and come across a stubborn screw, consider using a manual impact driver as a non-destructive and practical solution.

Go with a destructive method

If you have a stripped oil drain plug and it’s giving you a hard time, there’s no need to panic. One of the most effective solutions is to go with a destructive method. This may sound scary, but it’s actually quite simple.

First, remove as much oil as you can from the engine by loosening the drain plug. Once that’s done, use a hammer and chisel or a drill to create a groove on the side of the plug. This will allow you to use a wrench to turn the plug out.

If the plug is still stuck, you may need to use a bolt extractor. Just make sure to use the right size extractor and apply enough pressure to loosen the plug. Keep in mind that this is a last resort option and should only be done if you’ve exhausted all other methods.

With a destructible method ensuring, you’ll be able to get that stripped oil drain plug out in no time.

Use a screw extractor

If you’re struggling to remove a stubborn or stripped screw, it may be time to break out the big guns and go with a destructive method. Using a screw extractor is a quick and efficient way of removing screws that have become stuck or damaged over time. By drilling a small hole into the center of the screw, you can then insert the extractor and twist it until the screw begins to turn.

Once the screw has been loosened enough, you can then use a pair of pliers or a screwdriver to finish removing it. While this method may seem destructive, it is often the only way to remove stubborn screws without damaging the surrounding material. So, the next time you’re faced with a difficult screw, consider using a screw extractor for a hassle-free removal process.

Drill the plug out

When it comes to removing a stuck plug, sometimes the only way is to drill it out. This can be a destructive method, but it is usually the most effective. First, gather the necessary tools: a drill, a drill bit, and safety goggles.

Then, carefully center the drill bit on the center of the plug and start drilling slowly. Use a little bit of pressure at first and gradually increase it as you go. Keep in mind that you don’t want to damage the surrounding pipes or fittings, so be gentle and patient.

Once you have drilled through the entire plug, remove the drill bit and carefully clean out any debris left behind. While drilling out a plug may not be the ideal solution, it’s often the best way to get the job done and move on with your plumbing repairs.

Prevent future problems

If you’ve ever changed your car’s oil, you know the dread that comes with discovering a stripped oil drain plug. Fortunately, there are a few tricks to get you out of this sticky situation. One way to avoid this scenario is to ensure proper torque when installing the plug.

Use a torque wrench to tighten the plug to the manufacturer’s recommended specifications. Additionally, consider upgrading to a magnetic oil drain plug that’s easier to remove and captures metal debris before it can cause damage. Another trick is to apply penetrating oil to the plug and let it sit for a few hours before attempting to remove it.

If none of these methods work, you can try using a specialized tool like an easy-out or oversized plug to extract the faulty plug. Remember, taking preventative measures and being diligent during the installation process can minimize the likelihood of encountering stripped oil drain plugs in the future.

Replace the drain plug with an oversized version

If you want to prevent future drain plug problems, consider replacing it with an oversized version. This will help protect your engine and its components from potential damage caused by stripped or worn out drain plugs. Oversized drain plugs are slightly larger than standard ones, thereby providing a tighter fit that helps prevent drain plug leaks.

They come in various sizes, so it’s important to choose the right one for your engine. Once you’ve replaced your drain plug, be sure to check for any leaks before driving your car. It’s a simple and cost-effective solution that can help extend the life of your engine.

Overall, oversized drain plugs are a worthwhile investment that can save you from costly repairs down the line.

Switch to a magnetic drain plug

If you’re worried about potential engine problems, one simple upgrade you can make is switching to a magnetic drain plug. These have become increasingly popular in recent years, as they offer an extra layer of protection against metal shavings and other debris in your oil system. The idea is that the magnetized surface of the plug will catch any loose particles before they can cause any damage to your engine.

By taking this precautionary step, you can prevent future problems and save yourself trouble down the road. With a small investment up front, you can potentially avoid costly repairs later on. So if you want to keep your engine running smoothly, consider making the switch to a magnetic drain plug today.

Conclusion

In conclusion, getting out a stripped oil drain plug is no easy feat, but with the right tools and techniques, it can be accomplished. It requires patience, determination, and a bit of creativity. So next time you find yourself stuck with a stubborn stripped drain plug, remember to take a deep breath, channel your inner MacGyver, and give it your all.

Who knows, you might just surprise yourself with your resourcefulness and mechanical prowess. And if all else fails, there’s always the option to call in a professional. Happy wrenching!”

FAQs

What tools do I need to remove a stripped oil drain plug?

You will need an oil filter wrench, vice grip pliers, and a socket wrench with a stripped bolt extractor.

Can I drive my car with a stripped oil drain plug?

It is not recommended to drive your car with a stripped oil drain plug as it may lead to oil leaks and engine damage.

How can I prevent my oil drain plug from getting stripped in the future?

You can prevent a stripped oil drain plug by using a torque wrench to tighten it properly, not over tightening or cross-threading it, and using an anti-seize lubricant.

Will I need to replace my oil pan if the drain plug is completely stripped?

It depends on the severity of the damage. If the drain plug hole is only slightly damaged, it may be possible to install a threaded insert. However, if the hole is heavily damaged, it may be necessary to replace the entire oil pan.