Effortlessly Repair Your Engine with These Expert Tips: Fixing Misaligned Serpentine Belt Made Easy

Have you noticed a squeaking or rattling noise coming from your engine? Or maybe your car is not running as smoothly as it used to be? One thing you might want to check is the serpentine belt. This important component connects various engine parts to keep them running in sync. However, if it becomes misaligned, it can cause a host of problems.

In this blog post, we’ll go over some tips on how to fix a misaligned serpentine belt and keep your car running smoothly on the road. So put on your mechanic hat, and let’s dive in!

Locate the Tensioner

If you’re experiencing issues with your serpentine belt alignment, one of the first steps in fixing it is to locate the tensioner. The tensioner is a spring-loaded pulley that presses against the belt, keeping it tight and on track. Depending on your vehicle model, the tensioner may be located in different positions, so it’s essential to consult your owner’s manual or online resources to find its exact location.

Before inspecting the tensioner, ensure that the engine is off and cool to the touch, as moving parts can be hazardous. Once you’ve located the tensioner, inspect it for any signs of damage or wear, such as cracks or missing pieces. If everything looks intact, use a breaker bar or ratchet to release the tensioner, allowing you to remove the belt and check for any damage or debris.

With proper maintenance and regular inspections, a misaligned serpentine belt can be corrected, ensuring your vehicle’s smooth operation.

Inspect the Belt

When inspecting the belt of your vehicle, one essential step is to locate the tensioner. The tensioner is responsible for maintaining tension on the belt, ensuring that it stays in place and runs smoothly. It’s typically located near the top of the engine and can be identified by its spring-loaded arm.

To locate the tensioner, refer to your vehicle’s manual or search online for a diagram that shows its location. Once you’ve located it, inspect the tensioner for any signs of wear and tear that could cause it to malfunction. Look for cracks or frayed edges, and make sure the arm moves smoothly without any resistance.

If the tensioner needs to be replaced, it’s best to do so as soon as possible to avoid any potential damage to your engine. By regularly inspecting the tensioner, you can help prolong the life of your vehicle and avoid costly repairs down the road.

Check Alignments

When it comes to checking alignments in your vehicle, one important step is locating the tensioner. The tensioner is responsible for making sure that your engine belt stays at the correct tension, which is necessary for proper alignment. If the tensioner is not working properly, your belt can become too loose or too tight, leading to issues with your engine or other systems.

To locate the tensioner, you’ll need to refer to your vehicle’s manual and find the specific location for your make and model. Once you’ve located it, you can check to make sure that it’s functioning properly and adjust it as needed. By taking the time to locate and check the tensioner, you’ll be able to ensure that your vehicle is running smoothly and avoid potential problems down the road.

Adjust the Belt Tensioner

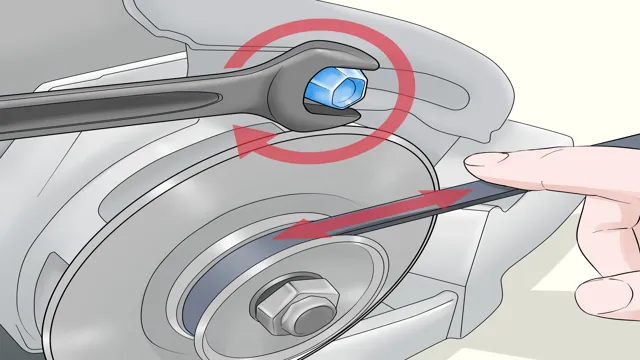

If you hear a squealing noise from under the hood of your car, chances are that the serpentine belt is off track or misaligned. In such cases, one needs to adjust the belt tensioner to fix it. Before you begin, make sure to turn off the engine and let the car cool down.

Identify the belt tensioner and check if it has a locking mechanism or not. If it does, you will need to use a socket wrench to release the lock. Keep in mind to turn the wrench in the direction that loosens the tensioner.

Next, adjust the tensioner until the belt is tight enough as per manufacturer instruction. However, ensure that it isn’t too tight as it could cause premature wear and tear of the belt or other components. Tighten the locking mechanism, if present, and rev the engine a couple of times to check if the belt is still aligned.

Such minor fixes can save you from costly repair bills and prevent long-term damage to your vehicle.

Loosen Tensioner

Adjust Belt Tensioner When your car’s belt tensioner is too tight, you’ll start hearing strange noises from the engine, and it might even affect the performance of your car. The good news is that adjusting the belt tensioner is a fairly simple task. First, locate the belt tensioner and use a wrench to loosen the bolt holding it in place.

Once that’s done, use a pry bar to move the tensioner in the direction that loosens the belt. Once the belt is loose enough, you can use your hands to remove it. Finally, adjust the tensioner until the belt is tight enough, and then reattach it.

It’s important to remember not to tighten the belt too much, as this can cause damage to the belt and other parts of the engine. By adjusting the belt tensioner, you can keep your car running smoothly and avoid costly repairs down the line.

Adjust Belt Position

When it comes to maintaining your car, one task that you may need to tackle periodically is adjusting the belt tensioner. This is an important task because the belt tensioner helps to keep your car’s belts at the proper tension, which in turn helps to ensure that your engine runs smoothly. To adjust the belt tensioner, start by locating it under the hood of your car.

Then, use a wrench to turn the adjustment bolt until the belt is at the desired tension. It’s important to make sure that the tension is not too loose or too tight, as both can cause problems with your car’s performance. So, take your time and make sure that the tension is just right.

By keeping your belt tensioner in good working order, you can help to ensure that your car runs smoothly and reliably for years to come.

Tighten Tensioner

Adjusting the belt tensioner is necessary to maintain proper belt tension and ensure proper function of the engine components. The tensioner keeps the belt at the right tension, which is crucial for the smooth operation of the engine. To adjust the tensioner, first, locate it in the engine compartment.

Then, using a wrench, turn the adjustment bolt either clockwise or counterclockwise, depending on the make and model of your vehicle. Once you have reached the desired tension, tighten the lock nut to keep the bolt in place. Make sure to check the belt tension periodically and adjust the tensioner if necessary.

Failure to maintain proper belt tension can lead to premature wear on engine components, which can be costly to repair in the long run. By adjusting the tensioner, you can prolong the life of your engine and keep your vehicle running at its best.

Test Alignment

Are you having trouble with a misaligned serpentine belt? It’s essential that your serpentine belt is properly aligned to ensure your vehicle runs smoothly and efficiently. A misaligned belt can cause a variety of problems, such as squeaking noises, reduced engine power, and eventually, a broken belt. Fortunately, fixing a misaligned belt isn’t a difficult task.

The first step is to inspect the belt for any damage, such as cracks or fraying. If the belt appears to be in good condition, then you’ll need to adjust the tensioner to fix the alignment. To do this, loosen the bolts on the tensioner, adjust the position of the tensioner, then tighten the bolts back up.

It’s important not to over-tighten the belt, as this can cause damage as well. Once the belt is properly aligned, start your vehicle and listen for any abnormal noises or vibrations. If everything sounds and feels good, then you’re back on track!

Start the Engine

If you’re having trouble starting your engine, don’t worry – it’s a common problem that many drivers face. There are a few things you can try before calling a mechanic. First, make sure you’re pressing down on the gas pedal while turning the key.

If that doesn’t work, try jumping your battery with another car. Just make sure to connect the cables in the right order and keep the cables away from any moving parts in both cars. Another possibility is to check your fuel level – if it’s low, fill up your tank and try starting the engine again.

If none of these solutions work, it may be time to take your car into the shop. Don’t hesitate to call a professional if you’re stuck – they have the knowledge and tools to diagnose and fix any issues with your engine. Remember, taking care of your car is important to keep it running smoothly and safely on the road.

Observe Belt Movement

When it comes to maintaining your conveyor system, one crucial aspect to pay attention to is the alignment of the belt. This means making sure that the belt is running straight and centered on the conveyor track. To test the alignment, you should first observe the movement of the belt as it passes through the system.

If you notice any wobbling, drifting, or slipping, it may be a sign of misalignment. This can lead to increased wear and tear on the belt, as well as decreased efficiency and productivity. To fix the issue, you may need to adjust the idlers or pulleys to ensure that the belt is running smoothly and straight.

Keeping your conveyor belt properly aligned will not only extend its lifespan but also save you from costly repairs and downtime in the long run. So, be sure to regularly inspect and maintain your conveyor system to ensure its optimal performance and longevity.

Final Thoughts

In conclusion, fixing a misaligned serpentine belt may seem like a daunting task, but with proper guidance and tools, it can be accomplished with ease. It is essential to identify the source of the misalignment, whether it is due to a worn-out tensioner or a damaged pulley. Once the source of the issue is identified, it is crucial to fix or replace the faulty component.

Additionally, ensuring the proper tension of the belt is essential to prevent future misalignments. Take the time to inspect the belt and all components regularly to prevent future issues. In summary, fixing a misaligned serpentine belt requires attention to detail and regular maintenance, but it can save you from more expensive vehicle repairs down the road.

Conclusion

In summary, fixing a misaligned serpentine belt requires a bit of finesse and a lot of patience. You’ll need to carefully assess the belt’s position and ensure that all pulleys are aligned properly. Just like a game of Jenga, one wrong move can topple the entire tower and cause further damage.

So take your time, use the right tools, and exercise caution throughout the process. And remember, always keep your belt (and your puns) aligned for a smooth ride!”

FAQs

What causes a misaligned serpentine belt?

A misaligned or wrongly installed pulley can lead to a misaligned serpentine belt.

What are the symptoms of a misaligned serpentine belt?

The engine may produce a squealing noise, the belt may wear out quickly, and the accessories powered by the belt may not function properly.

How do you know if your serpentine belt is misaligned?

One way to check for misalignment is to inspect the belt path and pulley alignment. Another way is to observe the movement of the belt while the engine is running.

How do you fix a misaligned serpentine belt?

The first step is to identify the cause of misalignment. If it is a damaged or worn pulley, it must be replaced. If it is a misaligned pulley, it may need to be adjusted or repositioned.