Learn How to Seamlessly Fix a Hole in Your Oil Pan Like A Pro!

If you’re a car owner, you know how frustrating it can be when the oil pan develops a hole. It’s a common problem that can cause major damage to your car’s engine if not handled quickly. Luckily, fixing a hole in an oil pan is not rocket science.

With the right tools, time, and patience, you can fix the problem and get back on the road in no time. In this blog post, we will walk you through the steps you need to take to fix a hole in an oil pan. Whether you’re a seasoned mechanic or a novice at car repairs, we’ve got you covered.

Assessment of the Damage

If you find yourself with a hole in your oil pan, the first step is to assess the damage. Take a good look at the size and location of the hole. If it’s small enough, you might be able to fix it with a simple patch kit.

However, if the hole is quite large or in a difficult-to-reach area, you may need to replace the entire oil pan. It’s also important to check for any other damage that may have been caused by the hole, such as leaks or engine problems. If you’re unsure about the extent of the damage, it’s always best to consult with a professional mechanic.

They can give you an accurate assessment and recommend the best course of action for repairing your oil pan.

Locating the Hole

When dealing with a damaged object, it is important to assess the problem thoroughly before jumping to a solution. In the case of a hole, the first step is to locate its position and measure its size. This is especially important if you are repairing a hole in a surface such as drywall or wood, as you will need to cut out a piece of matching material to patch the affected area.

For larger holes, you may need to use a template to ensure that the replacement piece fits perfectly. It’s also important to consider the cause of the damage, as this can indicate the likelihood of it occurring again in the future. By taking the time to properly assess the situation, you’ll be able to make informed decisions about how best to repair the hole and prevent it from happening again in the future.

Checking for Additional Damage

When assessing property damage, it’s essential to check for any additional issues that may have occurred. It’s not uncommon for hidden damage to exist, especially in water or fire damage situations. Some damage may not be visible to the naked eye, and it’s important to have a professional inspection to identify any potential issues.

In addition, it’s essential to check for any structural damage that may have occurred, which could compromise the safety of the building. The assessment of the damage should be thorough, taking into consideration all factors that could have contributed to the damage. By identifying any additional problems, you can ensure that they are dealt with promptly, preventing further damage and ensuring the safety of the building.

So, if you’re dealing with property damage, make sure to have a professional assessment to identify any hidden damage.

Preparation for Repair

If you’ve noticed a hole in your oil pan, it’s essential to act fast to prevent oil leaks that could damage your engine. The first step is to prepare the area for repair. Begin by draining all the oil from your engine to avoid getting it on yourself or the surrounding environment.

Next, use a degreaser to clean the area around the hole thoroughly. You’ll want to ensure that the surface is completely clean and dry before proceeding. Once the area is free from debris, sand the surface around the hole so that the epoxy or putty used for repair can adhere correctly.

Start with a rough-grit sandpaper and switch to a finer-grit sandpaper to achieve a smooth surface. With your preparation complete, you’re ready to begin the actual repair process and get your vehicle back on the road. Remember always to wear appropriate safety gear and follow proper procedures.

Draining the Oil

One of the most important steps in preparing for an oil change is draining the old oil. Once you’ve parked your car on a level surface and turned off the engine, it’s time to locate the oil drain plug. You can find this beneath the car, near the engine oil pan.

It’s important to have a drain pan ready to catch the old oil as it flows out. Before loosening the plug, make sure your pan is positioned directly beneath it. Then, using a socket wrench, carefully remove the plug and watch as the old oil drains out.

Once all of the oil has been drained, it’s time to replace the drain plug and move onto the next step of the oil change process. By following these simple steps, you’ll be able to successfully prepare your car for a necessary oil change.

Clean the Oil Pan

Preparing for a repair job requires a bit of prep work, and cleaning the oil pan should be at the top of your list. The oil pan is vital to the engine’s health, as it holds the engine’s oil and helps keep it clean. Before you start any repair work, it’s important to drain the oil from the engine completely.

Once the oil has been drained, you can loosen the bolts on the oil pan and carefully remove it from the engine block. Gently scrape off any old gasket material with a scraper to avoid scratching the surface, then clean the oil pan thoroughly with a degreaser and some warm, soapy water. Rinse it clean and be sure it’s completely dry before reattaching it to the engine block.

By taking the time to properly clean the oil pan, you can ensure that the new gasket creates a tight seal and that the engine runs smoothly and efficiently.

Degreasing the Area

Degreasing the area is an essential step in preparing your surface for repair. This is particularly true for surfaces that are exposed to oils, grease, or any other form of contaminants. The process of degreasing involves cleaning the surface with a degreaser or cleaning agent to remove all contaminants, dirt, dust, and grime.

Doing this will help ensure that the repair will adhere well to the surface, and it will also help in achieving a smooth and consistent finish. Degreasing can be done in various ways, including pressure washing, wiping, or using a solvent. Whichever method is used, it’s important to ensure that all the oil and grease are removed completely.

This will not only help with adhesion but also improve the lifespan of the repair. Remember, failing to degrease the area can result in a repair that won’t last as long as it should. So, always make sure to properly clean and degrease the area before any repair work is done.

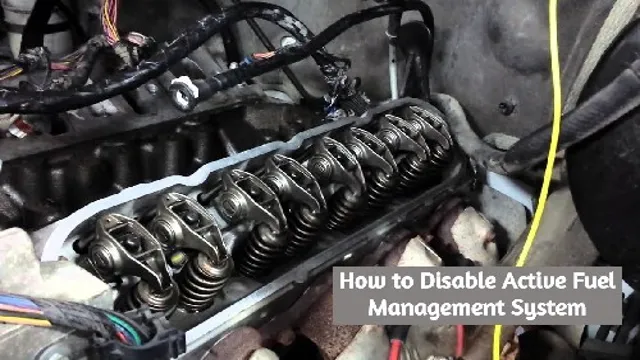

Methods for Repair

If you’re wondering how to fix a hole in your oil pan, there are a few methods you can try. The first option is to use an epoxy putty, which can seal small holes effectively. All you have to do is clean the area around the hole and apply the putty as directed by the manufacturer.

Another option is to use a temporary sealant like JB Weld, which is designed to withstand high temperatures and pressure. If the hole is too large, you may need to replace the oil pan entirely, which is a more expensive and time-consuming process. Still, it’s essential to fix the hole as soon as possible to prevent oil leaks and engine damage.

So, if you notice any signs of a hole in your oil pan, such as a puddle of oil underneath your car, make sure to take action immediately and use one of these methods to repair it.

Welding

Welding is a crucial process in repairing metal structures or components. There are several welding methods that a welder can use for repairs. One of the most common methods is shielded metal arc welding (SMAW), which is best for welding thicker metals.

SMAW is easy to learn, and its equipment is relatively easy to obtain. Another popular method for repairs is gas metal arc welding (GMAW), commonly known as MIG welding. It is perfect for making quick and strong welds and is best for thin metal repairs.

Tungsten inert gas (TIG) welding is another method that is well-suited for repairing thin metals, but it is the most difficult method to learn. When choosing a welding method for repairs, it is crucial to consider factors such as the type of metal being welded, its size, and the skill level of the welder. Overall, each welding method has its advantages and disadvantages, and selecting the right method for a particular repair job can make all the difference.

JB Weld

JB Weld is a reliable and versatile adhesive solution that can fix almost anything. Repairing things using JB Weld is easy, and there are various methods that you can use depending on the type of repair you need. For instance, if you are repairing a small crack on a surface, you can use JB Weld KwikWeld, which is a fast-setting solution that dries within 6 minutes.

However, if you are repairing a larger surface area or bonding two different types of materials together, you will need to use regular JB Weld, which takes up to 24 hours to cure fully. Applying JB Weld is straightforward, and you only need to clean and prepare the surface you want to bond properly. Ensure that you mix the adhesive according to the instructions and apply it evenly on the surfaces you want to bond.

Give it enough time to dry, and your fix will hold up strong for a long time. Overall, JB Weld offers a reliable, affordable, and efficient way of repairing all sorts of broken items around your home, car, or workplace. So, next time you need to fix something, try using JB Weld and enjoy the results.

Epoxy Method

When it comes to repairing concrete surfaces, one of the more effective methods is the epoxy method. This entails applying an epoxy resin to the damaged area and then letting it dry and harden. Epoxy is known for its strength and durability, which makes it an ideal solution for areas that experience heavy traffic or other forms of wear and tear.

Additionally, epoxy can be colored or textured to match the surrounding surface, giving it a seamless appearance. While the epoxy method can be effective, it is also important to note that it can be a complicated process that requires precision and attention to detail. If not applied correctly, epoxy can create uneven surfaces or fail to bond properly, resulting in further damage.

Therefore, it is recommended to hire a professional contractor who is experienced in applying epoxy and can ensure a successful repair.

Final Steps

Now that you have successfully patched up the hole in your oil pan, it’s time to make sure everything is secure. Firstly, give the sealant enough time to dry completely. It is recommended to wait at least 24 hours before driving your vehicle.

Once the sealant has solidified, make sure to clean the area around the patch with a good degreaser. This will help prevent any dirt or grime from getting into the engine. Next, fill up the oil pan with oil until it reaches the appropriate level.

Finally, start up the engine and listen for any strange noises or leaks. If everything sounds normal and there are no leaks, then you’re good to go! However, if there are any issues, it’s best to take your vehicle to a mechanic to get it looked at. Remember, it’s always better to be safe than sorry.

When it comes to fixing a hole in an oil pan, it’s important to take the time to do it right, so you can avoid any further problems down the line. So, take a deep breath, give yourself a pat on the back, and hit the road with confidence knowing that your oil pan is no longer a problem.

Filling the Oil Pan with New Oil

Congratulations! You’re almost finished changing your car’s oil! Now that you have removed the old oil and oil filter, it’s time to refill your oil pan with new oil. Before you do anything else, make sure you have put the drain plug back in its place to avoid any messy spills. Once you’ve double-checked this, locate your car’s oil cap, which is usually located on the engine block and labeled “oil.

” Remove the cap and use a funnel to pour the oil into the oil filler hole. Make sure that you pour in the correct amount of oil. Your vehicle owner’s manual will have the information you need, but most cars take around 5 quarts of oil.

It’s important not to overfill or underfill the oil. Overfilling the oil can cause damage to your engine, while underfilling can result in poor lubrication and corrosion. Avoid adding more oil than the specified amount.

After adding the oil, replace the oil cap. Tighten it by turning it clockwise until it is snug. Start your engine, and let it run for a few minutes to let the oil circulate throughout the engine.

Check your oil levels using the dipstick and add more oil if necessary. Once you are satisfied that you have added the correct amount of oil, turn off your engine, and close your hood. Now, you’re ready to hit the road with fresh oil in your engine! Remember, regular oil changes will help keep your car running smoothly and extend its lifespan.

Checking for Leaks

Checking for leaks is a critical final step in any plumbing project. Once everything is installed, it’s important to take the time to check for any potential leaks before turning on the water. The last thing you want is to have a small leak turn into a big problem down the road.

To begin, make sure the main supply valve is open and slowly turn on the water. Check all visible pipes and connections for any signs of moisture or dripping water. It’s also a good idea to listen for any unusual sounds, such as hissing or rattling, which could indicate a leak.

Don’t forget to check under sinks, around toilets, and behind appliances as well. If you do notice a leak, turn off the water immediately and address the issue before proceeding. By taking the time to check for leaks, you can ensure that your plumbing project is completed successfully and will stand the test of time.

Preventative Measures

If you notice a hole in your oil pan, fixing it should be a top priority. Not only can it lead to oil leaking out, but it can also cause serious damage to your engine. While there are several ways to fix a hole in an oil pan, it’s important to take preventative measures to avoid this issue altogether.

Regularly checking your oil levels and changing the oil and oil filter on schedule is crucial. It’s also important to avoid driving over sharp objects or hitting speed bumps or potholes too hard. By taking these simple steps, you can prevent a hole from forming in your oil pan and avoid costly repairs down the road.

However, if you do find yourself with a hole in your oil pan, it’s best to bring your vehicle to a trusted mechanic who can properly fix the issue.

Conclusion

Fixing a hole in an oil pan isn’t rocket science, but it sure can feel like it if you don’t know where to start. However, fear not, dear reader, for the solution is simpler than you might think. Step one: locate the hole.

Step two: clean the area surrounding the hole with a degreaser or some good old-fashioned elbow grease. Step three: apply a specialized epoxy like J-B Weld or QuikSteel to the affected area. Step four: sit back, relax, and revel in the glory of your newly patched oil pan.

So remember, the next time you find a hole in your oil pan, just follow these steps and you’ll be back on the road in no time. It’s a quick fix for a sticky situation, and the perfect excuse to flex your DIY muscles. Happy repairing!”

FAQs

What causes a hole in an oil pan?

A hole in an oil pan can be caused by road debris or a high impact collision with an object.

Can a hole in an oil pan be patched?

Yes, a hole in an oil pan can be patched by using an epoxy or welding.

How much does it cost to fix a hole in an oil pan?

The cost to fix a hole in an oil pan can vary depending on the severity of the damage, but typically ranges from $200 to $500.

Is it safe to drive with a hole in an oil pan?

No, it is not safe to drive with a hole in an oil pan as it can cause oil to leak out and lead to engine damage. It’s important to get the hole fixed as soon as possible.