Get the Inside Scoop: Learn How to Check Oil Pressure with a Scan Tool Like a Pro!

Have you noticed a decrease in your car’s performance? Maybe you’ve seen the oil pressure warning light come on, or you’re curious about the health of your engine. Whatever the reason, it’s important to know how to check oil pressure with a scan tool. With the help of modern technology, you can gather accurate readings on your vehicle’s oil pressure levels, which is crucial for keeping your engine running smoothly.

In this blog, we’ll go over the steps to use a scan tool to check oil pressure, so you can keep your car in top condition and avoid costly repairs in the future.

Is oil pressure failure a common issue in vehicles?

Oil pressure failure is not a common issue in vehicles that I would personally worry about. Throughout my experience, I have never known of a car to have a catastrophic oil pressure failure. While it is possible for something to pierce an oil pan, this is highly unlikely unless the vehicle is engaged in off-roading activities. In such cases, the main concern typically arises from the pressure sender, which occasionally gives false warnings that can be alarming but are ultimately inconsequential. Therefore, based on my knowledge and encounters, oil pressure failure is not a prevalent concern when it comes to vehicles.

Reasons to Check Oil Pressure

As a responsible car owner, checking the oil pressure is an important task that you shouldn’t take for granted. This is because the oil pressure in your engine is like its lifeblood: it lubricates the engine parts and ensures they work smoothly and efficiently. If the oil pressure is too low, your engine could suffer from damage or fail, leaving you with costly repairs or a ruined vehicle.

So how can you check your oil pressure? One of the easiest ways is to use a scan tool. By simply plugging the tool into your car’s OBD port and following the instructions, you can get a clear reading of your oil pressure levels and take the necessary actions to keep your vehicle in optimal condition. Just make sure to use the right scan tool and follow the recommended procedures to ensure accurate results.

So don’t neglect your oil pressure checks – it could save you a lot of trouble down the road!

Is it recommended to use an OBD reader to read oil pressure while driving?

Using an OBD reader to read oil pressure while driving is not recommended for several reasons. Firstly, OBD readers with live data features are not designed to be read while driving, and attempting to do so can be just as dangerous as reading text messages. Moreover, OBD readers typically use classic LCD displays that are often harder to read, further increasing the risk of distracted driving.

It is important to note that most modern vehicles are equipped with “idiot lights” or driver’s information panels that indicate any potential issues well before any damage is done. These warnings are most effective if the driver pays attention to them and pulls over if necessary. Automotive engineers conscientiously design these systems to ensure that they provide timely alerts to prevent any major damage to the vehicle.

In the case of oil pressure, catastrophic failures are rare, and most vehicles rely on warning lights rather than gauges. Many car owners have reported not experiencing any severe oil pressure failures, even without a gauge. Occasionally, vehicles might provide a “Low Oil Level” warning, which can be triggered, for example, by burning oil in the engine or during intense cornering.

Ultimately, automotive engineers prioritize driver safety and the preservation of their vehicles. They design warning systems to provide timely alerts, ensuring that drivers have sufficient time to respond appropriately. If, however, you feel that having an oil pressure gauge is essential, there may be recommendations from experts or fellow enthusiasts that can guide you towards suitable options.

Importance of Checking Oil Pressure Regularly

Checking oil pressure regularly is an essential part of vehicle maintenance, yet it’s often overlooked until something goes wrong. The oil pressure ensures that there is sufficient oil flow and lubrication to keep the engine running smoothly. Low oil pressure can cause serious damage to your engine and result in costly repairs or even engine failure.

This is why it’s crucial to check oil pressure regularly, especially before embarking on long trips or towing heavy loads. Think of oil pressure like a blood pressure test for your engine – it gives you a good idea of what’s going on under the hood and can alert you to any potential issues before they become major problems. Don’t wait until it’s too late – make oil pressure checks a regular part of your vehicle maintenance routine.

How Scan Tool Can Help with Checking Oil Pressure

As a vehicle owner, it’s essential to regularly check your car’s oil pressure to ensure that everything is working correctly under the hood. Low oil pressure can cause extensive engine damage and even lead to a total breakdown of your car. But, manually checking oil pressure can be challenging and time-consuming.

That’s why a scan tool can be incredibly helpful in taking the guesswork out of the equation. It can provide accurate and real-time data about your car’s oil pressure, enabling you to take immediate action if necessary. Scan tools are an excellent investment that can save you time and money in the long run, preventing any significant problems from occurring and keeping your vehicle running smoothly.

So, if you’re looking for an easy and efficient way to check your car’s oil pressure, investing in a scan tool could be the solution you need.

Preparation: Steps to Take Before Checking Oil Pressure

Before diving into how to check oil pressure with a scan tool, it is important to take a few steps to prep your vehicle. First, make sure your engine is cool and not hot to the touch. Then, locate your vehicle’s oil filter and drain plug and ensure they are both firmly secured.

Next, check your oil level and ensure it is at the appropriate level. An incorrect oil level can lead to faulty readings when checking your oil pressure. Finally, consult your vehicle’s owner manual for any specific instructions or warnings regarding checking oil pressure.

By properly preparing your vehicle, you can ensure accurate readings and prevent any potential damage or accidents. Once you have completed these prep steps, you can move on to the process of checking oil pressure with a scan tool.

Locate and Access the OBD-II Port

When it comes to checking your car’s oil pressure, the first step is to locate and access the OBD-II port. This port is typically located beneath the dashboard on the driver’s side and may be covered by a plastic panel. Before you begin, make sure your car’s engine is turned off and the keys are removed from the ignition.

Then, remove the panel to access the port. It’s important to note that not all cars have the same location for the OBD-II port, so be sure to consult your owner’s manual if you’re having trouble finding it. Once you’ve successfully located the port, it’s time to connect your OBD-II scanner and start extracting data.

By taking these simple steps, you’ll be well on your way to checking your car’s oil pressure and ensuring that everything is working as it should.

Connect the Scan Tool to the OBD-II Port

When preparing to check oil pressure, one important step is connecting the scan tool to the OBD-II port. This port, which can usually be found near the steering wheel of your vehicle, is where the scan tool plugs in to access important information about your car’s systems. Connecting the tool is a simple process that involves finding the port, which may be covered by a small door, and plugging the tool into it.

Once connected, the scan tool will communicate with your car’s engine control module to gather data about the oil pressure. It’s important to make sure the vehicle is turned off and the key is not in the ignition when connecting the scan tool. Additionally, some scan tools require additional setup steps, such as selecting the vehicle make and model and connecting to a Wi-Fi network, so be sure to consult the tool’s instruction manual for specific guidelines.

By properly connecting the scan tool, you can gather important data about your car’s oil pressure and take steps to maintain the health of your engine.

Turn on the Ignition and Scan Tool

Before checking the oil pressure on your vehicle, it’s important to ensure that you’ve properly prepared by following a few vital steps. The first step is to turn on the ignition and let the engine run for a few minutes. This is to get the oil circulating throughout the engine and ensure that you get an accurate reading.

Once the engine has been running for a bit, it’s time to connect the scan tool to the vehicle’s onboard computer system. The scan tool will read the various sensors and provide you with important information such as oil pressure, engine RPM, and more. It’s essential to have a reliable and up-to-date scan tool for accurate readings, so make sure that yours is in good working condition.

By following these necessary preparations, you’ll be able to check your vehicle’s oil pressure with confidence and ensure that your vehicle is running optimally.Keyword: oil pressure, scan tool, preparation, engine, sensors, accurate readings.

Checking Oil Pressure with a Scan Tool

If you’re wondering how to check oil pressure with a scan tool, the process is not as complicated as it may seem. Once you’ve connected your scan tool to your car’s OBD-II port, you can access a number of valuable features, including the ability to check your oil pressure. A good scan tool will give you a detailed readout of your current oil pressure, allowing you to monitor it in real-time.

This can be particularly useful if you’re concerned about the health of your engine or if you’re trying to troubleshoot an issue related to your oil pressure. Plus, using a scan tool is often faster and more accurate than other methods of checking oil pressure, like using a manual gauge. So if you’re looking for a quick and easy way to monitor your oil pressure, a scan tool is definitely worth considering.

Select the Oil Pressure Reading on the Scan Tool Menu

When you suspect that your vehicle’s oil pressure is low, the first thing you should do is check the oil pressure reading on your scan tool menu. This will allow you to confirm whether there’s an actual pressure problem with your engine oil or something else is causing the issue. To select the oil pressure reading on your scan tool, you’ll need to navigate through the various options until you find the relevant indicator.

Once you’ve selected it, you’ll be able to see your oil pressure levels displayed on the screen. Keep in mind that low oil pressure can cause severe damage to your engine in the long term, so it’s important to address the issue as soon as possible if there’s indeed a problem. By using a scan tool, you can easily identify the issue and take the necessary steps to rectify it – be it changing the oil, replacing the oil pump, or fixing any other underlying issues.

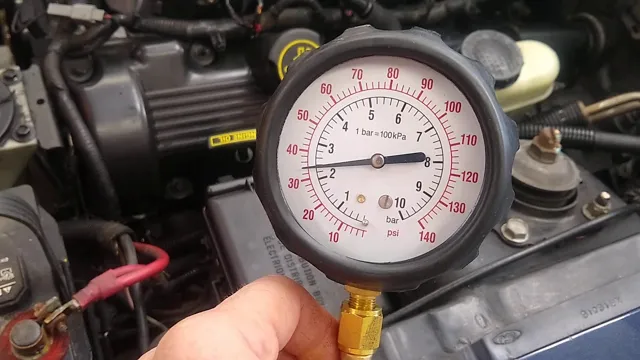

Reading the Oil Pressure Results on the Scan Tool

“If you’re experiencing issues with oil pressure, it’s always a good idea to check it with a scan tool. The process is relatively simple and can save you a lot of trouble down the road. First off, you’ll want to locate the oil pressure sensor. This will vary depending on your vehicle, so refer to the owner’s manual if you’re unsure.

Once you’ve located the sensor, plug in the scan tool and turn the vehicle on. Navigate to the oil pressure section on the scan tool and take note of the readings. This step is crucial in determining the health of your engine.

If the readings are within the normal range, typically indicated by a stable and consistent pressure, you can proceed with confidence. However, if the readings display excessively high or low oil pressure, it’s imperative to consult a mechanic for further diagnosis. Ignoring abnormal oil pressure readings can lead to severe engine damage or failure, resulting in costly repairs.

While using a scan tool to monitor oil pressure is a helpful practice, it’s essential to understand the significance of oil level and oil pressure warnings. An oil level warning is designed to alert you before any damage occurs, giving you time to refill the oil. While less common, it’s advisable to check your vehicle’s owner’s manual to determine if it has this feature.

On the other hand, an oil pressure warning signifies that damage is already taking place in the engine. In such a situation, it is crucial to take immediate action to prevent further harm. Pulling over and stopping the engine is of utmost importance, even if it means finding a safe spot before doing so. Waiting until the next gas station or store could exacerbate the damage and lead to costly repairs or engine replacement.

If you encounter an oil pressure warning, it’s recommended to call for assistance to bring you more oil, or if feasible, walk to obtain more oil. Ignoring an oil pressure warning can have severe consequences, potentially causing irreparable damage to your engine.

In conclusion, while using a scan tool to check oil pressure is a valuable practice, understanding the significance of oil level and oil pressure warnings is equally important. By being vigilant and taking prompt action in response to these warnings, you can safeguard your vehicle’s engine and potentially prevent costly repairs in the future.”<

Compare Readings

Compare the oil pressure reading on the scan tool with the manufacturer’s recommended values for your specific vehicle. Normal oil pressure ranges can vary between different makes and models.

Keep in mind that not all vehicles provide real-time oil pressure data through the OBD-II system. Some vehicles may have a dedicated oil pressure gauge on the instrument cluster, or you may need to use a mechanical oil pressure gauge directly connected to the engine.

Always refer to your vehicle’s service manual for specific instructions and specifications related to oil pressure monitoring. If you’re uncertain or uncomfortable with the process, it’s advisable to seek professional assistance.

Conclusion:

In the quest for optimal engine performance and longevity, checking your oil pressure is an essential step. And what better way to do it than with a scan tool – the technologically advanced equivalent of putting your ear to the engine and hoping for the best. With a scan tool, you’ll be able to get a precise reading of your oil pressure and identify any potential issues before they become costly problems.

So next time you’re under the hood, don’t sweat it – just plug in your scan tool, and let technology do the heavy lifting.”

FAQs

What is a scan tool and how does it work to check oil pressure?

A scan tool is an electronic device that is used to communicate with a vehicle’s onboard computer system. It can be used to perform diagnostics and retrieve vehicle data, including oil pressure readings. To check oil pressure with a scan tool, the tool is connected to the vehicle’s diagnostic port, and the oil pressure sensor data is accessed and displayed on the tool’s screen.

Can a scan tool be used to diagnose low oil pressure in a vehicle?

Yes, a scan tool can be used to diagnose low oil pressure. By accessing the data from the oil pressure sensor, the tool can show the current oil pressure reading, allowing the mechanic to determine if the pressure is too low.

What are the benefits of using a scan tool to check oil pressure?

Using a scan tool to check oil pressure can be very efficient and accurate. The tool provides real-time data, making it easier to diagnose issues and make repairs quickly. It can also save time and money by preventing unnecessary repairs or part replacements.

Are there any considerations when using a scan tool to check oil pressure?

Yes, there are a few things to keep in mind when using a scan tool to check oil pressure. First, the tool should be compatible with the vehicle’s computer system and have the capability to access oil pressure sensor data. Second, the oil pressure sensor must be functioning properly, or an accurate reading cannot be obtained. Finally, the tool should be used by a trained mechanic or technician to ensure proper use and interpretation of the data.