7.3 Powerstroke Turbo Specifications: Boost Your Engine’s Performance

Featured image for this comprehensive guide about 7.3 Powerstroke turbo specifications

Image source: freepnglogos.com

Get ready, 7.3 Powerstroke enthusiasts! You’ve landed here because you understand that the heart of your legendary diesel truck isn’t just its robust engine, but the powerful turbocharger bolted to it. The 7.3L Powerstroke is celebrated for its durability and raw torque, a reputation significantly built on the back of its well-engineered turbo system. But what exactly makes this turbo tick? What are the precise specifications that unleash its formidable power?

Understanding the 7.3 Powerstroke turbo specifications isn’t just for mechanics; it’s for every owner who wants to maximize their truck’s potential, diagnose issues, or consider performance upgrades. Whether you’re towing heavy loads, cruising down the highway, or simply appreciate the mechanical marvel under your hood, knowing the ins and outs of your turbocharger is key. This comprehensive guide will dive deep into the world of the 7.3 Powerstroke turbo, from its stock configurations to common issues and the most effective upgrade paths, helping you boost your engine’s performance and ensure its longevity.

Prepare to unravel the mysteries of boost pressure, A/R ratios, compressor wheels, and turbine housing designs. We’ll equip you with the knowledge to make informed decisions about your truck’s performance, maintenance, and future modifications. Let’s supercharge your understanding of the iconic 7.3 Powerstroke turbo specifications!

Quick Answers to Common Questions

What’s the stock turbo on a 7.3 Powerstroke?

Your 7.3 Powerstroke originally rolled off the line with a Garrett TP38 turbocharger. Understanding these baseline 7.3 Powerstroke turbo specifications is crucial for any future upgrades.

Why would I consider upgrading my 7.3 Powerstroke turbo?

Upgrading your 7.3 Powerstroke turbo specifications can unlock significant gains in horsepower, torque, and even improve towing performance. It’s all about getting more air for more power!

What are some popular upgrade options for the 7.3 Powerstroke turbo?

Many owners go for a “Wicked Wheel 2” compressor upgrade for better spooling or opt for a larger Garrett GTP38R ball-bearing turbo. These enhanced 7.3 Powerstroke turbo specifications offer substantial improvements.

What kind of boost should a healthy 7.3 Powerstroke turbo produce?

A stock 7.3 Powerstroke turbo typically operates in the 18-22 PSI range. Knowing these 7.3 Powerstroke turbo specifications helps you identify if your system is performing as expected.

Will upgrading my 7.3 Powerstroke turbo affect my EGTs (Exhaust Gas Temperatures)?

Yes, improved 7.3 Powerstroke turbo specifications, particularly a more efficient upgrade, can help lower EGTs by moving more air through the engine. This is great for engine longevity, especially when towing heavy loads.

📋 Table of Contents

- The Indomitable Garrett GTP38: Stock 7.3 Powerstroke Turbo Specifications Unveiled

- Evolution and Variations: OBS vs. Super Duty 7.3L Turbo Differences

- Common Turbo-Related Issues and Troubleshooting for the 7.3L

- 7.3 Powerstroke Turbo Upgrades: Unleashing More Power

- Maintenance Tips for Your 7.3L Powerstroke Turbo

- Data Table: Key Stock 7.3 Powerstroke Turbo Specifications (GTP38, 1999.5-2003)

- Conclusion: Mastering Your 7.3 Powerstroke Turbo

The Indomitable Garrett GTP38: Stock 7.3 Powerstroke Turbo Specifications Unveiled

At the core of every factory 7.3 Powerstroke engine, from 1999.5 to 2003 (and slightly different variants for earlier models), sits the venerable Garrett GTP38 turbocharger. This isn’t just any turbo; it’s a workhorse designed for reliability and ample power delivery in a heavy-duty pickup. Understanding its original design and 7.3 Powerstroke turbo specifications is the foundation for any discussion about performance or maintenance.

Learn more about 7.3 Powerstroke turbo specifications – 7.3 Powerstroke Turbo Specifications: Boost Your Engine’s Performance

Image source: nli-research.co.jp

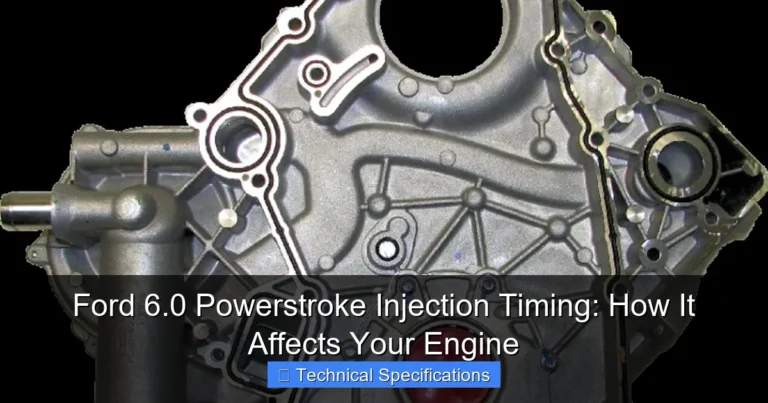

The GTP38 is a journal-bearing turbo, meaning its shaft rides on a film of oil, a design known for its robustness and relatively low cost. While some modern turbos opt for ball bearings for faster spooling, the journal-bearing design proved exceptionally durable in the 7.3L application. Let’s break down the key factory specifications:

| Specification | Value / Detail | Notes / Application |

|---|---|---|

| Turbocharger Model | Garrett GTP38 | Original Equipment Manufacturer (OEM) |

| Compressor Wheel Inducer | 59.8 mm (approx. 2.35 in) | Determines airflow into the engine |

| Turbine Wheel Exducer | 76.5 mm (approx. 3.01 in) | Influences exhaust flow and spool characteristics |

| Turbine Housing A/R Ratio | 1.15 A/R | Common for late 99-03 models; affects spool-up and top-end flow |

| Max Stock Boost Pressure | 18-22 PSI | Dependent on engine load, RPM, and tune |

| Supported Horsepower (Stock) | Up to ~350-400 HP (flywheel) | With minor supporting modifications and tuning |

Compressor Wheel Specifications

The compressor wheel is responsible for drawing in ambient air, compressing it, and forcing it into the engine’s intake manifold. For the 7.3L, the stock compressor wheel strikes a balance between rapid spool-up and decent airflow for stock power levels.

- Inducer Diameter: Approximately 60mm (2.36 inches)

- Exducer Diameter: Approximately 80mm (3.15 inches)

- Material: Cast aluminum

- Number of Blades: Typically 7+7 (split blades, often referred to as a “batmow” wheel for its unique design)

The inducer is the entry point where air enters the compressor wheel, and the exducer is where it exits after compression. A larger exducer generally allows for more airflow at higher RPMs, while the inducer size influences spool characteristics. These 7.3 Powerstroke turbo specifications mean the stock unit is designed for broad usability.

Turbine Wheel Specifications

On the “hot side” of the turbo, the turbine wheel is driven by exhaust gases, which in turn spins the compressor wheel. Its design is crucial for exhaust gas flow and back pressure.

- Inducer Diameter: Approximately 76mm (2.99 inches)

- Exducer Diameter: Approximately 68mm (2.68 inches)

- Material: Inconel (a high-nickel alloy, excellent for high-temperature applications)

- Number of Blades: Typically 10 or 12 blades, depending on the specific model year/revision.

The turbine inducer is where exhaust gases enter, and the exducer is where they exit into the downpipe. The balance between the compressor and turbine wheel sizes is critical for efficient operation and preventing excessive back pressure, which can hinder engine performance and fuel economy.

A/R Ratio: Understanding Turbo Housing Design

The A/R ratio (Area/Radius) is a critical 7.3 Powerstroke turbo specification for both the compressor and turbine housings. It describes the geometric relationship of the housing and significantly impacts how the turbo performs.

- Turbine Housing A/R: The stock GTP38 typically features a 1.15 A/R ratio.

- A smaller A/R ratio (e.g., 0.84) means the exhaust gases hit the turbine wheel at a steeper angle, causing it to spool faster at lower RPMs but potentially leading to higher back pressure at higher RPMs.

- A larger A/R ratio (e.g., 1.15 or 1.30) delays spool-up slightly but allows for better top-end performance and lower back pressure. The 1.15 A/R for the 7.3L offers a good compromise for its intended use.

- Compressor Housing A/R: This is generally fixed and optimized by Garrett for the specific compressor wheel, less commonly modified than the turbine A/R for these stock applications.

These initial 7.3 Powerstroke turbo specifications lay the groundwork for understanding how your truck delivers power and what areas might be improved through upgrades.

Evolution and Variations: OBS vs. Super Duty 7.3L Turbo Differences

While the Garrett GTP38 is the standard turbo for most 7.3 Powerstroke engines from 1999.5-2003, it’s important to acknowledge slight variations, particularly between the earlier OBS (Old Body Style, 1994-1997) and the later Super Duty (1999-2003) models. These distinctions in 7.3 Powerstroke turbo specifications can impact performance and parts compatibility.

Learn more about 7.3 Powerstroke turbo specifications – 7.3 Powerstroke Turbo Specifications: Boost Your Engine’s Performance

Image source: cdn.pixabay.com

Early OBS (1994-1997) Turbo

The OBS models utilized a slightly different turbocharger, often referred to as the “Garrett TP38.” While functionally similar, there are key differences:

- Bearing Design: Still a journal-bearing turbo.

- Compressor Wheel: Typically a 59mm inducer, 80mm exducer, 8-blade cast wheel. This is slightly smaller than the later GTP38 compressor, contributing to a quicker spool but less ultimate airflow.

- Turbine Wheel: Often a 76mm inducer, 68mm exducer, 10-blade Inconel wheel.

- Turbine Housing A/R: Generally a 1.0 A/R for these models. This smaller A/R further aids in faster spool-up, which was desired for the earlier, lower-horsepower applications.

- Wastegate: The early TP38 turbos did not feature an externally controlled wastegate. Instead, they relied on internal exhaust gas flow control or the engine’s design to manage boost.

The TP38 found on the OBS 7.3 Powerstroke was robust for its time but limited in its airflow capacity compared to its successor. Owners of OBS trucks often look to upgrade to a GTP38 or aftermarket turbos to unlock more power.

Late Super Duty (1999.5-2003) GTP38 Turbo

The Super Duty era brought several refinements, including the introduction of the intercooler and the more advanced Garrett GTP38. The 7.3 Powerstroke turbo specifications for this model are what most enthusiasts refer to when discussing the stock turbo.

- Compressor Wheel: As detailed earlier, a 60mm inducer, 80mm exducer, 7+7 blade cast wheel. This slightly larger design allows for more airflow.

- Turbine Housing A/R: A 1.15 A/R ratio for improved top-end flow, complementing the intercooler and higher factory horsepower ratings.

- Wastegate: A crucial addition was the vacuum-actuated wastegate (controlled by the Powertrain Control Module or PCM) on the exhaust housing. This external wastegate allows the PCM to precisely control boost pressure, preventing over-boosting and optimizing performance across the RPM range. This is a significant distinction in 7.3 Powerstroke turbo specifications compared to the OBS.

- EBPV (Exhaust Back Pressure Valve): The Super Duty GTP38 also incorporates an Exhaust Back Pressure Valve. This valve closes to create back pressure, primarily to aid in engine warm-up during cold weather. While beneficial for emissions and cold starts, a stuck-closed EBPV can significantly restrict exhaust flow and hurt performance, mimicking a turbo issue.

Understanding these subtle yet important differences is crucial when sourcing replacement parts, planning upgrades, or diagnosing issues. Always specify your exact model year when discussing 7.3 Powerstroke turbo specifications with suppliers or mechanics.

Common Turbo-Related Issues and Troubleshooting for the 7.3L

Even with its reputation for durability, the 7.3 Powerstroke turbo isn’t immune to problems. Recognizing common symptoms and knowing how to troubleshoot them can save you time, money, and frustration. Many issues stem from simple wear and tear or neglected maintenance.

1. Boost Leaks

- Symptoms: Low boost, loss of power, excessive black smoke, whistling or hissing sounds under load, increased Exhaust Gas Temperatures (EGTs).

- Common Causes: Cracked intercooler pipes, worn or blown boots (silicone couplers), loose clamps, leaks in the intercooler itself.

- Troubleshooting: Visually inspect all boots and pipes. A “boost leak test kit” (which pressurizes the intake system with shop air) is the most effective way to pinpoint leaks. Listen for hissing and spray soapy water on suspected areas to watch for bubbles.

2. Worn Turbo Bearings / Shaft Play

- Symptoms: Excessive shaft play (side-to-side or in-and-out), grinding noises from the turbo, oil consumption (oil leaking past seals), blue smoke from the exhaust, turbo “screaming” or “whining.”

- Common Causes: Lack of proper lubrication (infrequent oil changes, low oil pressure), contamination in the oil, extreme heat cycling, age.

- Troubleshooting: Remove the intake boot and exhaust downpipe. With the engine off, check for shaft play. There should be minimal side-to-side play and virtually no in-and-out play. Any significant movement usually indicates worn bearings and requires turbo replacement or rebuild.

3. Wastegate Problems (1999.5-2003 Models)

- Symptoms:

- Stuck Open: Low boost, lack of power.

- Stuck Closed: Over-boosting, potential engine damage, surging.

- Diaphragm Rupture: No wastegate operation, resulting in over-boosting or surging.

- Common Causes: Corroded wastegate actuator rod, ruptured vacuum diaphragm, faulty vacuum lines, issues with the Electronic Pressure Regulator (EPR) valve (which controls vacuum).

- Troubleshooting: Check the vacuum line to the actuator. Apply vacuum manually to the actuator to see if the rod moves freely. Check for tears in the diaphragm. Scan for diagnostic trouble codes (DTCs) related to boost control.

4. EBPV (Exhaust Back Pressure Valve) Issues (1999.5-2003 Models)

- Symptoms: Reduced power, high EGTs, excessive back pressure, turbo surge, loud “moaning” or “whistling” noise. The valve might stay partially or fully closed when it shouldn’t.

- Common Causes: Carbon buildup in the EBPV housing, faulty EBPV actuator, wiring issues, corrosion.

- Troubleshooting: Visually inspect the EBPV for carbon buildup. Check the wiring to the actuator and ensure it moves freely. Many owners opt to remove or disable the EBPV if they don’t experience extremely cold weather starts, as it can be a source of problems and performance restriction.

5. Turbo Surge

- Symptoms: A fluttering or chattering noise from the turbo during acceleration, especially under heavy load or at specific RPMs. This is the turbo’s compressor fighting against itself due to insufficient airflow into the engine.

- Common Causes: Too large of a turbo for the engine’s fueling, boost leaks, improper tuning, restricted intake. Sometimes, it can be triggered by a faulty EBPV or wastegate.

- Troubleshooting: Address any potential boost leaks or EBPV issues first. If aftermarket tuning or a larger turbo is installed, tuning adjustments may be necessary.

Regular maintenance and attentive driving habits are your best defense against these common issues. Understanding these potential problems associated with your 7.3 Powerstroke turbo specifications will enable you to keep your truck running smoothly.

7.3 Powerstroke Turbo Upgrades: Unleashing More Power

While the stock Garrett GTP38 is a robust unit, many 7.3 Powerstroke owners eventually seek to upgrade their turbo for more power, better towing characteristics, or simply to improve reliability after years of service. There’s a wide range of options, from mild enhancements to complete turbo system overhauls. Keep in mind that turbo upgrades often require supporting modifications like larger injectors, custom tuning, and improved exhaust flow.

1. Mild Upgrades: Improving Stock Performance

- Wicked Wheel 2 (WW2): This is perhaps the most popular and cost-effective upgrade for the stock GTP38. The WW2 is an aftermarket compressor wheel with a more aggressive blade design (typically 6+6 or 7+7 blades) that replaces the stock cast wheel.

- Benefits: Reduces compressor surge, increases boost pressure slightly, provides a quicker and smoother spool-up, and can offer a small bump in power (5-15 HP). It’s a direct drop-in replacement.

- Limitations: Still constrained by the overall size of the stock turbo housings.

- Larger Compressor Housing: Some aftermarket companies offer a larger compressor housing for the GTP38, allowing for the use of a slightly larger compressor wheel (e.g., 63mm inducer).

- Benefits: More airflow potential than just a WW2, less restrictive, can support more fuel.

- Limitations: Requires removing the turbo and disassembling the compressor side.

- High-Flow Exhaust Outlet/Downpipe: Reducing back pressure immediately downstream of the turbine can improve turbo efficiency and spool-up. A larger, less restrictive downpipe is a common first modification.

2. Hybrid Turbos: The Best of Both Worlds

Hybrid turbos combine elements of the stock GTP38 with larger, more efficient components. They typically utilize the stock GTP38 center section but feature a larger compressor wheel, often a larger turbine wheel, and sometimes a modified compressor housing. These typically require a full removal and reinstallation.

- Examples: Many manufacturers offer their versions, often branded as “GTP38R” (though not always a true Garrett ball-bearing unit) or similar. These might feature a 63mm inducer compressor wheel and sometimes a larger 1.0 A/R turbine housing for better flow.

- Benefits: Significantly increased airflow capacity compared to stock, quicker spool than much larger non-stock turbos, excellent for towing and performance street driving. Can support moderate to large injector upgrades.

- Considerations: More expensive than mild upgrades. Requires custom tuning and often upgraded fuel system components (injectors, fuel pump).

3. Larger Frame Turbos: Maximum Performance

For those seeking substantial power gains, a complete replacement of the Garrett GTP38 with a larger, more efficient turbocharger is the ultimate path. These often come in the form of S300 or S400 frame turbos (e.g., BorgWarner S363, S366, S467.7). These are not bolt-on replacements and require significant modifications.

- Mounting: Typically require custom T4 turbo mounting kits, which relocate the turbo to a different position in the engine bay.

- Benefits: Massive airflow potential, ability to support very large injectors and high horsepower numbers (450 HP+), reduced EGTs, improved efficiency at higher boost levels.

- Considerations:

- Cost: Significantly more expensive (turbo, T4 kit, associated piping).

- Spool-up: Larger turbos generally have a slower spool-up compared to stock or hybrid options, although modern designs minimize this.

- Supporting Mods: Absolutely require large injectors, upgraded fuel system, custom tuning, full exhaust, and often head studs to handle the increased cylinder pressures.

- Driveability: Can impact daily driveability, especially if not properly matched to the engine and driving style.

When considering 7.3 Powerstroke turbo upgrades, always assess your goals: daily driver, tow rig, race truck. Research thoroughly, consult with reputable tuners, and factor in all necessary supporting modifications. Simply bolting on a bigger turbo without adequate fuel and tuning can lead to poor performance or, worse, engine damage.

Maintenance Tips for Your 7.3L Powerstroke Turbo

The longevity of your 7.3 Powerstroke turbo largely depends on consistent, quality maintenance. These turbos are oil-lubricated and air-cooled, making oil quality and air filtration paramount. Adhering to a strict maintenance schedule will ensure your turbo continues to deliver reliable boost for years to come.

1. Regular Oil Changes with Quality Oil

This is arguably the single most important maintenance item for any turbocharger. The oil not only lubricates the journal bearings but also helps cool the turbo. Dirty or degraded oil is the enemy of turbo bearings.

- Recommendation: Follow your owner’s manual for oil change intervals, typically 3,000-5,000 miles for conventional diesel oil, or 7,500-10,000 miles for full synthetic.

- Oil Type: Use a high-quality diesel-rated engine oil (CJ-4 or CK-4 spec for modern oils) of the recommended viscosity (e.g., 15W-40).

- Filter: Always use a premium oil filter that meets or exceeds OEM specifications.

- Actionable Tip: Consider sending oil samples for analysis every few oil changes. This can detect early signs of bearing wear, fuel dilution, or other issues before they become catastrophic.

2. Maintain a Clean Air Intake System

Dust and debris entering the compressor can damage the delicate fins of the compressor wheel, leading to imbalance and premature bearing wear. Restricted airflow can also cause the turbo to work harder, generating more heat.

- Air Filter: Inspect and replace your air filter regularly. For heavy-duty use or dusty environments, more frequent changes are necessary.

- Intake Boots and Pipes: Regularly inspect all intake boots and pipes for cracks, tears, or loose clamps. Even small leaks can allow unfiltered air into the turbo.

- Actionable Tip: If you operate in extremely dusty conditions, consider an aftermarket air intake system known for superior filtration. Ensure you’re not sacrificing filtration for airflow, as this can be detrimental to turbo and engine life.

3. Monitor Boost and EGTs (Exhaust Gas Temperatures)

Gauges are your turbo’s best friends. An aftermarket boost gauge and EGT gauge are highly recommended for any 7.3 Powerstroke owner, especially those with modified trucks.

- Boost Gauge: Helps you monitor if your turbo is building adequate boost and if it’s consistent. Sudden drops or spikes can indicate issues.

- EGT Gauge: High EGTs are detrimental to your turbo’s turbine housing and wheel, as well as engine components. Running too hot can cause premature failure. Use the EGT gauge to monitor and adjust your driving style, especially when towing or under heavy load.

- Actionable Tip: Avoid sustained high EGTs (above 1250°F post-turbo, or 1350°F pre-turbo) by backing off the throttle or downshifting. Allow the engine to cool down for a minute or two at idle after heavy use before shutting it off (turbo timer functionality, if equipped).

4. Inspect for Shaft Play

Periodically (e.g., during major services or if you suspect an issue), physically check for shaft play on the turbocharger.

- Procedure: Remove the intake elbow from the compressor housing. With the engine off, grasp the compressor nut or shaft and attempt to move it side-to-side and in-and-out.

- What to Look For: Minimal side-to-side play is normal (due to the oil film), but there should be virtually no in-and-out (axial) play. Any significant in-and-out play indicates worn thrust bearings and signals impending failure.

5. Keep the EBPV Clean and Functional (if applicable)

For 1999.5-2003 trucks, the EBPV needs attention.

- Cleaning: Carbon buildup can prevent the valve from operating correctly. If accessible, periodically clean the valve and its housing.

- Functionality Check: Ensure the actuator rod moves freely and the valve isn’t stuck. If you live in a warm climate and don’t rely on the EBPV for cold starts, some owners choose to remove or permanently disable it to eliminate a potential failure point and improve exhaust flow.

By diligently following these maintenance tips, you can significantly extend the life of your 7.3 Powerstroke turbo and ensure it continues to deliver the legendary performance you expect from your truck.

Data Table: Key Stock 7.3 Powerstroke Turbo Specifications (GTP38, 1999.5-2003)

For quick reference, here’s a summary of the most important stock 7.3 Powerstroke turbo specifications for the Garrett GTP38 found in 1999.5-2003 Super Duty models. These numbers represent the factory configuration and are your baseline for performance expectations or upgrade considerations.

| Component | Specification | Details / Notes |

|---|---|---|

| Turbocharger Model | Garrett GTP38 | Stock for 1999.5-2003 Super Duty 7.3L Powerstroke |

| Bearing Type | Journal Bearing | Oil-lubricated, known for durability |

| Compressor Wheel Inducer | ~60 mm (2.36 in) | Diameter where air enters the compressor wheel |

| Compressor Wheel Exducer | ~80 mm (3.15 in) | Diameter where compressed air exits the compressor wheel |

| Compressor Wheel Blades | 7+7 Blade (Split Blade) | Commonly referred to as “batmow” style by some for its unique design |

| Turbine Wheel Inducer | ~76 mm (2.99 in) | Diameter where exhaust gas enters the turbine wheel |

| Turbine Wheel Exducer | ~68 mm (2.68 in) | Diameter where exhaust gas exits the turbine wheel |

| Turbine Wheel Blades | 10 or 12 Blade | Varies slightly by model year/revision |

| Turbine Housing A/R Ratio | 1.15 A/R | A balance between quick spool and good top-end flow |

| Wastegate | External, Vacuum Actuated | Controlled by PCM to regulate boost pressure (1999.5-2003 only) |

| EBPV (Exhaust Back Pressure Valve) | Yes | Integrated, aids in cold weather warm-up (1999.5-2003 only) |

| Peak Stock Boost Pressure | ~18-22 PSI | Varies slightly with conditions and specific engine calibration |

This table summarizes the core 7.3 Powerstroke turbo specifications for the most common GTP38 model. Early OBS (TP38) models will have slightly different figures, particularly a smaller compressor inducer, a 1.0 A/R turbine housing, and no wastegate or EBPV.

Conclusion: Mastering Your 7.3 Powerstroke Turbo

Understanding the 7.3 Powerstroke turbo specifications is more than just knowing a few numbers; it’s about gaining a deeper appreciation for the engineering that makes your truck a legend. From the robust Garrett GTP38’s design to its intricate operation and the nuances between OBS and Super Duty models, every detail plays a role in your engine’s performance and longevity. You now have the knowledge to decipher what makes your turbo tick, identify potential issues, and strategize for future upgrades.

Whether your goal is to maintain the legendary reliability of your 7.3L, coax out a little more power for towing, or embark on a full-blown performance build, having a solid grasp of these specifications is your first step. Remember, diligent maintenance, proactive troubleshooting, and informed upgrade choices are key to ensuring your 7.3 Powerstroke turbo continues to boost your engine’s performance for hundreds of thousands of miles to come. Keep those wheels spooling, and enjoy the power and durability that only a 7.3L Powerstroke can deliver!

🎥 Related Video: 7.3 KC Turbo Upgrade!!

📺 Flying Wrenches

Thanks for watching! Want me to work on your truck or car? Here’s my link tree!!! – https://linktr.ee/flyingwrenches Amazon …

Frequently Asked Questions

What are the factory 7.3 Powerstroke turbo specifications?

The factory 7.3 Powerstroke turbo is typically a Garrett TP38 for early models (up to mid-1999) and a Garrett GTP38 for later models (mid-1999 onwards). Both are fixed geometry turbos, with the GTP38 offering slight improvements in design and durability, but sharing similar performance characteristics.

How much boost does a stock 7.3 Powerstroke turbo typically produce?

A healthy, stock 7.3 Powerstroke turbo generally produces between 15-22 PSI of boost under full load, depending on the specific engine calibration and altitude. Monitoring your boost levels is a good indicator of your turbo’s health and engine performance.

What are common upgrade options for the 7.3 Powerstroke turbo?

Common 7.3 Powerstroke turbo upgrades include installing larger compressor wheels (e.g., a “Big Head” or “Wicked Wheel”) to improve airflow and reduce surge, or replacing the entire unit with a larger Garrett GTP38R ball-bearing turbo. Aftermarket performance turbos with different compressor/turbine configurations are also popular for significant power gains.

What are some common issues or failures associated with the 7.3 Powerstroke turbo?

Common issues with the 7.3 Powerstroke turbo include worn bearings leading to shaft play and oil leaks, a cracked exhaust housing (especially on the “hot side” due to heat cycles), and boost leaks from old boots or intercooler pipes. Excessive black or blue smoke, along with reduced power, can often indicate a turbo problem.

Do I need other modifications when upgrading my 7.3 Powerstroke turbo?

Yes, upgrading your 7.3 Powerstroke turbo often necessitates other modifications to fully realize its potential and ensure engine longevity. This typically includes custom engine tuning, upgraded fuel injectors, a higher-flowing air intake, and a less restrictive exhaust system to manage increased airflow and power output.

How does a larger 7.3 Powerstroke turbo affect engine performance and towing?

A larger 7.3 Powerstroke turbo significantly boosts engine performance by increasing airflow, leading to more horsepower and torque, especially at higher RPMs. For towing, this translates to improved pulling capability and lower exhaust gas temperatures (EGTs), though some larger turbos might introduce a bit more turbo lag at very low RPMs.