7.3 Powerstroke Crankcase Pressure Troubleshooting: Solutions for Your Engine

Featured image for this comprehensive guide about 7.3 Powerstroke crankcase pressure troubleshooting

Image source: clipart-library.com

7.3 Powerstroke Crankcase Pressure Troubleshooting: Solutions for Your Engine

The legendary 7.3 Powerstroke engine is a testament to durability and raw power, a workhorse that has earned its reputation among truck enthusiasts and heavy-duty operators alike. Known for its robust design and million-mile potential, even the most bulletproof engines can develop issues over time. One common concern that often puzzles owners is dealing with excessive crankcase pressure, a condition commonly referred to as “blow-by.”

When your trusty 7.3 Powerstroke starts exhibiting signs of high crankcase pressure, it can be a source of worry. It’s not just a minor annoyance; it can indicate underlying problems that, if left unaddressed, could lead to more significant engine damage, costly repairs, and a noticeable drop in performance. This comprehensive guide is designed to empower you with the knowledge and actionable steps needed for effective 7.3 Powerstroke crankcase pressure troubleshooting, helping you diagnose, understand, and resolve these issues to keep your diesel beast running strong for years to come.

Whether you’re experiencing excessive smoke from your oil filler cap, unexplained oil leaks, or a noticeable decrease in engine efficiency, understanding the nuances of your 7.3 Powerstroke’s crankcase ventilation system and the potential causes of blow-by is the first step toward a healthy engine. Let’s dive deep into the world of 7.3 Powerstroke crankcase pressure, providing you with solutions and insights to maintain peak performance.

Quick Answers to Common Questions

What is 7.3 Powerstroke crankcase pressure and why should I care?

It’s the pressure that builds up inside your engine’s crankcase, usually from combustion gases leaking past piston rings. Too much 7.3 Powerstroke crankcase pressure can lead to oil leaks, poor engine performance, and even internal damage, so it’s definitely something to address.

How can I tell if my 7.3 Powerstroke has excessive crankcase pressure?

Common signs include oil leaks (especially around the dipstick or oil fill cap), a “puffing” or smoking oil fill tube when the engine is running, and sometimes a noticeable drop in engine power. Keep an eye out for these clues during your 7.3 Powerstroke crankcase pressure troubleshooting.

What’s the quickest way to check my 7.3 Powerstroke’s crankcase pressure?

A simple visual test involves removing your oil fill cap while the engine is idling; excessive pressure will cause it to dance or even blow off the opening. For a more accurate reading, you can use a manometer connected to the dipstick tube.

What’s a common cause of high 7.3 Powerstroke crankcase pressure?

Worn piston rings are a very common culprit, allowing combustion gases to blow past them and pressurize the crankcase. Issues with your engine’s Crankcase Depression Regulator (CDR) valve, sometimes called a PCV valve, can also contribute significantly to high 7.3 Powerstroke crankcase pressure.

Is a little bit of crankcase pressure normal for a 7.3 Powerstroke?

Yes, a small amount of “blow-by” and slight pressure is normal in any internal combustion engine, especially as it ages. The key is when it becomes excessive, leading to the symptoms we’ve discussed, indicating a need for 7.3 Powerstroke crankcase pressure troubleshooting.

📋 Table of Contents

- Understanding Crankcase Pressure in Your 7.3 Powerstroke

- Common Symptoms of Excessive 7.3 Powerstroke Crankcase Pressure

- Diagnosing the Root Causes of 7.3 Powerstroke Blow-by

- Step-by-Step 7.3 Powerstroke Crankcase Pressure Troubleshooting Guide

- Solutions and Preventative Maintenance for 7.3 Powerstroke Crankcase Pressure

- Conclusion

Understanding Crankcase Pressure in Your 7.3 Powerstroke

To effectively perform 7.3 Powerstroke crankcase pressure troubleshooting, it’s vital to grasp what crankcase pressure is and why it matters for your engine’s health. It’s a fundamental aspect of internal combustion engine operation.

Learn more about 7.3 Powerstroke crankcase pressure troubleshooting – 7.3 Powerstroke Crankcase Pressure Troubleshooting: Solutions for Your Engine

Image source: png.pngtree.com

What is Crankcase Pressure and Blow-by?

In a perfect world, all the combustion gases generated during the power stroke of your engine would remain sealed within the combustion chamber, pushing the piston down with maximum force. However, in reality, a small amount of these high-pressure gases inevitably escapes past the piston rings and into the crankcase. This phenomenon is known as “blow-by.”

| Symptom / Observation | Crankcase Pressure (ICP) Indication | Probable Cause | Recommended Action |

|---|---|---|---|

| Minimal/no smoke from oil fill tube, slight ‘puffing’. Oil cap stable. | 0-1 inch H2O at idle, <4 inches H2O at 2500 RPM | Normal engine operation; healthy combustion seal. | No action required. Monitor regularly as part of routine maintenance. |

| Consistent, light to moderate smoke from oil fill tube. Oil cap ‘dances’ slightly. Minor oil leaks. | 2-5 inches H2O at idle, 5-10+ inches H2O at 2500 RPM | Moderate engine wear (e.g., piston rings, valve guides). Minor turbo seal leak. | Perform compression/leak-down test. Consider engine oil analysis. Inspect turbocharger. |

| Heavy, steady stream of smoke/pressure from oil fill tube. Oil cap visibly “dancing” or easily blown off. Significant oil leaks, loss of power. | >5 inches H2O at idle, >15-20+ inches H2O at 2500 RPM | Severe engine damage (e.g., cracked piston, severely worn rings). Major turbocharger oil seal failure. | Immediately cease engine operation. Perform compression/leak-down test. Inspect turbo and internal engine components. |

| Mild blow-by symptoms, but increased oil leaks around seals (front/rear main, valve covers) or dipstick. | Elevated pressure, potentially inconsistent. Hard to differentiate from engine wear without further checks. | Restricted Crankcase Ventilation (CCV) system. External blockage of breather tube. | Inspect and clear CCV system hoses, connections, and “doghouse” breather tube to ensure proper venting. |

- Crankcase: The lower part of the engine block where the crankshaft rotates and engine oil is stored.

- Piston Rings: These rings on the piston are designed to seal the combustion chamber and scrape oil from the cylinder walls.

- Blow-by: The leakage of combustion gases (a mixture of fuel vapor and exhaust gases) from the combustion chamber past the piston rings and into the crankcase.

A certain amount of blow-by is normal, even in a healthy engine. The amount typically increases as the engine ages and components like piston rings and cylinder walls experience wear. However, excessive blow-by leads to excessive crankcase pressure, which can be detrimental.

Why is Proper Crankcase Ventilation Crucial?

Your 7.3 Powerstroke, like all modern engines, is equipped with a sophisticated crankcase ventilation system designed to manage and evacuate these blow-by gases. On the 7.3 Powerstroke, this system is primarily an open-breather system, often referred to as the CCV (Crankcase Ventilation) system, which vents gases from the valve covers, typically through a “doghouse” filter, to the atmosphere or a catch can setup.

The primary functions of this system are:

- Prevent Pressure Buildup: To release the accumulated pressure from the crankcase. Without proper ventilation, this pressure can build up, pushing against seals and gaskets, leading to oil leaks.

- Remove Contaminants: Blow-by gases contain unburnt fuel vapors and water vapor. If these remain in the crankcase, they can condense into acids and sludge, contaminating the engine oil and accelerating wear.

- Maintain Engine Health: By removing harmful gases and managing pressure, the ventilation system helps maintain the cleanliness and longevity of your engine oil and internal components.

When the ventilation system fails to do its job, or when blow-by becomes excessive, you’ll start noticing the symptoms we’ll discuss next. Understanding this mechanism is the bedrock for effective 7.3 Powerstroke crankcase pressure troubleshooting.

Common Symptoms of Excessive 7.3 Powerstroke Crankcase Pressure

Identifying the signs of high 7.3 Powerstroke crankcase pressure early can save you from more extensive repairs down the line. Keep an eye (and ear) out for these tell-tale indicators.

Learn more about 7.3 Powerstroke crankcase pressure troubleshooting – 7.3 Powerstroke Crankcase Pressure Troubleshooting: Solutions for Your Engine

Image source: cdn.pixabay.com

Visual and Auditory Clues

These are often the first signs you’ll notice that prompt you to investigate further:

- Smoke from Oil Filler Cap or Dipstick Tube: This is the classic and most direct indicator of blow-by. With the engine running (and warm), carefully remove the oil filler cap. If you see a significant amount of white or grayish smoke puffing out, and feel noticeable pressure, it’s a strong sign of excessive crankcase pressure. A slight wisp is normal, but a continuous stream or strong puffing indicates an issue. The same test can be performed by pulling the dipstick.

- Oil Leaks: Elevated crankcase pressure will push past the weakest seals and gaskets in your engine. Common leak points on a 7.3 Powerstroke include:

- Front and rear main seals

- Valve cover gaskets

- High-Pressure Oil Pump (HPOP) cover gasket

- Oil pan gasket

- Turbocharger oil return line seals

You might notice fresh oil puddles under your truck or a generally oil-stained engine bay.

- Whistling or Hissing Noises: Sometimes, excessive pressure can create an audible whistle or hiss as gases escape through small openings or compromised seals.

- Increased Oil Consumption: While not always directly visible as a leak, high blow-by can lead to more oil being pushed into the intake system or burnt off, resulting in you needing to add oil more frequently.

Performance-Related Symptoms

Excessive crankcase pressure doesn’t just make a mess; it can actively degrade your engine’s performance:

- Reduced Power and Acceleration: When combustion gases escape past the piston rings, it means less pressure is being exerted on the piston, directly translating to a loss of horsepower and torque. Your truck might feel sluggish or struggle under load.

- Turbo Lag or Reduced Boost: Blow-by gases can sometimes pressurize the turbocharger’s drain system or interfere with its operation, leading to delayed turbo spool-up or an inability to reach commanded boost levels.

- Increased Fuel Consumption: A less efficient engine, one that’s losing power due to blow-by, will often compensate by using more fuel to achieve the same output.

- Check Engine Light (CEL): While not a direct symptom of blow-by itself, related issues like sensor contamination (MAP, EBP) or turbo performance issues can trigger a CEL.

Recognizing these symptoms is a critical step in your 7.3 Powerstroke crankcase pressure troubleshooting journey. Once you’ve identified these signs, you’re ready to start diagnosing the root cause.

Diagnosing the Root Causes of 7.3 Powerstroke Blow-by

Once you’re confident that your 7.3 Powerstroke is indeed experiencing excessive crankcase pressure, the next step is to pinpoint the exact cause. This often involves a systematic approach, starting with simple tests and progressing to more in-depth diagnostics.

The “Oil Filler Cap Test” Explained

This is the most common and easiest preliminary test for 7.3 Powerstroke blow-by:

- Warm Up the Engine: Ensure the engine is at operating temperature. This allows components to expand and provides a more accurate reading.

- Remove Oil Filler Cap: With the engine idling, carefully remove the oil filler cap.

- Observe and Feel:

- Normal: A slight wisp of vapor, perhaps an intermittent puff, and very little to no pressure pushing the cap up. You should be able to place the cap upside down on the opening and it will sit there relatively undisturbed, maybe gently dancing a bit.

- Excessive: A continuous, strong stream of white/grayish smoke, significant pressure pushing the cap away from the opening, or the cap actively jumping/dancing vigorously.

- Alternatively, the “Glove Test”: Place a nitrile glove over the oil filler neck and secure it. If the glove inflates quickly and dramatically, it indicates significant pressure.

This test provides a quick snapshot but doesn’t tell you *why* the pressure is high.

Inspecting the PCV/Breather System

A restricted or clogged crankcase ventilation system is a common, and often overlooked, cause of increased crankcase pressure. The 7.3 Powerstroke typically uses a “doghouse” filter on the driver’s side valve cover, which can become saturated with oil and sludge over time.

- Check the Doghouse Filter: Remove the “doghouse” assembly from the driver’s side valve cover. Inspect the filter media inside. If it’s heavily saturated with oil or appears clogged, it needs to be cleaned or replaced.

- Inspect Hoses and Tubes: Follow the ventilation hoses from the valve covers. Look for kinks, cracks, blockages (especially from carbon or oil sludge), or disconnections. Ensure clear pathways for blow-by gases to escape.

- Clean the System: If components are dirty but not damaged, a thorough cleaning with a degreaser can restore proper function.

Cylinder Compression & Leak-Down Test

If the breather system is clear, and you still have significant blow-by, the problem likely lies within the engine’s internal components. This is where more advanced diagnostics come into play.

- Compression Test: Measures the maximum pressure each cylinder can build. Low compression in one or more cylinders can indicate worn piston rings, worn cylinder walls, or faulty valves/head gaskets.

- Leak-Down Test: This test is more precise. It involves injecting compressed air into each cylinder with the piston at Top Dead Center (TDC) and measuring how much air leaks out and where it leaks from.

- Air hissing from the oil filler cap/dipstick: Indicates worn piston rings or cylinder walls. This is a direct confirmation of internal engine blow-by.

- Air hissing from the exhaust pipe: Indicates a leaking exhaust valve.

- Air bubbling in the radiator: Indicates a leaking head gasket or cracked head.

- Air hissing from the intake manifold: Indicates a leaking intake valve.

These tests are definitive for internal engine wear and are crucial for determining if an engine rebuild is necessary.

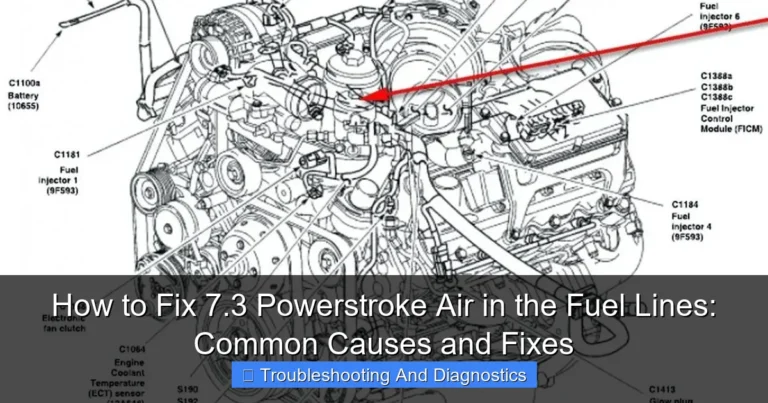

Turbocharger Inspection

The turbocharger on your 7.3 Powerstroke can also contribute to excessive crankcase pressure, specifically if its seals are failing.

- Oil Seals: Worn oil seals within the turbocharger (especially the compressor side) can allow boost pressure to force its way into the oil drain system, which connects to the crankcase. This pressure then contributes to overall crankcase pressure.

- Shaft Play: Grab the turbocharger shaft (after removing the intake pipe) and check for excessive side-to-side or in-and-out play. Significant play suggests worn bearings and seals, which could be the source of your problem.

- Oil in the Intake or Exhaust: Evidence of oil in the intake pipes (compressor side) or heavy blue smoke from the exhaust (turbine side) can also point to failing turbo seals.

Other Potential Culprits

While less common, consider these possibilities during your 7.3 Powerstroke crankcase pressure troubleshooting:

- Vacuum Pump (HVAC pump): Some 7.3 Powerstrokes use a vacuum pump that can, in rare cases, develop a diaphragm leak that pressurizes the crankcase. This is less common but worth considering if all other avenues are exhausted.

- Restricted Exhaust: A severely restricted exhaust system (e.g., a clogged catalytic converter or muffler) can cause back pressure that impacts how the engine breathes and evacuates gases, potentially creating symptoms that mimic blow-by.

Step-by-Step 7.3 Powerstroke Crankcase Pressure Troubleshooting Guide

Let’s consolidate the diagnostic steps into an actionable sequence to help you systematically approach your 7.3 Powerstroke crankcase pressure troubleshooting.

Initial Visual Inspection

- Look for Obvious Leaks: Scan the engine for oil leaks, especially around the valve covers, oil pan, front/rear main seals, and turbocharger connections. Fresh oil stains are a strong indicator of elevated crankcase pressure pushing past seals.

- Check Hoses and Connections: Ensure all hoses related to the crankcase ventilation system (on the valve covers) are connected, intact, and free from cracks, kinks, or disconnections.

- Examine the Engine Bay: Look for any signs of excessive oil mist or residue, especially near the breather filter or valve covers.

Perform the Blow-by Test

- Warm Up Engine: Drive the truck until it reaches normal operating temperature.

- Idle and Observe: Park the truck on a level surface, engage the parking brake, and let the engine idle.

- Oil Filler Cap Test: Carefully remove the oil filler cap.

- Minimal to No Smoke/Pressure: Likely normal.

- Moderate Smoke/Pressure (Cap ‘dances’): Indicates some blow-by, could be normal for an older engine, but warrants further investigation of the breather system.

- Heavy Smoke/Strong Pressure (Cap ‘jumps’ off): Excessive blow-by, requiring immediate attention.

- Dipstick Test: Pull the dipstick slightly out of its tube. Observe for smoke or feel for pressure escaping.

Evaluate the Breather System

- Inspect Doghouse Filter: Remove the “doghouse” breather from the driver’s side valve cover. Inspect the filter element for oil saturation or blockage. Clean or replace if necessary.

- Clear Breather Hoses: Detach and inspect the breather hoses for any internal blockages (sludge, carbon buildup). Clear them using compressed air or a suitable cleaner.

- Ensure Free Flow: Reassemble the breather system and ensure all components allow for unimpeded flow of crankcase gases.

Advanced Diagnostics (If Blow-by Persists)

If cleaning the breather system doesn’t resolve the excessive pressure, the problem is likely internal:

- Compression Test: Perform a compression test on all cylinders. Note any cylinders with significantly lower readings, as this points to internal wear.

- Leak-Down Test: This is highly recommended. Perform a leak-down test, paying close attention to air escaping from the oil filler neck or dipstick tube, which confirms piston ring/cylinder wall wear.

- Turbocharger Inspection:

- Remove the intake boot to the turbo and check for excessive shaft play (side-to-side and in-and-out).

- Look for oil accumulation in the turbocharger’s compressor housing or in the intercooler pipes.

- Check for oil in the exhaust side of the turbo.

- Vacuum Pump Check (Rare): If all else fails, consider checking the vacuum pump for leaks, though this is a less common culprit for significant blow-by on a 7.3.

Interpreting Blow-by Test Results

Here’s a simplified table to help you interpret the blow-by test results and guide your next steps:

| Observation (Oil Filler Cap Test) | Probable Cause | Recommended Action for Troubleshooting |

|---|---|---|

| Minimal/No smoke, cap sits undisturbed. | Normal engine operation. | No immediate action needed for blow-by. Monitor during routine maintenance. |

| Light smoke/vapor, cap slightly ‘dances’, minor pressure. | Mild blow-by, possibly normal for high-mileage engine or restricted breather. |

1. Thoroughly inspect and clean/replace crankcase breather system (doghouse filter, hoses). 2. Monitor oil consumption and leaks. |

| Moderate smoke, cap ‘dances’ vigorously, noticeable pressure. | Significant blow-by, likely restricted breather system OR early signs of internal wear. |

1. IMMEDIATELY clean/replace crankcase breather system. 2. If problem persists, perform Compression and Leak-Down Tests. 3. Inspect turbocharger for seal issues. |

| Heavy, continuous smoke, cap ‘jumps’ off, strong pressure. | Excessive blow-by, severe internal engine wear (piston rings, cylinder walls). |

1. Stop driving immediately to prevent further damage. 2. Perform Compression and Leak-Down Tests to confirm. Prepare for engine rebuild (re-ring or overhaul) or replacement. 3. Check turbocharger thoroughly. |

Solutions and Preventative Maintenance for 7.3 Powerstroke Crankcase Pressure

Once you’ve identified the source of your 7.3 Powerstroke crankcase pressure issue, implementing the correct solution is key. Equally important is adopting preventative maintenance practices to keep your engine in top shape.

Addressing Worn Piston Rings or Cylinder Walls

If your leak-down test confirms significant air escaping past the piston rings, the unfortunate truth is that you’re looking at internal engine wear. Solutions include:

- Engine Re-ring: For moderate wear, replacing just the piston rings might be an option, provided cylinder walls are still within specification. This involves removing the engine, disassembling it, honing the cylinders, and installing new rings.

- Engine Rebuild/Overhaul: For more severe wear, a full engine rebuild is often recommended. This typically includes new pistons, rings, bearings, cylinder honing or boring, and potentially new valves and cylinder head work. This is a significant investment but can restore your 7.3 Powerstroke to like-new condition.

- Engine Replacement: In cases of catastrophic failure or extremely high mileage with extensive wear, a complete engine replacement (new or remanufactured) might be more cost-effective than a full rebuild.

Repairing Turbocharger Issues

If a failing turbocharger is identified as the cause of your excessive crankcase pressure, you have a couple of options:

- Turbo Rebuild: If the turbocharger housing is in good condition and only the seals and bearings are worn, a professional turbo rebuild kit can be used to restore it.

- Turbo Replacement: If the turbocharger housing is cracked, the compressor or turbine wheels are damaged, or the shaft play is excessive beyond repair, a new or remanufactured turbocharger will be necessary.

Maintaining the PCV/Breather System

This is often the simplest and most cost-effective fix and a crucial preventative measure:

- Regular Cleaning/Replacement: Periodically remove and inspect the “doghouse” breather filter on the driver’s side valve cover. Clean it thoroughly or replace it if it’s heavily saturated.

- Hose Inspection: Routinely check all crankcase ventilation hoses for cracks, blockages, or disconnections. Replace any damaged hoses to ensure clear pathways for gas evacuation.

- Consider an Oil Catch Can: While the 7.3 Powerstroke’s system is open, some owners install aftermarket oil catch cans to capture oil vapor before it can escape to the atmosphere, potentially reducing mess and keeping the system cleaner.

Regular Oil Changes & Quality Oil

The quality and cleanliness of your engine oil play a significant role in overall engine health and can indirectly impact crankcase pressure issues:

- Frequent Oil Changes: Regular oil changes with the correct viscosity and specification (e.g., CJ-4 or CK-4 for diesel engines) are vital. Contaminated or degraded oil can accelerate wear on piston rings and cylinder walls.

- High-Quality Oil: Investing in good quality diesel engine oil can help protect internal components from wear, prolonging the life of piston rings and seals.

Tips for Prolonging Engine Life

Beyond specific fixes, adopting good driving and maintenance habits can significantly extend the life of your 7.3 Powerstroke and prevent future blow-by issues:

- Avoid Excessive Idling: Long periods of idling, especially when cold, can lead to fuel dilution in the oil and increased carbon buildup, which is detrimental to piston rings.

- Proper Warm-Up and Cool-Down: Allow your engine to warm up properly before putting it under heavy load, and let the turbo cool down by idling for a minute or two after heavy use before shutting off the engine.

- Maintain Air Filter: A clean air filter ensures your engine breathes properly, preventing contaminants from entering the combustion chamber which can lead to premature wear.

- Timely Fuel Filter Changes: Clean fuel is essential for proper combustion.

Conclusion

Addressing 7.3 Powerstroke crankcase pressure troubleshooting effectively is paramount to maintaining the health, performance, and longevity of your beloved diesel engine. While blow-by can sometimes indicate serious internal wear, often, it’s a manageable issue related to a clogged ventilation system or a worn turbocharger. By systematically diagnosing the problem using the methods outlined in this guide, you can pinpoint the root cause and implement the appropriate solutions.

Don’t let excessive crankcase pressure compromise your 7.3 Powerstroke’s reliability. Proactive inspection, diligent maintenance, and timely repairs are the keys to ensuring your engine continues to deliver the legendary power and dependability it’s known for. Keep a keen eye on those symptoms, follow these troubleshooting steps, and your 7.3 Powerstroke will reward you with many more miles of robust performance.

🎥 Related Video: What causes high crankcase pressure – semi truck diagnostics #shorts

📺 Idle & Emission Solutions

crankcase #semitruck #diagnostictroublecode ATTENTION WIN a Polar Fox APU – Valued at $7000! Truckers, this is BIG!

Frequently Asked Questions

What exactly is crankcase pressure in my 7.3 Powerstroke and why is it important?

Crankcase pressure refers to the internal pressure within the engine’s crankcase, which is the area below the pistons. While some pressure (known as blow-by) is normal, excessive pressure indicates a problem that can significantly impact engine health. Maintaining proper crankcase pressure is crucial for preventing oil leaks, ensuring efficient lubrication, and preserving engine seals.

What are the common symptoms of excessive 7.3 Powerstroke crankcase pressure?

You might notice various signs, including oil leaks from seals like the rear main, front main, valve covers, or the dipstick tube. Other symptoms can include increased oil consumption, a dipstick that pops out of its tube, or a strong diesel exhaust smell in the cabin. In severe cases, you might even hear a whistling sound or see oil residue around the oil fill cap.

What typically causes high crankcase pressure in a 7.3 Powerstroke engine?

The most frequent cause is excessive blow-by due to worn piston rings or cylinder walls, allowing a larger volume of combustion gases to leak into the crankcase. Other contributors include a restricted or clogged crankcase ventilation (CCV) system, a faulty turbocharger compressor seal, or, less commonly, a damaged head gasket. Proper diagnosis is key to identifying the exact source.

How can I accurately test the crankcase pressure on my 7.3 Powerstroke?

You can test crankcase pressure using a manometer or a dedicated blow-by gauge. This tool is typically connected to the oil fill tube opening or the dipstick tube, with the engine at operating temperature. Measure the pressure at idle and then at a higher RPM (e.g., 2000 RPM) to compare against factory specifications or known good values. Some pressure is normal, but excessive readings indicate a problem.

What are the most common solutions for troubleshooting high 7.3 Powerstroke crankcase pressure?

Solutions depend on the root cause, but often involve clearing blockages in the CCV system, which includes the hose, “doghouse” (oil separator), and collector. If blow-by is excessive due to engine wear, more extensive repairs like replacing piston rings or overhauling the engine may be necessary. Always start with the simplest and most common issues first, such as CCV system maintenance.

Is some level of blow-by normal, or should there be no crankcase pressure at all?

It’s important to understand that a small amount of blow-by, where combustion gases escape past the piston rings into the crankcase, is completely normal even in a healthy 7.3 Powerstroke engine. The engine’s crankcase ventilation system is designed to manage and remove this normal amount of pressure. Problems arise only when this blow-by becomes excessive, leading to higher-than-normal crankcase pressure and the associated symptoms.