6.0 Powerstroke Fuel Injector Testing Tools: Ensure Accurate Fuel Delivery

Featured image for this comprehensive guide about 6.0 Powerstroke fuel injector testing tools

Image source: motortrend.com

The 6.0 Powerstroke – a diesel engine known for its incredible power and torque, but also for its complex engineering and, at times, its challenging reliability. If you own or work on one of these formidable machines, you’re likely intimately familiar with the engine’s critical components, especially its fuel injectors. These aren’t your average gasoline injectors; they’re sophisticated pieces of engineering that operate under immense pressure, precisely atomizing fuel to meet the demanding needs of a high-performance diesel engine.

When a 6.0 Powerstroke fuel injector begins to falter, it can lead to a cascade of problems: rough idle, misfires, excessive smoke, loss of power, and even a dreaded no-start condition. The tricky part? Pinpointing the exact issue. Is it a faulty injector? An electrical problem? Low fuel pressure? Or perhaps an issue with the Fuel Injection Control Module (FICM) itself? This is where 6.0 Powerstroke fuel injector testing tools become your most valuable allies. Without the right diagnostic equipment, you’re essentially guessing, which can be both time-consuming and expensive.

In this comprehensive guide, we’ll dive deep into the world of 6.0 Powerstroke fuel injector testing tools. We’ll explore everything from essential scan tools that read the engine’s language to specialized electrical and mechanical testers designed to pinpoint specific failures. Whether you’re a seasoned mechanic or a dedicated DIYer, understanding and utilizing these tools will empower you to accurately diagnose injector-related issues, saving you frustration, time, and money. Let’s equip ourselves with the knowledge and tools needed to keep that 6.0 Powerstroke running strong.

Quick Answers to Common Questions

Why bother with 6.0 Powerstroke fuel injector testing tools?

Investing in 6.0 Powerstroke fuel injector testing tools helps you accurately diagnose issues like misfires or poor fuel economy before costly “guess and replace” repairs. They ensure you only replace what’s truly faulty, saving you significant time and money.

What are some essential 6.0 Powerstroke fuel injector testing tools I should know about?

Key tools include a high-pressure oil test kit for the HPOP system, an injector contribution test with a scan tool, and a simple multimeter for electrical checks. These 6.0 Powerstroke fuel injector testing tools are crucial for proper diagnosis.

Can I really use 6.0 Powerstroke fuel injector testing tools myself, or do I need a shop?

Many basic tests using 6.0 Powerstroke fuel injector testing tools can be done by a DIYer with a good scan tool and some patience. However, complex diagnostics might benefit from a professional’s specialized equipment and expertise.

How do 6.0 Powerstroke fuel injector testing tools help me avoid unnecessary injector replacements?

By accurately identifying whether an injector is truly failing or if the problem lies elsewhere, these specialized 6.0 Powerstroke fuel injector testing tools prevent “guess and replace” repairs. You’ll only swap out what actually needs it, saving significant costs.

What’s the first step to using 6.0 Powerstroke fuel injector testing tools when I suspect an issue?

Start with a good quality scan tool to perform a Cylinder Contribution Test; it’s often the quickest way to identify a weak cylinder. This initial step with 6.0 Powerstroke fuel injector testing tools helps narrow down your diagnostic path.

📋 Table of Contents

- Why 6.0 Powerstroke Injectors Demand Specialized Attention

- The Indispensable Scan Tools: Your First Line of Defense

- Specialized Electrical Testing Tools: Diagnosing FICM and Injector Circuits

- Mechanical & Fuel System Testing Tools: Beyond the Electrical Grid

- Advanced Bench Testing and Professional Solutions

- Best Practices for Effective 6.0 Powerstroke Injector Testing

- Conclusion

Why 6.0 Powerstroke Injectors Demand Specialized Attention

Before we delve into the testing tools, it’s crucial to understand why 6.0 Powerstroke fuel injectors are so unique and, at times, problematic. This context will help you appreciate the importance of each diagnostic step.

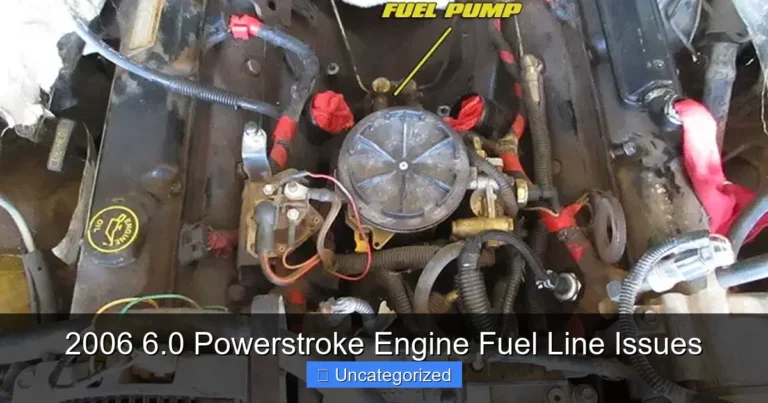

Learn more about 6.0 Powerstroke fuel injector testing tools – 6.0 Powerstroke Fuel Injector Testing Tools: Ensure Accurate Fuel Delivery

Image source: i.pinimg.com

The HEUI System and Its Vulnerabilities

The 6.0 Powerstroke utilizes a Hydraulically Actuated Electronic Unit Injector (HEUI) system. Unlike common rail systems, HEUI injectors use highly pressurized engine oil (up to 3,600 PSI) to amplify fuel pressure within the injector itself. This oil pressure is supplied by the High-Pressure Oil Pump (HPOP), and its timing and volume are controlled by the Injector Pressure Regulator (IPR) and the Injector Control Pressure (ICP) sensor.

| Tool/Equipment | Primary Diagnostic Function | Typical Cost Range (USD) | Key Benefit for 6.0 Powerstroke |

|---|---|---|---|

| Professional Diagnostic Scan Tool | Reads DTCs, live data (FICM sync, IPR, ICP), performs injector buzz test & cylinder contribution test. | $300 – $3000+ | Comprehensive electronic diagnostics; essential for initial fault isolation and verification. |

| FICM Voltage Tester (External) | Measures actual output voltage from the Fuel Injection Control Module (FICM) to the injectors under load. | $80 – $300 | Directly verifies proper power supply to injectors, a very common 6.0L failure point. |

| Multimeter (Ohm/Continuity) | Checks electrical resistance of injector solenoids (spec ~0.3-0.5 ohms) and wiring harness integrity. | $20 – $150 | Identifies internal injector coil shorts/opens or wiring faults causing misfires/no-start conditions. |

| High-Pressure Fuel Pressure Gauge | Monitors fuel delivery pressure to the standpipes and injectors (target 45-70 PSI). | $50 – $200 | Crucial for preventing injector cavitation/failure; low fuel pressure rapidly damages 6.0L injectors. |

| Mechanic’s Stethoscope / Chassis Ear | Physically listens for individual injector solenoid activation during a buzz test or engine cranking. | $15 – $50 | Helps confirm individual injector functionality and differentiate mechanical vs. electrical issues. |

This intricate design, while powerful, introduces several potential failure points:

- Oil Quality and Supply: Dirty or degraded engine oil can damage internal injector components and the HPOP.

- Electrical Dependence: Each injector has an internal solenoid, requiring a precise 48-volt signal from the FICM.

- Sealing: O-rings and internal seals must withstand extreme oil and fuel pressures.

Common 6.0 Powerstroke Injector Failure Modes

Understanding the typical ways these injectors fail helps guide your diagnostic process:

- Stiction (Sticking Injectors): This is perhaps the most common issue. Deposits form on internal injector components (spool valve), causing them to stick. Symptoms include rough idle, misfires, particularly when cold, and even a no-start condition. Often, this isn’t a complete failure but a performance degradation.

- Electrical Failure: The internal solenoid windings can short or open, preventing the injector from firing or causing it to fire improperly. FICM issues (low voltage output) also fall into this category, as the injectors won’t receive the necessary power.

- Internal Fuel/Oil Leaks: Worn O-rings or cracked internal components can allow fuel or oil to leak, leading to fuel in the oil, oil in the fuel, low fuel pressure, or loss of high-pressure oil, impacting other injectors.

- Nozzle/Tip Damage: While less common, carbon buildup or physical damage to the nozzle can lead to poor spray patterns, reduced atomization, and inefficient combustion.

Given this complexity, relying on accurate 6.0 Powerstroke fuel injector testing tools isn’t just a convenience; it’s a necessity.

The Indispensable Scan Tools: Your First Line of Defense

When diagnosing a 6.0 Powerstroke fuel injector issue, a capable scan tool is your absolute starting point. These devices communicate with the engine’s onboard computer (PCM), reading Diagnostic Trouble Codes (DTCs) and monitoring live data, giving you the first crucial clues.

Learn more about 6.0 Powerstroke fuel injector testing tools – 6.0 Powerstroke Fuel Injector Testing Tools: Ensure Accurate Fuel Delivery

Image source: printables.space

Recommended Scan Tools for 6.0 Powerstroke

While generic OBD-II scanners can read basic codes, you’ll need a more advanced tool for in-depth 6.0 Powerstroke injector testing:

- Forscan: A highly popular and affordable software that, when paired with an OBD-II adapter (like an ELM327 USB or Bluetooth adapter), provides dealer-level diagnostic capabilities for Ford vehicles. It’s a favorite among DIYers for its comprehensive features and active community support.

- AutoEnginuity (AE) with Ford Bundle: A professional-grade scan tool offering extensive bidirectional controls and monitoring for the 6.0 Powerstroke. It’s more expensive but provides unparalleled depth of diagnosis.

- Ford IDS (Integrated Diagnostic System): The factory diagnostic tool. If you’re visiting a dealership or a specialized shop, this is what they’ll be using. It offers the most complete set of diagnostic and programming functions.

Key Diagnostic Tests and Parameters with a Scan Tool

Here are the essential tests and data points you’ll access with your 6.0 Powerstroke fuel injector testing tools:

1. The Injector Buzz Test: Listening for Trouble

This is one of the easiest and most informative tests. The PCM commands each injector solenoid to cycle rapidly (buzz). Your scan tool initiates the test, and you listen for a distinct, consistent buzzing sound from each injector. A missing or faint buzz on a specific cylinder immediately flags it as a potential problem. This test checks the electrical integrity of the injector solenoid and its wiring.

- What to look for: A clear, strong buzz from all eight injectors. A weak or absent buzz indicates an electrical issue with that injector or its circuit (FICM, wiring).

- Actionable Insight: If a cylinder fails the buzz test, the next step is usually to check the FICM voltage and the injector’s electrical continuity.

2. Cylinder Contribution Test: Pinpointing Weak Links

The contribution test, also known as a power balance test, is performed with the engine running. The PCM momentarily disables each injector one by one and monitors the drop in engine RPM. A healthy injector, when disabled, will cause a noticeable drop in RPM. An injector that’s already weak or not firing effectively will cause little to no RPM change when disabled, indicating it’s not contributing much to the engine’s power output.

- What to look for: Consistent RPM drop across all cylinders. A cylinder showing little or no drop suggests a weak or dead injector.

- Actionable Insight: This test helps confirm which cylinder(s) are underperforming due to an injector issue, allowing you to focus your efforts.

3. Monitoring Key Live Data Parameters

Your scan tool allows you to monitor dozens of live data PIDs (Parameter Identifiers). Here are the critical ones for 6.0 Powerstroke injector testing:

- FICM Sync: Should be “YES” or “1” (synced). If “NO” or “0,” the FICM isn’t communicating correctly, preventing injector firing.

- FICM LPO (Low Power Output) Voltage / FICM MPower (Main Power) Voltage: Crucial for injector operation. Should ideally be 48.0-48.5V while running, and at least 45V during cranking. Anything below 45V (especially under 42V) is a sign of a failing FICM, which will cause injector performance issues or a no-start.

- ICP (Injector Control Pressure) Sensor: Monitors the high-pressure oil system. Should build to at least 500 PSI during cranking (a typical threshold for starting) and range from 580-3600 PSI while running, depending on load. Low ICP indicates HPOP, IPR, or oil leak issues.

- IPR (Injector Pressure Regulator) Duty Cycle: Shows how hard the IPR is working to maintain ICP. Typically 20-30% at idle, increasing under load. High IPR % at idle (over 35%) with low ICP can indicate an HPOP issue or a high-pressure oil leak.

- EOT (Engine Oil Temperature) & EOT (Engine Coolant Temperature): Ensure they are within operating range and correlate. Injector performance can be affected by oil temperature.

- Fuel Pressure (if equipped with a sensor, or monitored externally): Essential for proper injector function. Should be 45-70 PSI at idle and throughout the RPM range. Low fuel pressure can cause injector stiction and damage.

Specialized Electrical Testing Tools: Diagnosing FICM and Injector Circuits

The 6.0 Powerstroke is as much an electrical marvel as it is mechanical. Many injector problems stem from electrical issues, making specialized electrical 6.0 Powerstroke fuel injector testing tools indispensable.

1. FICM Voltage Tester: The Heartbeat of Your Injectors

The FICM (Fuel Injection Control Module) is arguably the most common electrical component to fail on a 6.0 Powerstroke, and its failure directly impacts injector function. A dedicated FICM voltage tester, or even a good quality multimeter, is crucial.

- Tool: Multimeter (with strong battery) or a dedicated 6.0 Powerstroke FICM Tester (e.g., from FICMrepair.com).

- What to test: Test the main power output from the FICM (MPower) and the logic power (LPower) while cranking and with the engine running.

- Key Readings: As mentioned, aim for 48.0-48.5V while running, and no less than 45V during cranking or under load. Below 42V, especially during cranking, often means FICM failure. The logic voltage (LPower) should be around 12V.

- Actionable Insight: If FICM voltage is consistently low, it needs repair or replacement. A weak FICM causes hard starts, rough idle, and misfires.

2. Multimeter for Injector Harness and Solenoid Checks

A reliable digital multimeter is essential for checking continuity, resistance, and voltage drop in the injector wiring harness and the injector solenoids themselves.

- What to test:

- Injector Solenoid Resistance: With the engine off and FICM disconnected, you can test the resistance of each injector solenoid through the valve cover gasket connector. Typically, good resistance is around 0.1-0.3 ohms (very low). Out-of-spec readings or an open circuit indicate a faulty injector solenoid.

- Wiring Harness Continuity: Check for opens or shorts in the wiring between the FICM and the injector connectors.

- Voltage Drop: Check for excessive voltage drop across the injector harness, which can starve the injectors of power.

- Actionable Insight: Pinpointing an open circuit or incorrect resistance can directly identify a bad injector or a wiring problem.

3. Power Probe / Test Light: Quick Circuit Checks

For quick checks of power and ground, a Power Probe or even a basic test light can be useful, though less precise than a multimeter. Be extremely careful when using these around sensitive electronics. A Power Probe can provide a fused 12V or ground to a component, but *never* directly power a 6.0 injector with 12V, as it requires 48V.

- Use Case: Checking for 12V power at the FICM inputs or verifying ground connections.

- Actionable Insight: Can quickly confirm if a circuit is dead or live.

Mechanical & Fuel System Testing Tools: Beyond the Electrical Grid

While electrical issues are common, mechanical problems within the fuel and oil systems can also mimic injector failure. These 6.0 Powerstroke fuel injector testing tools help diagnose those critical pressure-related issues.

1. Fuel Pressure Gauge: The Lifeblood of Your Injectors

This is arguably one of the most critical mechanical tests. Low fuel pressure is a primary cause of 6.0 Powerstroke injector stiction and premature failure. The 6.0’s injectors require adequate fuel pressure to operate correctly and be cooled.

- Tool: A reliable fuel pressure gauge kit that connects to the fuel bowl or banjo bolt. Many kits have a long hose so you can monitor pressure while driving.

- Key Readings: Minimum 45 PSI at idle, preferably 50-60 PSI. Pressure should remain above 45 PSI under all load conditions.

- Actionable Insight:

- If pressure is consistently below 45 PSI, you likely have a failing fuel pump (HFCM), clogged fuel filters, or a leak. This must be addressed immediately to prevent injector damage.

- Fluctuating pressure can indicate a dying fuel pump or issues with the fuel pressure regulator.

2. Air Test Kit / Injector O-Ring Leak Detector: Identifying Internal Leaks

High-pressure oil leaks within the oil rail or at the injector O-rings are notoriously difficult to find but can cause low ICP and no-start conditions. An air test kit helps pressurize the high-pressure oil system with shop air, allowing you to listen for leaks.

- Tool: A specialized 6.0 Powerstroke High-Pressure Oil System Air Test Kit. This typically consists of a fitting that replaces the IPR valve, allowing you to connect an air hose.

- Procedure: With the valve covers off (or using an in-cab listening device), remove the IPR and install the air fitting. Apply 100-120 PSI of shop air.

- What to listen for: Hissing sounds indicate a leak. Common culprits are:

- Injector O-rings: Listen at each injector for a strong hiss.

- Dummy Plugs & Standpipes: Listen around the oil rail for leaks.

- HPOP Cover: Check for leaks here.

- STC Fitting: This notoriously weak fitting can also leak (though often requires removal of components to access).

- Actionable Insight: Pinpointing an oil leak is crucial for restoring ICP and getting the engine to start or run smoothly.

3. Oil Pressure Gauge: HPOP and IPR Health

While the ICP sensor provides a digital reading, a mechanical oil pressure gauge can be useful for independently verifying the low-pressure oil system (engine oil pressure) and ensuring the HPOP has sufficient supply.

- Tool: Standard engine oil pressure gauge.

- Use Case: Verifying baseline engine oil pressure and checking for adequate oil supply to the HPOP. Low engine oil pressure can starve the HPOP, leading to low ICP.

- Actionable Insight: If engine oil pressure is low, the problem extends beyond the injectors to the engine’s lubrication system.

4. Compression Tester (General Diesel Tool)

While not a direct injector testing tool, a diesel compression tester is a fundamental diagnostic tool for any diesel engine. Severe injector issues or misfires can sometimes be confused with or compounded by low compression in a cylinder.

- Use Case: If all other injector tests come back inconclusive, or if you suspect a deeper engine issue (e.g., worn rings, bent valve), a compression test can rule out mechanical engine problems.

- Key Readings: A healthy 6.0 Powerstroke should have compression readings above 350 PSI, with no more than 10% variance between cylinders.

- Actionable Insight: Low compression on a cylinder means the problem is internal engine damage, not just an injector.

Advanced Bench Testing and Professional Solutions

Sometimes, even with all the on-vehicle 6.0 Powerstroke fuel injector testing tools, a definitive answer remains elusive. This is where more advanced, off-vehicle testing comes into play, usually performed by specialized diesel shops.

1. Diesel Injector Flow Bench: The Gold Standard for Performance

A diesel injector flow bench is a highly specialized and expensive piece of equipment. It allows technicians to remove an injector and test its performance under various simulated engine conditions.

- What it tests:

- Flow Rate: Measures how much fuel the injector delivers at different pressures and pulse widths.

- Spray Pattern: Visual inspection of the fuel spray for proper atomization and distribution.

- Response Time: How quickly the injector opens and closes.

- Leakage: Checks for internal and external fuel leaks.

- Electrical Integrity: Often includes advanced electrical diagnostics beyond a simple resistance check.

- Actionable Insight: This test provides the most accurate assessment of an injector’s health and performance, identifying subtle issues like partially clogged nozzles or slow response times that on-vehicle tests might miss. It’s often used for rebuilding and calibrating injectors.

2. Hot Shot Secret/Rev-X/Lubricity Additives (as a Diagnostic/Preventative Measure)

While not a “testing tool” in the traditional sense, high-quality oil additives designed to combat stiction (like Hot Shot’s Secret Stiction Eliminator or Rev-X Oil Additive) can sometimes serve as a diagnostic aid. If an injector issue significantly improves or resolves after adding one of these products, it strongly suggests that stiction was the primary problem.

- Use Case: If you suspect stiction, adding one of these can sometimes free up the injector, potentially avoiding costly replacement. It can also help confirm the diagnosis.

- Actionable Insight: These additives are excellent for preventative maintenance and can often buy you time or even fully resolve minor stiction issues, confirming the nature of the problem without disassembly.

Best Practices for Effective 6.0 Powerstroke Injector Testing

Having the right 6.0 Powerstroke fuel injector testing tools is only half the battle. Knowing how to use them effectively and following a logical diagnostic process is equally important. Here are some best practices:

1. Start with the Basics: Visual Inspection & Fluid Levels

Before plugging in a single tool, always perform a thorough visual inspection. Check for:

- Fluid Levels: Ensure engine oil and coolant levels are correct.

- Leaks: Look for oil, fuel, or coolant leaks around the engine.

- Wiring: Inspect the FICM, injector harness, and other sensor connectors for damage, corrosion, or loose connections.

- Fuel Filters: Check when they were last replaced. Clogged filters are a common cause of low fuel pressure.

2. Follow a Diagnostic Tree: Don’t Guess

Resist the urge to randomly swap parts. A systematic approach saves time and money. Start with the easiest, least intrusive tests (like a scan tool buzz test) and progressively move to more complex ones (like an air test or removal of injectors).

- Scan for DTCs.

- Perform a buzz test and contribution test.

- Monitor FICM voltage.

- Check fuel pressure.

- If issues persist, conduct an air test for high-pressure oil leaks.

- Only then, consider removing valve covers for electrical checks or injectors for bench testing.

3. Document Your Findings

Keep a log of all your readings, test results, and any actions taken. This helps track changes, identify intermittent issues, and provides valuable data if you need to consult with a professional.

4. Regular Maintenance as Prevention

Many 6.0 Powerstroke injector issues can be prevented with diligent maintenance:

- Timely Oil Changes: Use high-quality CJ-4/CK-4 rated 5W-40 or 15W-40 synthetic oil at recommended intervals. Good oil is critical for the HEUI system.

- Fuel Filter Replacement: Replace both the upper and lower fuel filters every 10,000-15,000 miles, or more frequently if using poor-quality fuel.

- Use Fuel Additives: A good quality fuel additive with lubricity and cetane improvers can help keep injectors clean and protected.

5. Invest in Quality Tools

While some tools can be rented or borrowed, frequent work on a 6.0 Powerstroke justifies investing in your own quality diagnostic equipment. Cheap tools can give inaccurate readings, leading to misdiagnosis and further frustration.

Common 6.0 Powerstroke Injector Symptoms and Corresponding Testing Tools

Here’s a quick reference table to help guide your diagnostic efforts:

| Symptom | Potential Cause | Primary Testing Tools | Key Readings/Indicators |

|---|---|---|---|

| Rough Idle / Misfire (especially cold) | Sticking Injector, Low FICM Voltage, Low Fuel Pressure | Scan Tool (Buzz Test, Contribution Test), FICM Voltage Tester, Fuel Pressure Gauge | Buzz Test failure, low contribution, FICM <45V, Fuel Pressure <45 PSI |

| No Start (Cranks but won’t fire) | Low FICM Voltage, Low ICP (HPOP/IPR/Leak), FICM Sync failure | Scan Tool (FICM Sync, ICP/IPR PIDs), FICM Voltage Tester, Air Test Kit | FICM Sync “NO”, ICP <500 PSI, FICM <45V, air leak detected |

| Excessive Smoke (White/Gray) | Sticking Injector, Poor Atomization, Low Fuel Pressure | Scan Tool (Contribution Test), Fuel Pressure Gauge, (ultimately Flow Bench for definitive) | Low contribution on cylinder, Fuel Pressure <45 PSI |

| Loss of Power / Hesitation | Weak Injector, Low Fuel Pressure, Low ICP | Scan Tool (Contribution Test, ICP/IPR PIDs), Fuel Pressure Gauge | Low contribution, ICP not building under load, Fuel Pressure <45 PSI |

| Fuel in Oil / Oil in Fuel | Leaking Injector O-rings, Failed Injector | Visual Inspection of Fluids, Air Test Kit (for O-rings), (ultimately Flow Bench for definitive) | Oil level rising/fuel smell in oil, fuel visible in fuel bowl, air leak from injector |

Conclusion

The 6.0 Powerstroke is a magnificent engine, but its sophisticated fuel injection system requires an equally sophisticated approach to maintenance and diagnosis. Injector issues are among the most common and frustrating problems faced by 6.0 Powerstroke owners. However, by equipping yourself with the right 6.0 Powerstroke fuel injector testing tools and adopting a systematic diagnostic process, you can confidently identify and address these challenges.

From the essential scan tool that speaks your engine’s language to the specialized electrical testers that verify FICM health, and the mechanical gauges that confirm fuel and oil pressures – each tool plays a vital role. Remember, an accurate diagnosis is the cornerstone of an effective repair. Don’t let injector problems sideline your powerful truck. Invest in knowledge, invest in quality tools, and keep your 6.0 Powerstroke roaring down the road for years to come. Your truck (and your wallet) will thank you.

🎥 Related Video: What Are Diesel Fuel Injector Trim Codes? Let HHP Show You!

📺 Highway and Heavy Parts

Diesel Fuel Injector Trim Codes: Trim codes or trim files are essential for the injection process in your diesel engine’s fuel injectors …

Frequently Asked Questions

Why is testing my 6.0 Powerstroke fuel injectors so important for my truck’s health?

Regular testing helps ensure your engine is receiving the correct amount of fuel, which is crucial for optimal performance, fuel efficiency, and preventing costly engine damage. It allows you to identify failing injectors before they cause wider issues or breakdowns.

What are the most common 6.0 Powerstroke fuel injector testing tools available?

Common 6.0 Powerstroke fuel injector testing tools include diagnostic scanners for “buzz tests” and “contribution tests,” and specialized kits for measuring injector return flow. These tools help assess electrical function and fuel delivery precision, providing insight into injector health.

What symptoms suggest I need to use 6.0 Powerstroke fuel injector testing tools?

Look out for signs like rough idling, misfires, excessive white or black smoke, decreased fuel economy, or difficulty starting. These symptoms often point to a failing injector that needs diagnosis with appropriate testing tools.

How do I perform a basic test using 6.0 Powerstroke fuel injector testing tools?

A common starting point is a “buzz test” using a diagnostic scanner, which checks the electrical integrity of each injector by cycling it. For fuel delivery issues, a return flow test kit can measure how much fuel each injector is returning, indicating internal wear or blockage.

Can I perform these 6.0 Powerstroke fuel injector tests myself, or should I go to a professional?

While basic diagnostic scanner tests can be done by a competent DIY mechanic, more advanced tests like precise return flow measurements or removal for bench testing often require specialized 6.0 Powerstroke fuel injector testing tools and expertise. Consulting a professional ensures accurate diagnosis and avoids potential misdiagnosis.

What specific injector problems can these 6.0 Powerstroke fuel injector testing tools help diagnose?

These 6.0 Powerstroke fuel injector testing tools are invaluable for identifying common issues such as stiction (where an injector gets stuck), internal leakage, poor atomization, or electrical failures. Pinpointing the exact problem helps target repairs effectively and saves time and money.