Complete Guide on Installing Torque Converter to Flexplate: Step-by-Step Instructions

Are you in the process of installing a torque converter to a flexplate and feeling a bit overwhelmed? Don’t worry, you’re not alone. Installing a torque converter to a flexplate can be a daunting task, especially for those who are new to automotive work. However, with the right tools and a bit of patience, this process can be completed successfully.

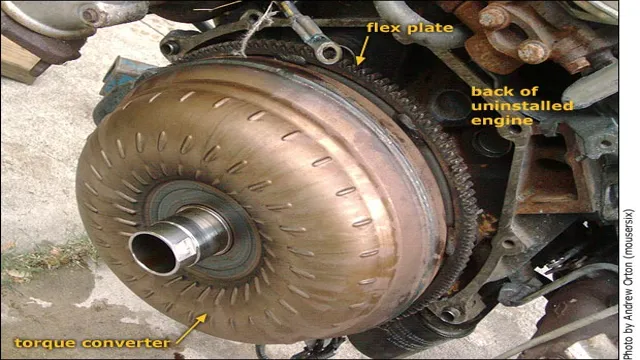

A torque converter is an important component in an automatic transmission system that helps to transmit power from the engine to the wheels. And, the flexplate is the component that connects the engine to the torque converter. In this blog, we’ll cover the steps you need to take to install a torque converter to a flexplate like a pro! So, grab your tools and let’s get started!

Gather the necessary tools

One of the essential steps in installing a torque converter to a flexplate is gathering the necessary tools. First, you’ll need a torque wrench, which will allow you to tighten the bolts to the exact specifications provided by the manufacturer. Additionally, you’ll need a socket set with a variety of sizes, as well as a pry bar that will help you position the torque converter correctly.

You may also require a rubber mallet for tapping and aligning parts into position. Finally, a floor jack and jack stands will be necessary for getting under the car and accessing the transmission. Having all of these tools ready and easily accessible prior to beginning the installation process will save you time and frustration later on, ensuring that the job is completed smoothly and efficiently.

Torque Converter, Flexplate, Socket Wrench, Torque Wrench

If you’re going to be working on your car’s transmission or engine, you’ll need to gather some essential tools before you begin. A torque converter is a necessary component for automatic transmissions that allows your car to shift gears smoothly. A flexplate is another crucial component that connects the engine to the torque converter.

You’ll want to make sure you have a socket wrench on hand that fits the bolts for both the torque converter and flexplate. Using a torque wrench is key to ensuring that you tighten the bolts to the proper torque specification. This is important for the safety and longevity of your car.

By having these tools ready to go, you’ll be able to work efficiently and effectively on your car’s transmission or engine. So, before you start your next car project, make sure you have the necessary tools, including a torque converter, flexplate, socket wrench, and torque wrench.

Prepare the transmission and engine

Installing a torque converter to the flexplate is a crucial step in preparing the transmission and engine. First, ensure that both pieces are clean and free of debris. Make sure the torque converter is properly aligned and gently slide it onto the input shaft of the transmission.

Once it is seated, rotate and push gently until it engages with the transmission. Then, place the flexplate over the torque converter and make sure the bolt holes align. Use the manufacturer-recommended bolts and tighten them in a crisscross pattern to ensure even pressure.

Finally, rotate the engine by hand to ensure that the torque converter and flexplate move together smoothly. Properly installing the torque converter to the flexplate can prevent damage and ensure optimal performance.

Align the torque converter bolt holes with flexplate holes

When it comes to installing a new engine and transmission into a vehicle, one important step is to align the torque converter bolt holes with the flexplate holes. This ensures that the transmission and engine will connect properly and function smoothly. To prepare for this step, make sure that the engine and transmission are securely mounted in place.

Then, rotate the torque converter until the bolt holes line up with the corresponding holes on the flexplate. It’s important to take your time with this step and ensure that the alignment is precise, as any misalignment can cause damage to the engine and transmission over time. Once you have properly aligned the bolt holes, insert the bolts and tighten them with a torque wrench to the manufacturer’s specifications.

This will ensure that the torque converter and flexplate are securely fastened together, allowing for smooth operation of your vehicle’s drivetrain. Overall, properly aligning the torque converter bolt holes with the flexplate holes is a crucial step in installing a new engine and transmission. By taking the time to do it correctly, you can ensure that your vehicle will function smoothly and efficiently, without any unnecessary wear and tear on the engine and transmission components.

Install the torque converter to flexplate

Installing the torque converter to the flexplate is a crucial step when assembling an automatic transmission. First, you need to ensure that the torque converter and flexplate are matched, and both have the same bolt pattern. Then, align the torque converter studs with the flexplate’s holes.

Once you have them lined up, gently push the converter towards the flexplate while turning it clockwise. You should feel it click into place with a gentle movement. Afterward, tighten the bolts to spec and ensure that the torque converter rotates freely.

Remember to install a new torque converter seal to prevent fluid leaks. When done correctly, installing a torque converter to the flexplate is not complicated, but it’s essential to follow all the steps to avoid costly mistakes. So, take your time and double-check everything, and you’ll have a smooth-running transmission in no time!

Use socket wrench to tighten bolts evenly

As you install the torque converter to flexplate, it’s essential to use a socket wrench to tighten bolts evenly. This will ensure that the converter is firmly attached to the flexplate and doesn’t move around. Don’t make the mistake of overtightening the bolts, as this can cause damage to the threads.

Use a torque wrench to get the exact torque spec needed for your specific vehicle. Keep in mind that when installing the torque converter, you want to make sure it’s lined up properly. The splines on the torque converter should align with the input shaft on the transmission.

If it’s not lined up correctly, you won’t be able to get the transmission to engage properly. Once the torque converter is in place and secured, you can move on to the next step in your transmission installation. Remember to take your time and be careful with the bolts and torque specifications.

Doing so will ensure a smooth installation process and will help avoid any costly mistakes. So, next time you’re working on your car’s transmission, remember to use a socket wrench to tighten bolts evenly and make sure your torque converter is properly aligned and secured. It might take a little extra effort, but it will be worth it in the long run.

Trust me, your car will thank you.

Reconnect transmission and engine

Installing a torque converter to a flexplate is not as difficult as it may seem. Once you have removed the old torque converter, the next step is to position the new one onto the transmission input shaft. It’s important to make sure that the torque converter is fully seated and properly aligned with the transmission input shaft before proceeding.

Next, connect the torque converter to the flexplate by rotating it slightly until the mounting holes line up. Insert the bolts and tighten them to the torque specification recommended by the manufacturer. Once the torque converter is securely attached to the flexplate, reattach the transmission to the engine, making sure to align the guide pins on the transmission with the holes on the engine block.

Finally, tighten the transmission pan bolts and fill the transmission with fluid to the appropriate level. With these steps completed correctly, your torque converter will be safely and securely installed to the flexplate, ensuring proper functionality of your vehicle.

Ensure torque converter and flexplate are aligned

When reconnecting your transmission and engine, it’s critical to ensure that the torque converter and flexplate are aligned properly. This can prevent costly damage to your vehicle. If the torque converter and flexplate are not aligned, the transmission will not engage with the engine correctly, and you may suffer from a loss of power or problems shifting gears.

To check the alignment, rotate the flexplate and torque converter by hand, making sure that they move in unison. If there is any resistance or grinding, there is likely a misalignment that needs to be addressed. So, take the time to double-check before you tighten up the bolts and move on to the next step.

Trust us, it’s worth it to avoid future problems down the road.

Test for successful installation

Installing a torque converter to a flexplate is a crucial step in ensuring the smooth operation of an automatic transmission system. To begin, it’s important to properly align the flexplate and torque converter with each other before installation. Slide the torque converter onto the input shaft of the transmission and rotate it until it fully seats.

Next, align the bolt holes on the flexplate with the torque converter’s bolt holes. Insert bolts and tighten them to the manufacturer’s recommended torque settings. It’s important to use the correct torque specifications to avoid damage to the flexplate and torque converter.

Once secured, gently rotate the torque converter to ensure that it rotates freely and smoothly. With the converter and flexplate properly installed, the automatic transmission system is ready for its next adventure on the open road.

Start the car and check for any abnormal sounds or issues

After successfully installing a new part or component in your car, the next step is to test whether the installation was a success or not. Start the engine and listen carefully for any abnormal sounds or issues. A successful installation should result in a quiet and smooth engine start-up.

Any unusual sounds such as knocking, rattling, or squealing could indicate a problem and should not be ignored. It’s also important to check if the new component is functioning properly. For instance, if you have replaced the brakes, test them by driving the car and making a few sudden stops.

If everything feels okay, then it’s a sign that the installation was a success. However, if you are still experiencing issues, it’s best to take your car to an expert mechanic who can diagnose the problem and offer a lasting solution. Remember, successful installation is crucial for the overall performance and safety of your vehicle, so always test new components before hitting the road.

In conclusion

In conclusion, installing a torque converter to a flexplate can be a daunting task, especially if you’re not familiar with the process. However, with the right tools and guidance, you can successfully carry out this procedure. The first step is to ensure that both the torque converter and flexplate are clean and free of any debris or debris.

Next, align the bolt holes on the torque converter with those on the flexplate and then bolt the two together. It’s important to tighten the bolts evenly to avoid any imbalances or misalignments that could affect the performance of your vehicle. Finally, double-check everything before starting your car to ensure that your installation has been carried out safely and correctly.

By following these steps, you can install a torque converter to a flexplate like a professional, giving your vehicle the smooth, efficient power transfer that it needs. With patience, focus, and the right tools, anyone can carry out this procedure with ease.

Follow these steps to ensure a successful installation of torque converter to flexplate.

In conclusion, installing a torque converter to a flexplate may seem like a daunting task, but it can be done successfully with the right approach. By following the steps outlined in this guide, you can ensure that the process is as smooth and stress-free as possible, without compromising the performance of your vehicle. From selecting the right torque converter and flexplate combination to following the proper torque specifications and testing for leaks and other issues, each step is critical to the overall success of the installation.

With a little patience and attention to detail, you can enjoy the benefits of a properly-functioning torque converter and flexplate combination, including improved drivability, better fuel efficiency, and enhanced overall performance. So why wait? Get started on your installation today and see the difference for yourself. Remember, every step counts, and every detail matters.

Conclusion

And that, dear friends, is how you connect the heart and soul of your vehicle – the engine – to the wheels that make it go vroom vroom. Installing a torque converter to a flexplate may seem like a daunting task, but with the right tools, a bit of patience, and some good old elbow grease, it can be a breeze. So go forth, fellow gearheads, and conquer that torque converter like the automotive geniuses you are.

Just remember to tighten those bolts and torque ’em to spec!”

FAQs

What tools do I need to install a torque converter to a flexplate?

To install a torque converter to a flexplate, you will need a torque converter holding tool, a flexplate locking tool, a torque wrench, and a socket set.

Is it necessary to align the torque converter to the flexplate before installation?

Yes, it is crucial to align the torque converter to the flexplate before installation to ensure proper operation and prevent damage to the transmission. You can use an alignment tool to ensure proper alignment.

Can I install a new torque converter to an old flexplate?

It is recommended to install a new flexplate when installing a new torque converter. However, if the old flexplate is in good condition and shows no signs of damage or wear, it can be reused after cleaning and inspection.

How tight should the torque converter bolts be tightened during installation?

The torque converter bolts should be tightened to the manufacturer’s specifications, typically around 35-40 ft-lbs. It is essential to use a torque wrench and tighten the bolts evenly to prevent damage to the converter or flexplate.