Ultimate Guide to Installing Freeze Plugs: Keep Your Engine Running Smoothly

If you’re experiencing leaking coolant or low levels, it might be time to replace your freeze plugs. Also known as expansion plugs or welch plugs, freeze plugs are an important part of your vehicle’s cooling system. But how do you install them? Don’t worry, it’s not as difficult as it may seem.

In this blog, we’ll walk you through the step-by-step process of how to install freeze plugs, so you can get back on the road with a fully functioning cooling system. Whether you’re a seasoned mechanic or a DIY beginner, we’ve got you covered. So, let’s dive into the world of freeze plugs and learn how to install them like a pro.

Gather Necessary Tools

Before starting the installation process of freeze plugs, it’s important to gather all necessary tools. These include a socket wrench set, a sealant, a screwdriver, a hammer, and a freeze plug installation tool that fits the size of your engine’s freeze plugs. It’s crucial to ensure that the installation tool is the appropriate size, as any deviation can cause leakages.

Additionally, it’s important to use the correct sealant to protect against any potential leaks. Once you have gathered all necessary tools, you can proceed with the installation process, ensuring that everything is properly tightened to prevent any future issues. With these necessary tools at hand, you’ll be ready to install freeze plugs like a pro.

Socket Wrench

When it comes to using a socket wrench, having the right tools is essential. Before you begin working on your project, make sure you gather all the necessary tools. You will need a socket wrench set, which includes sockets of different sizes.

Look for a ratcheting socket wrench, which allows you to tighten and loosen bolts quickly and easily. Additionally, you may need extensions for your socket wrench, which come in different lengths and help you reach bolts in hard-to-reach areas. It’s also important to have a good quality torque wrench, which helps you tighten bolts to the exact amount of force needed.

By having the right tools, you can ensure that your socket wrench is easy to use and effective, allowing you to complete your project quickly and efficiently.

Rubbing Alcohol

Rubbing alcohol is a handy tool to have around the house – especially during the pandemic. But before you can use it to disinfect surfaces or clean wounds, you need to make sure you have the necessary tools on hand. First and foremost, you’ll need the rubbing alcohol itself.

Most drugstores and supermarkets carry it, and it’s available in various strengths, so be sure to choose the one that’s appropriate for your needs. You’ll also want to grab some cotton balls, swabs, or gauze to apply the alcohol, as well as gloves to protect your skin from the harsh effects of the alcohol. And don’t forget a container or spray bottle to keep the rubbing alcohol in – this will make it easier to use and store.

By gathering all of these essential tools, you’ll be well prepared to use rubbing alcohol effectively and safely.

Freeze Plug Kit

If you’re planning to replace the freeze plugs in your engine, you’ll need to gather some necessary tools to get the job done. One essential tool you’ll need is a socket wrench set with a variety of socket sizes to remove the freeze plugs. Additionally, a rubber mallet or hammer and punch will come in handy for tapping out the old freeze plugs.

You may also need pliers, a scraper, and a wire brush to clean the area around the freeze plugs before installing the new ones. It’s always a good idea to have some gasket sealant on hand as well to ensure a tight seal. With the right tools and a bit of patience, replacing the freeze plugs can be a simple and straightforward process that will help keep your engine running smoothly.

Prepare the Engine

When it comes to installing freeze plugs in your engine, preparation is key. The first step is to remove any old freeze plugs that may be in place to ensure a clean surface for the new plugs to be installed. Once the old plugs have been removed, you will need to thoroughly clean the area around the plug holes with a wire brush and some degreaser.

This will help to remove any debris or corrosion that may be present, which could affect the new freeze plugs’ effectiveness. After cleaning, it’s a good idea to use a high-quality sealant around the edges of the new freeze plugs to ensure a tight seal. Finally, take your time when installing the new plugs, making sure they are seated correctly, and tightened securely.

With proper preparation and careful installation, your engine will be protected from freeze damage.

Drain Coolant System

When preparing your engine for maintenance, one of the essential steps is draining the coolant system. This process involves removing the old coolant from the engine and replacing it with fresh coolant to keep your engine temperature regulated. To begin this process, make sure your engine is cool and the vehicle is parked on a flat surface.

Locate the drain plug on the radiator and place a pan underneath to catch the old coolant. Open the drain plug and wait for the coolant to drain. Once the coolant has completely drained, close the drain plug and refill the coolant system with new coolant.

Remember to follow the manufacturer’s recommended coolant type and mix ratio for your vehicle. This simple step will help keep your engine running smoothly and avoid overheating issues. It is recommended to drain the coolant system every 30,000 miles or every 2-3 years.

By doing this, you’ll prevent costly engine repairs and ensure your vehicle’s longevity.

Clean Area Around Freeze Plug

When it comes to preparing your engine, one important step is cleaning the area around the freeze plug. This plug is located on the engine block and is responsible for releasing coolant in case of an overheat or freeze situation. Without proper cleaning, debris and dirt can get into the plug and cause leaks or blockages.

To clean the area, start by using a brush or rag to remove any loose dirt or debris. Then, use a degreaser to remove any oil or grime buildup. After the area is clean, make sure to inspect the freeze plug for any signs of damage or wear.

It’s also a good idea to have a replacement freeze plug on hand just in case it needs to be replaced. By properly preparing your engine and cleaning the area around the freeze plug, you can prevent future issues and potentially costly repairs.

Inspect Freeze Plug Area for Damage

When preparing your engine, one crucial area that should not be overlooked is the freeze plug area. This is because the freeze plug, also known as an expansion plug, acts as a safety valve to prevent the engine block from cracking due to frozen coolant or overheating. As such, it’s essential to inspect the freeze plug area for any damage that may hinder its ability to do its job.

Some of the things to look out for include cracks, leaks, or corrosion around the plug area. In some cases, the freeze plug may even pop out, causing a significant coolant leak and engine damage. Therefore, it’s crucial to ensure that the freeze plugs are firmly in place, and any damaged ones are replaced before starting the engine.

With this simple step, you can prevent costly engine repairs down the line and keep your car running smoothly.

Remove Old Freeze Plug

If you’re wondering how to install freeze plugs, the first step is to remove the old ones. This can be a bit tricky, but with a little patience and some basic tools, you can get it done. Start by locating the freeze plugs on your engine.

On most engines, they will be located on the side of the engine block, near the bottom. Once you’ve located the freeze plugs, you’ll need to use a punch and hammer to knock out the old ones. Make sure you have a bucket or pan underneath the engine to catch any coolant that may leak out during the process.

Once the old plugs are removed, you’ll need to clean the area thoroughly to ensure a good seal for your new plugs. With the old plugs out of the way, you can move on to the next steps of the installation process. Remember to take your time and work carefully, as damaging the engine block during this process can be costly and time-consuming.

Apply Pressure to the Plug

When it comes to replacing an old freeze plug, it’s crucial to apply pressure in the right way to avoid damaging the surrounding area. First, locate the freeze plug and use a pry bar or screwdriver to gently work it out. Once it’s loose, you can use pliers or another tool to grip the edge and give it a good tug.

However, be careful to apply pressure evenly and not pull too hard, or you risk breaking the plug off inside the engine block. This can cause serious damage, not to mention create a major headache when it comes to removing the leftover piece. When in doubt, don’t hesitate to seek out professional help.

With the right tools and techniques, experts can remove even the most stubborn freeze plugs with ease.

Use Socket Wrench to Loosen Plug

Removing an old freeze plug can be a daunting task, but with the right tools and technique, you can get the job done with ease. One helpful tool to use is a socket wrench, which can help you loosen the plug and remove it from its housing. First, locate the freeze plug and position the socket wrench head over it.

Apply pressure to turn the wrench in a counter-clockwise motion until the plug starts to budge. Once it becomes loose, you can use your fingers to remove the freeze plug from the housing. Remember to wear protective gear such as gloves and goggles to keep yourself safe from any injuries while removing the plug.

By utilizing a socket wrench, you can quickly and efficiently remove old freeze plugs and move on to the next step of your engine repair.

Remove Old Plug with Pliers

Removing an old freeze plug may seem like a daunting task, but with the right tools and a little bit of know-how, it can be done quickly and easily. One of the first steps in this process is to remove the old plug with pliers. This can be done by carefully positioning the pliers around the edges of the plug and gently twisting until it comes loose.

It’s important to be careful during this process, as applying too much force or twisting too hard can damage the surrounding area of the engine block. Once the old plug is removed, it’s important to clean the area thoroughly before installing a new plug. With a little bit of patience and some basic hand tools, replacing a freeze plug can be a DIY job that saves you time and money.

So if you’re experiencing leaks from your engine block, consider checking the freeze plugs and replacing them if needed.

Install New Freeze Plug

Installing a new freeze plug isn’t as complicated as it may seem at first glance. With a few basic tools, some elbow grease, and a bit of know-how, this task can be accomplished in no time. Before beginning the process, it’s important to locate the freeze plugs that need replacing and ensure that the engine is cool.

Remove any hoses, belts, or other components that may be in the way of the freeze plug. Once access is gained, it’s time to remove the old freeze plug. A screwdriver, hammer, or pry bar can all be useful tools in this step.

Once the old plug is out, clean the area thoroughly, and insert the new freeze plug. A socket or freeze plug installation tool can be helpful when inserting the new plug. Gently tap the plug into place until it’s flush with the engine block.

Lastly, double-check that the area is clean, replace any components removed, and fill the engine with coolant before starting it up. With these simple steps, you’ll be able to install a new freeze plug like a pro!

Clean Area with Rubbing Alcohol

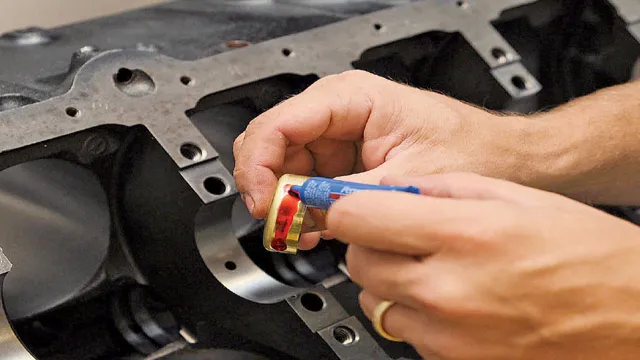

When installing a new freeze plug, it’s important to ensure that the area is clean and free from any contaminants that could cause the new plug to fail. To do this, you can use rubbing alcohol to clean the area and remove any debris or residue. Simply apply the rubbing alcohol to a clean cloth and gently wipe the area around the freeze plug until it’s free from any dirt or grime.

Then, you can proceed with installing the new freeze plug, making sure to coat the edges with some sealant to ensure a tight fit. With a clean area and a properly installed freeze plug, you can rest assured that your engine is running smoothly and efficiently. So, take the time to clean the area with rubbing alcohol before installing your new freeze plug – your engine will thank you.

Lubricate New Plug with Oil

When it comes to replacing a freeze plug in your engine block, it’s important to take the necessary precautions to ensure it’s done correctly. One crucial step is lubricating the new plug with oil before installation. This not only makes it easier to slide the plug into place but also helps to create a tighter seal.

Without proper lubrication, you risk damaging the new plug or causing it to leak, leading to further issues down the line. To lubricate the plug, simply apply a small amount of engine oil to the outer rim before inserting it into the designated hole. This simple step can save you time, money, and a headache in the long run.

So, don’t forget to oil up before installing a new freeze plug.

Insert New Plug into Hole

If you’re experiencing coolant leaks, it may be due to a damaged or corroded freeze plug. Fortunately, replacing them is a relatively simple process. To install a new freeze plug, you’ll need to begin by locating the damaged one.

These plugs are typically found on the sides of the engine block and are identified as circular indentations. Once you’ve located the damaged plug, you’ll need to remove it by carefully tapping around the edges with a large screwdriver or punch until it pops out. Next, clean the area thoroughly and install the new plug by inserting it into the hole with a flat tool.

Use a hammer to tap it firmly into place until it’s flush with the engine block. And that’s it! With a bit of elbow grease, you can save yourself time and money by replacing a damaged freeze plug on your own.

Apply Pressure to Securely Seat Plug

When it comes to installing a new freeze plug in your engine, it’s important to make sure it’s securely seated to avoid any possible leaks. Applying pressure is the key to achieving this. Before inserting the plug, thoroughly clean the area where it will be installed.

Then, carefully align the plug over the opening and begin to apply pressure evenly with a plug installation tool or a socket and hammer. Don’t rush, take your time and gradually increase the pressure until the plug is securely seated. Once it’s in place, make sure to double-check that there are no gaps or unevenness, which could cause problems down the road.

By taking these steps and applying the necessary pressure, you can feel confident that your new freeze plug will work properly and keep your engine running smoothly.

Refill Coolant System

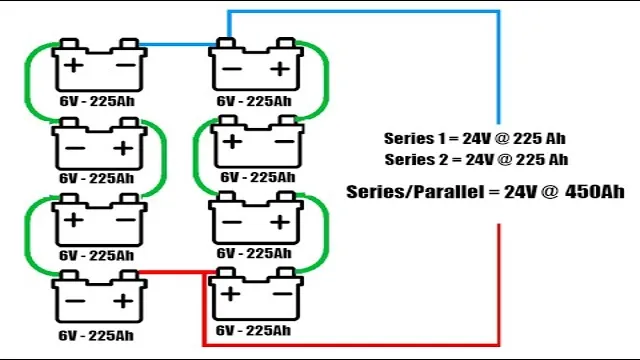

If you need to install freeze plugs in your car, it’s important to have the right tools and equipment on hand. Start by draining the coolant system, and then use a socket wrench to remove the old freeze plugs. You may need to tap the new freeze plugs into place with a hammer and a punch, being careful not to damage the surrounding metal.

Once all the plugs are installed, refill the coolant system with a mix of antifreeze and distilled water. It’s important to ensure that the coolant is topped off to the correct level, as a low coolant level can cause your engine to overheat. If you’re not experienced with car repairs, it may be best to bring your vehicle to a professional mechanic to ensure that everything is installed correctly.

By taking the time to properly install freeze plugs, you can help ensure that your car’s engine stays cool and runs smoothly for years to come.

Pour Coolant into Reservoir

If your vehicle’s coolant system is depleted or needs a refresh, it’s important to know how to refill it properly. Begin by checking your vehicle’s owner manual for specific directions on how to add coolant. Generally, the best way to refill the coolant system is by pouring coolant into the car’s reservoir.

Locate the reservoir, which is typically a translucent plastic tank and can be found under the hood next to the radiator. Once you have located the reservoir, remove the cap and slowly top off the coolant until it reaches the full line. It is important to wait for the engine to cool down before attempting to add coolant, so you don’t risk burning yourself.

Keep in mind that it’s crucial to use the recommended coolant specific to your vehicle to ensure optimal performance. Refilling your coolant system is a simple task, but it’s essential to complete correctly to avoid damage to your vehicle’s engine.

Check for Leaks

Checking for leaks in your car’s cooling system is essential to ensure that it is operating at peak performance. A leaking cooling system can cause your engine to overheat, which can lead to expensive repairs and potentially dangerous situations on the road. If you notice that your coolant levels are dropping rapidly or your engine is running hotter than usual, it’s time to check for leaks.

Start by inspecting all of the hoses and connections in the cooling system for cracks, splits, or signs of wear. Look for wet spots or puddles under your car, as this could be a sign of a leaking radiator or water pump. If you can’t find any visible leaks, it’s time to perform a pressure test to identify any hidden leaks.

Refilling your coolant system after fixing any leaks is crucial, as a low coolant level can cause your engine to overheat and potentially cause severe damage. Remember to check your coolant levels regularly and have your cooling system inspected regularly by a professional mechanic to prevent any issues before they become a bigger problem.

Conclusion

In conclusion, installing freeze plugs is no easy task, but with a little elbow grease and some know-how, it’s a job that any handy person can tackle. Whether you’re replacing a worn-out plug or upgrading your cooling system, the key is to take your time and do it right. Remember to clean the block thoroughly, use the proper tools and sealant, and double-check your work before filling with coolant.

And if all else fails, just remember the wise words of Shakespeare: “All’s well that ends well” – and that goes for freeze plugs too!”

FAQs

What are freeze plugs?

Freeze plugs, also known as expansion plugs, are metal plugs that are installed in the engine block to seal the casting holes left during the manufacturing process.

Why do freeze plugs fail?

Freeze plugs can fail due to corrosion, engine overheating, or improper installation.

How do I know if my freeze plugs need to be replaced?

Signs of a failed freeze plug include coolant leaks, engine overheating, and a loss of coolant.

How do I install freeze plugs?

To install freeze plugs, the old plug is removed and a new plug is tapped into place with a hammer and punch. It is important to ensure that the new plug is properly seated and sealed to prevent leaks.