Revive Your Engine: A Complete Guide on How to Fix Spun Bearing yourself

Have you ever heard a knocking sound coming from your engine? Maybe you noticed some loss of power or oil pressure? If so, it could be a sign that you have a spun bearing. This is a common problem that can happen to any engine, especially ones that are older. But, not to worry, in this complete guide we will cover everything you need to know about fixing a spun bearing.

Firstly, what is a spun bearing? A bearing is a component that sits between the connecting rod and the crankshaft. Its job is to ensure that the two parts move smoothly against each other without causing any friction. However, when a bearing spins, it means that it has become loose and is no longer able to keep the connecting rod in place.

This can lead to catastrophic engine failure, so it’s essential to address the issue as soon as possible. Next, how do you fix a spun bearing? There are a few options, depending on the severity of the issue. One solution is to replace the faulty bearing with a new one.

However, this can be costly and may require a lot of labor. Another option is to have your engine rebuilt, which involves replacing all of the bearings and other worn parts. This can be time-consuming and expensive, but it will ensure that your engine is in top condition.

Finally, it’s worth mentioning that prevention is always better than cure when it comes to engine maintenance. Regular oil changes and inspections can help prevent bearings from spinning in the first place. Also, avoiding engine modifications that can cause unnecessary stress to the engine, such as overloading or racing, can help prolong the life of your engine.

In conclusion, fixing a spun bearing can be a daunting task, but with the right approach, it’s certainly something that can be tackled. By understanding what a spun bearing is, how to fix it, and how to prevent it from happening again, you’ll be able to keep your engine running smoothly for years to come.

Identifying a Spun Bearing

When it comes to identifying a spun bearing, there are a few tell-tale signs that can clue you in. The most obvious symptom is a knocking noise that gets louder and more distinct as your car accelerates. This is a result of the bearing wearing down and no longer supporting the crankshaft as it should.

You may also notice a drop in oil pressure, as the bearing fails to maintain the proper clearance required for oil to flow through freely. If you suspect a spun bearing is the culprit, it’s important to address the issue quickly to prevent further damage to your engine. While it’s possible to fix a spun bearing yourself, it’s often a labor-intensive process that requires specialized tools and knowledge.

It’s recommended to consult with a professional mechanic to ensure the repair is done correctly. By catching and fixing a spun bearing early on, you can save yourself from costly repairs down the line and prevent serious engine damage.

Symptoms of a Spun Bearing

Identifying a Spun Bearing – Symptoms to Look Out For If you’re a car owner, at some point, you might have heard the term “spun bearing” being thrown around. But what exactly is a spun bearing, and how can you tell if you have one? A spun bearing typically refers to a damaged engine bearing that can cause significant problems if not dealt with promptly. One of the first symptoms you might notice is a loud knocking sound coming from your engine.

This noise can be quite severe and usually gets louder as you rev your engine. Another indicator of a spun bearing is a decrease in oil pressure, which can lead to engine failures. The best way to deal with a spun bearing is to take your car to a professional mechanic who can inspect and diagnose the issue.

In most cases, a spun bearing requires engine repair or replacement, which can be quite expensive. It’s always better to take preventative measures, such as regular oil changes and maintenance, to avoid this issue altogether.

Causes of Spun Bearings

Identifying a Spun Bearing is important to prevent major damage to your engine. Spun bearings occur when the bearing between the crankshaft and connecting rod lose their grip, resulting in metal-to-metal contact. This can create a knocking or hammering sound and cause vibrations in the car, which are the first signs of a potential issue.

There are several causes of spun bearings such as low oil pressure, high engine temperatures, and poor lubrication. Driving a car with a spun bearing can lead to catastrophic engine failure, so it’s essential to have it checked as soon as possible. Regular maintenance and oil changes can help prevent these types of issues and prolong the life of your vehicle’s engine.

If you hear any unusual noises or feel vibrations in your car, don’t hesitate to take it to a professional mechanic for inspection.

Fixing a Spun Bearing

If you’re experiencing a spun bearing in your engine, it’s important to address the problem immediately before it causes further damage. A spun bearing occurs when the bearing and the shaft no longer fit together properly, causing the bearing to spin within its housing. This can lead to a lack of lubrication, resulting in engine failure.

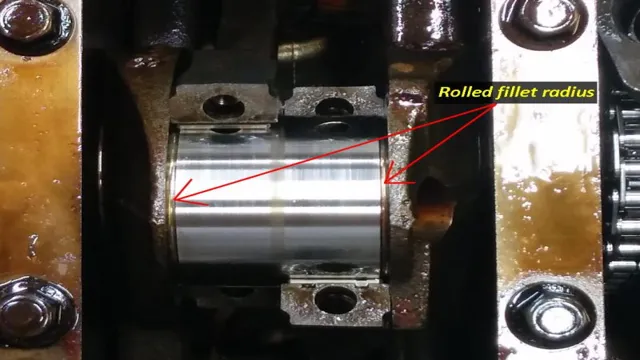

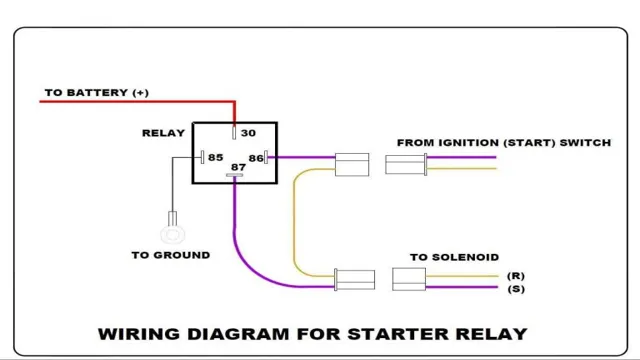

To fix the problem, you’ll need to remove the crankshaft and replace the bearing. It’s important to inspect the surrounding components for damage and debris before reassembling the engine. Additionally, it’s a good idea to check the oil pressure and flow to ensure proper lubrication.

Proper maintenance and regular oil changes can help prevent spun bearing and other engine issues in the future. So, don’t hesitate to seek professional help if you suspect a spun bearing in your engine. It’s better to address the problem early on and save yourself from a larger repair bill in the future.

Step-by-Step Instructions

If you’re dealing with a spun bearing, you’ll need to take action quickly before it causes severe damage to your engine. The first step is to diagnose the problem accurately. You’ll need to inspect the engine thoroughly and look for signs of damage.

If you find metal shavings, it’s a clear indication that the bearings are spun. In this case, you’ll need to replace the damaged bearings immediately. Before replacing the bearings, make sure to clean all the engine components properly.

Installing new bearings on a dirty surface can cause further damage. Additionally, it’s essential to use the right tools and equipment while working on the engine. Keep in mind that replacing a spun bearing is a complex process that requires patience, attention to detail, and the right skills.

If you’re not confident in your ability to fix the problem, it’s always best to seek professional help. Remember, neglecting a spun bearing can lead to significant engine failure, which can be expensive to repair. So, don’t take any chances and take action as soon as you notice the problem.

Tools Required

Fixing a spun bearing requires some specialized tools, but it’s not an impossible task. The most crucial tool is a micrometer to measure the bearings and determine the appropriate size for the replacement bearing. You’ll also need a bearing splitter and a puller to remove the old bearings.

A torque wrench and a socket set are essential for loosening bolts, and a pry bar or something similar can help with removal if necessary. A bearing press is also necessary to install the new bearings properly. It’s important to have the right tools and take your time when fixing a spun bearing to ensure that the repair is done correctly.

Remember, prevention is key to avoiding this problem in the future, so keep up with regular maintenance and keep an eye out for any signs of trouble. With the right tools and knowledge, fixing a spun bearing is definitely achievable.

Cost of Repair

If you have a spun bearing in your vehicle engine, you’re going to want to get it fixed as soon as possible. This type of damage can cause serious issues and lead to costly repairs down the line. The cost of fixing a spun bearing can vary depending on the extent of the damage and the make and model of your vehicle.

On average, you could be looking at a cost of anywhere from $500 to $1,500 for parts and labor. However, it’s important to note that this is just an estimated range and the actual cost could be higher or lower depending on various factors. It’s always a good idea to get an estimate from a reputable mechanic before committing to any repairs.

In some cases, it may be more cost-effective to replace the entire engine rather than repairing a spun bearing. At the end of the day, it’s important to address any engine issues promptly to avoid further damage and more expensive repairs in the future.

Preventing Spun Bearings

If you want to prevent spun bearings, it’s important to understand what causes them to happen in the first place. Spun bearings occur when the bearings lose their grip on the crankshaft, causing them to spin out of alignment. This can happen due to a lack of lubrication, high engine speeds, or excessive wear and tear on the bearings themselves.

To prevent this from happening, it’s important to use high-quality oil that can provide adequate lubrication to the bearings. You should also avoid revving your engine too high, driving aggressively, or towing heavy loads when your engine is already under stress. If you suspect that your engine may already be experiencing some wear and tear, it’s important to have it inspected and repaired as soon as possible to avoid more serious problems down the road.

By taking these simple preventative measures, you can help ensure that your engine stays running smoothly and avoid the need for costly repairs in the future.

Maintenance Tips

Spun bearings are one of the most common and detrimental issues that can occur in an engine, especially if it happens frequently. The cause of this problem is often due to insufficient lubrication that leads to overheating, metal-to-metal friction, and ultimately, the bearing shells will spin in their pockets. To prevent spun bearings, the most important thing to do is to perform regular and proper maintenance on your engine.

This includes changing your oil and filter at the recommended intervals, ensuring the oil level is always at the optimal range, and checking for any signs of metal flakes or debris in your oil that could indicate possible problems. Additionally, you should inspect the bearings for any signs of wear or damage, such as cracks or pitting, and replace them as needed. By taking these proactive steps, you can help prevent spun bearings and keep your engine running smoothly for longer.

So, always remember to keep up with your maintenance schedule, and don’t neglect any signs of engine problems to ensure your engine stays healthy.

Choosing the Right Vehicle Oil

Spun Bearings One of the most crucial aspects of maintaining the health of a vehicle engine would have to be using the right oil. The oil that is used in an engine is responsible for lubricating the various mechanical parts, including bearings and crankshafts. In order to prevent spun bearings, it is vital to choose an oil that is appropriate for the vehicle and its recommended specifications.

Spun bearings can occur when there is a lack of lubrication or when the oil being used does not meet the standards required by the engine manufacturer. When a bearing spins, it can damage the surrounding parts, including the crankshaft, which can result in a catastrophic loss of power or even complete engine failure. Therefore, it is essential to select an oil that meets the manufacturer’s specifications and to ensure regular oil changes.

By doing so, you can safeguard the health of your engine and prevent any major issues from occurring.

Conclusion

Fixing a spun bearing is like performing open-heart surgery on your engine. It requires precision, patience, and a willingness to dive deep into the inner workings of your car. But fear not, with the right tools, knowledge, and a steady hand, you can bring your engine back to life and have it purring like a kitten once again.

So roll up your sleeves, grab your wrenches, and get ready to give your car the TLC it deserves. And always remember, a properly maintained engine is the key to a long and happy road ahead.”

FAQs

What causes a spun bearing?

A spun bearing is typically caused by lack of lubrication or metal fatigue due to excessive stress.

How do I know if I have a spun bearing?

Signs of a spun bearing include a knocking noise from the engine, low oil pressure, and engine performance issues.

Can a spun bearing be repaired?

In most cases, a spun bearing cannot be repaired and must be replaced.

How much does it cost to fix a spun bearing?

The cost of repairing a spun bearing can vary depending on the make and model of the vehicle, but it typically ranges from $1,000 to $3,000.

How can I prevent a spun bearing from happening?

Regular maintenance, including oil changes and monitoring oil pressure, can help prevent a spun bearing from occurring. Additionally, avoiding excessive stress on the engine and using high-quality lubricants can also help prevent this issue.