How to Stop Engine from Turning When Removing Harmonic Balancer: Expert Tips

Removing a harmonic balancer from an engine can be a challenging task, especially when the engine continuously turns as you attempt to remove the balancer. This can make the task frustrating and time-consuming. However, with the right tools and techniques, you can effectively stop the engine from turning, making the removal of the harmonic balancer a much smoother process.

Understanding the Harmonic Balancer

Before we dive into the methods for stopping the engine from turning when removing the harmonic balancer, it’s important to understand the role of the harmonic balancer in an engine. The harmonic balancer, also known as the crankshaft damper, is a crucial component of an engine’s crankshaft assembly. It is designed to reduce torsional vibrations, which helps in improving the lifespan of the engine and reducing wear on critical components.

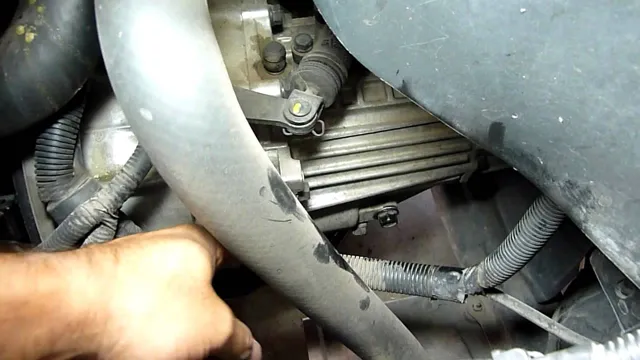

Credit: carfromjapan.com

Tools and Equipment

When it comes to stopping the engine from turning, having the right tools and equipment is essential. Here are some of the tools that you may need:

| Tools | Description |

|---|---|

| Socket Set | For removing bolts and fasteners |

| Harmonic Balancer Puller | For safely removing the harmonic balancer |

| Flywheel Locking Tool | To prevent the engine from turning |

| Wrench | For applying torque and loosening/tightening fasteners |

Methods for Stopping the Engine

There are several methods you can use to stop the engine from turning when removing the harmonic balancer. Here are some effective techniques:

Using A Flywheel Locking Tool

One of the most effective ways to stop the engine from turning is by using a flywheel locking tool. This tool is designed to hold the flywheel or flexplate in place, preventing the engine from rotating while you work on the harmonic balancer. Here’s how to use it:

- Locate the access hole in the bellhousing of the transmission.

- Rotate the engine until the flywheel’s teeth are visible through the hole.

- Insert the locking tool into the access hole and engage it with the flywheel teeth.

- Tighten the locking tool to secure the flywheel in place.

Using A Strap Wrench

Another method for stopping the engine from turning is by using a strap wrench. This tool grips the harmonic balancer, preventing it from rotating as you loosen the fasteners. Here’s how to use a strap wrench:

- Wrap the strap wrench around the harmonic balancer.

- Tighten the strap to securely grip the balancer.

- Use a breaker bar or ratchet to loosen the fasteners while holding the balancer in place with the strap wrench.

Using A Jamming Tool

A jamming tool can also be used to stop the engine from turning. This tool is inserted into the flywheel teeth or flexplate and prevents the engine from rotating. Here’s how to use a jamming tool:

- Locate the access hole in the bellhousing of the transmission.

- Insert the jamming tool into the access hole and engage it with the flywheel teeth or flexplate.

- Tighten the jamming tool to prevent the engine from turning.

Frequently Asked Questions On How To Stop Engine From Turning When Removing Harmonic Balancer: Expert Tips

How To Stop Engine From Turning When Removing Harmonic Balancer

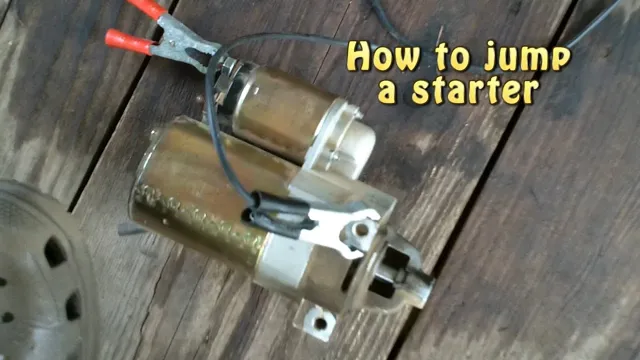

The harmonic balancer removal tool is designed to stop the engine from turning. It’s important to use this tool to avoid any damage to the engine when removing the harmonic balancer. You can also use a breaker bar and a chain wrapped around the balancer to stop the engine from turning.

It’s crucial to prevent the engine from turning to safely and effectively remove the harmonic balancer.

Conclusion

Removing a harmonic balancer can be a challenging task, especially if the engine keeps turning. However, with the right tools and techniques, you can effectively stop the engine from turning, making the removal process much smoother. Whether you opt for a flywheel locking tool, a strap wrench, or a jamming tool, it’s important to prioritize safety and precision when working on your engine’s harmonic balancer.