Revamp Your Engine with Ease: Step-by-Step Guide on Installing Freeze Plugs without Removing Your Engine

Installing freeze plugs is a vital part of maintaining your engine’s performance at an optimal level. As freeze plugs age, they can become weak and may fail, leading to costly engine damage. Typically, installing freeze plugs requires an engine removal, which can be expensive and time-consuming.

Fortunately, there is an alternative method that is much easier and more cost-effective. In this blog post, we’ll explore the process of installing freeze plugs without engine removal. We’ll walk you through the step-by-step process, including tools you’ll need, potential issues you may encounter, and tips for success.

By the end of this article, you’ll have the confidence and knowledge to install freeze plugs without the need for engine removal, saving you both time and money. Let’s get started!

Overview of Freeze Plugs and their Installation

Freeze plugs, also known as expansion plugs or core plugs, are essential components in the engine block of a vehicle. They are designed to protect the engine from cracking or damaging due to freezing temperatures. Installing freeze plugs is a relatively simple process that can be done without removing the engine.

First, the old freeze plug must be removed using a screwdriver, pliers, or a special tool. Then, the new freeze plug can be installed using a rubber mallet and sealant. It is important to make sure the new freeze plug is flush with the engine block to ensure proper sealing.

If not installed correctly, freeze plugs can cause oil leaks or even engine failure. Proper installation of freeze plugs is crucial to ensuring the longevity and efficiency of an engine. By following these simple steps and taking precautions, you can install freeze plugs without removing your engine and keep your vehicle running smoothly during cold temperatures.

What are Freeze Plugs?

Freeze Plugs Freeze plugs, otherwise known as expansion plugs or core plugs, are small metal plugs that are installed into the engine block or cylinder head of an internal combustion engine. Their purpose is to help protect the engine from damage caused by freezing fluids. They also help to balance the pressure in the engine block by creating an escape route for coolant or oil in the event of overheating.

Installing freeze plugs is a relatively simple process that can be done by a competent mechanic. The first step is to drain the coolant from the engine, then remove any debris from around the freeze plugs. The old plugs can be removed using a screwdriver, pliers, or a specialized tool.

The new plugs can then be hammered into place using a rubber mallet or a piece of wood, making sure they are flush with the surface of the engine block. Once all the freeze plugs are in place, the engine can be refilled with coolant and started up. Overall, freeze plugs are a small but important component of any internal combustion engine and should be maintained regularly to ensure they are working correctly.

Why Would You Need to Replace Them?

Freeze plugs, also known as expansion plugs, are small metal disks that are installed in the engine block to seal the coolant passages. They are designed to pop out if the coolant in the engine freezes and expands, preventing the block from cracking. However, freeze plugs can also corrode or deteriorate over time, causing leaks and engine damage.

Other reasons to replace freeze plugs include engine rebuilds, restoration projects, or upgrades. Installing new freeze plugs involves removing the old ones, cleaning the engine block, and pressing the new plugs into place. While it may seem like a small and simple task, replacing freeze plugs can save you from costly engine repairs in the long run.

So, if you notice any signs of leaks or corroded freeze plugs, don’t hesitate to have them replaced.

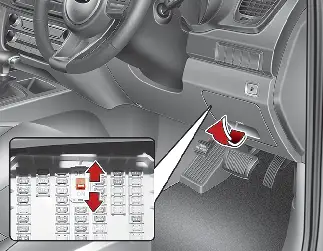

Tools Required for Installation without Engine Removal

If you are planning to install freeze plugs without removing the engine, there are a few tools that you will need. These include a hammer, freeze plug installation tool, and a sealant. Freeze plugs are an important component of the engine, as they help to keep the coolant flowing properly through the block.

When a freeze plug fails, coolant can leak out of the system, causing overheating and potential damage to the engine. Installing a new freeze plug can be a bit tricky, as you need to ensure that it is properly seated in the block. However, with the right tools and a bit of patience, it can be done without too much trouble.

So, if you need to replace a freeze plug in your engine, be sure to have these tools on hand and take your time to do the job right.

Step-by-Step Guide to Installing Freeze Plugs without Removing the Engine

Wondering how to install freeze plugs without removing the engine? Don’t worry, it’s possible and can save you a lot of time and money! Here’s a step-by-step guide to get you started. First, gather the necessary tools such as a freeze plug installation kit, pliers, and a flashlight. Next, locate the freeze plugs that need replacing by checking under the vehicle or referring to the repair manual.

Clean the area around the freeze plug to prevent debris from getting inside the engine. Next, use the pliers to remove the old freeze plug and insert the new one. Use the installation kit to secure the new freeze plug in place and ensure a strong seal.

Repeat these steps for each freeze plug that needs to be replaced. Always make sure to double-check your work and test the engine’s performance afterward. With a little patience and know-how, you can successfully install freeze plugs without removing the engine!

Step 1: Draining the Engine Cooling System

In order to install freeze plugs without having to remove the engine, there are a few steps you need to follow. The first step in the process is to drain the engine cooling system. This is important because any coolant left in the engine can cause potential damage or corrosion to the new freeze plugs you will be installing.

To drain the system, locate the drain plug on the radiator and place a catch pan underneath it. Loosen the drain plug and allow the coolant to completely drain out. Once all of the coolant has been drained, you can move on to the next step.

By properly draining the engine cooling system, you are ensuring that your new freeze plugs will be installed in a clean and safe environment, allowing them to perform at their best without any risk of damage.

Step 2: Removing the Old Freeze Plugs

When it comes to installing freeze plugs without removing the engine, removing the old freeze plugs is the next step after identifying the damaged ones. This process can be a bit tricky depending on the location of the plug and the amount of access available to it. The first step is to ensure that the engine is cool enough to work on, then locate the plug using a flashlight or a mirror if necessary.

You can use a flat head screwdriver or a punch tool to create a hole in the middle of the freeze plug without causing any damage to the engine block. Once you have created a small hole, you can use a pry bar to lever the plug out of the engine. Be careful not to damage the surrounding area while doing so, as this could cause bigger problems down the line.

With the old freeze plug removed, you can move on to the next steps of cleaning and installing the new ones. Overall, removing the old freeze plugs is an essential step in the process of installing new ones without removing the engine, and with a little care and attention, it can be accomplished with ease.

Step 3: Preparing the New Freeze Plugs for Installation

To properly install freeze plugs without removing the engine, the new plugs must be prepared ahead of time, to ensure a tight fit. The first step in this process is to match the new plugs to the old ones, by comparing size and shape. Once they have been matched, any sharp edges on the new plugs can be sanded down using a small piece of sandpaper, making them easier to insert into the freeze plug ports.

Next, a thin layer of sealant can be applied to the outer edges of the new plugs, to help prevent any potential leaks. Once all of the new plugs have been prepared in this manner, they can be carefully inserted into the freeze plug ports, one at a time. With the new plugs in place, the engine should be checked for leaks and other potential issues, to ensure that the installation process was successful.

By following these steps, you can replace your engine’s freeze plugs without removing the engine itself, making the process much easier and more manageable.

Step 4: Installing the New Freeze Plugs

Installing freeze plugs without removing the engine can be a daunting task, but with these step-by-step instructions, you can do it like a pro. Now that you have prepared the engine block and cleaned the freeze plug holes, it’s time to install the new freeze plugs. Start by placing the new freeze plug into the hole and tapping it gently with a hammer until it is flush with the engine block.

It’s important to make sure the freeze plug is level, or else it may leak coolant. Next, use a freeze plug installation tool to expand the new plug until it is snugly seated in the hole. Repeat this process for all of the remaining freeze plugs.

Once all of the new plugs are installed, check them to ensure they are level and fully seated. With these new freeze plugs, your engine will be ready to go and leak-free!

Step 5: Refilling and Testing the Engine Cooling System

Step-by-Step Guide to Installing Freeze Plugs without Removing the Engine When it comes to replacing freeze plugs, many people think it means pulling the engine out of the vehicle. But with the proper tools and some patience, it is possible to install freeze plugs without removing the engine. Once you have removed the old freeze plugs, cleaned the area around them, and installed the new ones, the next step is to refill and test the engine cooling system.

First, make sure the engine is cool before you begin refilling the cooling system. Then, remove the radiator cap and add a 50/50 mixture of coolant and water until the radiator is full. You may also need to add coolant to the overflow reservoir at this time.

Next, start the engine and allow it to run until it reaches its normal operating temperature. This will help ensure that the cooling system is functioning properly. Check the temperature gauge and the coolant level during this process.

Once the engine has reached its normal operating temperature, turn off the engine and allow it to cool for a few minutes. Then, use a radiator pressure tester to check for any leaks in the cooling system. If you find a leak, you may need to tighten the connections or replace any damaged parts.

Overall, installing freeze plugs without removing the engine is possible with the right tools and patience. By following these step-by-step instructions, you can ensure that your vehicle’s cooling system is functioning properly and avoid the hassle of pulling the engine out of the vehicle.

Tips and Tricks for a Successful Installation

If you’re looking to install freeze plugs without removing your engine, there are a few tips and tricks to keep in mind. First, it’s important to note that this process can be challenging and may require some specialized tools. However, with the right approach, it is possible to get the job done.

One tip is to make sure the engine is completely cool before you start working. This will help you avoid burns and other injuries, and will also allow you to work more efficiently. Another tip is to use a pry bar or similar tool to carefully remove the old freeze plugs without damaging the surrounding area.

Finally, be sure to use a high-quality sealant or epoxy to ensure the new freeze plugs are securely in place. With a careful and methodical approach, you can successfully install new freeze plugs without removing your engine and get your vehicle back on the road in no time.

Using Sealant for Added Protection

If you’re planning to install sealant for added protection, here are some tips and tricks for a successful installation. First and foremost, it’s important to choose the right type of sealant for your specific needs. Whether you want to seal your windows, doors, roof, or other areas of your home, there are different sealants available for each application.

Before you start, make sure to read the manufacturer’s instructions carefully and follow them precisely. Prep work is also crucial when it comes to sealant installation. The surface needs to be clean and dry before applying the sealant, as any dirt or moisture can compromise its effectiveness.

Lastly, don’t skimp on the amount of sealant you use. It’s always better to apply too much than too little, as you want to make sure every nook and cranny is covered. With these tips in mind, you can rest assured that your sealant installation will be a success and provide the added protection you desire.

Sanding Freeze Plug Surface before Installation

Sanding Freeze Plug Surface before Installation: Tips and Tricks for a Successful Installation When it comes to installing freeze plugs, it’s important to prepare the surface properly to ensure a successful installation. One of the most effective ways to do this is by sanding the surface of the freeze plug and the surrounding area before installation. This will provide a rough surface that allows the sealant to adhere better, which will prevent leaks and ensure a tight fit.

To sand the surface, you’ll need a fine-grit sandpaper that’s suitable for use on metal surfaces. Begin by cleaning the surface with a degreaser to remove any dirt or debris. Then, use the sandpaper to lightly sand the surface in a circular motion until it feels slightly rough to the touch.

Be sure to sand the entire surface evenly to avoid any ridges or high spots that could cause the plug to sit unevenly. Once you’ve sanded the surface, wipe it clean with a clean cloth to remove any dust or debris. Then, apply a thin layer of sealant to the surface before inserting the freeze plug.

This will help to further seal the plug and prevent leaks. In conclusion, sanding the surface of freeze plugs before installation is a simple yet effective way to ensure a successful installation. By following these tips and tricks, you can be confident that your freeze plugs will fit tightly and prevent leaks.

So, the next time you’re installing freeze plugs, be sure to give sanding the surface a try!

Avoiding Common Mistakes during the Installation Process

When it comes to installing new equipment or appliances, mistakes can happen, and they can be costly. One of the common mistakes during the installation process is not reading the manual carefully. Many people tend to skip the instructions and try to install the equipment on their own, which often results in improper installation and damage.

Always read the manual carefully and follow the instructions step-by-step. It’s also important to have all the necessary tools and equipment beforehand. Do not assume you already have everything you need at home.

Double-check the requirements before starting the installation process. Another common mistake is not shutting off the power before starting the installation. Electrical appliances and equipment can be dangerous, and it’s crucial to turn off the power before handling them.

Lastly, make sure to test the equipment after installation thoroughly. It’s easy to assume that everything is working fine without checking it, but it can cause trouble in the long run. By following these tips and tricks, you can avoid common mistakes during the installation process and ensure a successful installation.

Conclusion

In conclusion, installing freeze plugs without removing your engine may seem like a daunting task, but with the right tools and techniques, it can be done. Just like solving a puzzle, this process requires patience, skill, and a bit of creativity. So, grab your freeze plugs, put on your thinking cap, and get ready to give your engine the TLC it deserves.

Who said you need to take the whole engine apart? Not you, not anymore. Happy plug-popping, folks!”

FAQs

What are freeze plugs and why do they need to be replaced?

Freeze plugs are small metal plugs located on the engine block that can be pushed out in extreme temperatures or when coolant is not properly maintained. They need to be replaced if they become damaged or corroded to prevent coolant leaks and engine damage.

Can freeze plugs be replaced without removing the engine?

Yes, freeze plugs can be replaced without removing the engine but it can be a difficult and time-consuming task. A special tool called a freeze plug installer is needed to properly install new freeze plugs.

What is the process for replacing freeze plugs without removing the engine?

The process involves draining the coolant, removing any obstructions such as the alternator or motor mounts, removing the old freeze plugs and installing new ones with a freeze plug installer tool. Care must be taken to not damage the engine block during the installation process.

Should I replace all the freeze plugs at once?

It is recommended to replace all the freeze plugs at once since they are all the same age and may be corroding at the same rate. This prevents the need for future replacements and ensures the engine is properly protected from coolant leaks.