Master the Art of Flipping a Trailer Axle: Step-by-Step Guide for Beginners

Flipping a trailer axle might seem like a daunting task, but with the right tools and know-how, it can be done easily and efficiently. Whether you are looking to increase ground clearance or want to change the trailer’s height, flipping the axle is a straightforward solution that can save you time and money. In this blog post, we will go over the step-by-step process of how to flip a trailer axle and the tools you will need for the job.

So, buckle up and let’s get started on this axle-flipping adventure!

Tools Required

If you’re looking to raise your trailer for better ground clearance or to fit larger wheels, flipping the axle can be a great solution. However, it’s not a job to be taken lightly and requires a few specialized tools to do it properly. Firstly, you’ll need to jack up the trailer so that the wheels are off the ground.

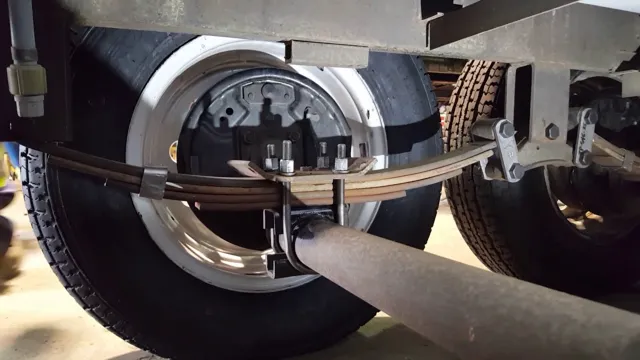

A hydraulic bottle jack is ideal for this job, along with jack stands that can support the weight of the trailer. You’ll also need a socket set with various sizes of sockets, a torque wrench, and a pry bar to remove the U-bolts and leaf springs that hold the axle in place. A welder will come in handy to weld new spring perches onto the axle after it’s been flipped, but if you don’t have access to a welder, you can always buy a new axle with the perches already in place.

With these tools in hand and the right safety precautions taken, you’ll be able to flip your trailer axle in no time and have a more efficient and effective trailer for your needs.

Wrenches, Jack stands, Pry bar, Nut splitter

When it comes to basic car maintenance, having the right tools can make all the difference. In particular, there are a few essentials that every car owner should have on hand. These include wrenches, jack stands, pry bars, and nut splitters.

Wrenches are a versatile tool that can be used to tighten or loosen bolts and nuts of varying sizes. A good set of wrenches will include both standard and metric sizes, as well as different types such as open-end and box-end wrenches. Jack stands are an important safety measure whenever working underneath a vehicle.

These sturdy supports are used to hold up the car while you work on it, preventing it from falling and causing serious injury. Pry bars are another versatile tool that can be used to remove stubborn components such as bearings, gears, and seals. These tools come in different shapes and sizes and are typically made of hardened steel, making them durable and long-lasting.

Finally, nut splitters are a specialized tool used to remove rusted or damaged nuts that can’t be removed with a wrench or socket. These tools work by cutting into the nut and allowing you to twist it off. Overall, having these basic tools on hand can help you tackle many common maintenance tasks and avoid costly trips to the mechanic.

So, next time you’re performing basic maintenance on your car, make sure you have these essential tools at the ready!

Steps to Flip the Axle

Flipping the axle of a trailer might seem like a daunting task, but with the right tools and a bit of know-how, it can be done easily. Firstly, measure the distance between the axle and the frame to check if flipping the axle is even possible. Then, jack up the trailer and support it with jack stands.

Next, detach the wheels, brakes, and shocks of the axle you want to flip. Remove the nuts, bolts, and u-bolts that connect the spring assembly to the axle. Once you have disconnected everything, simply flip the axle over and reattach the spring assembly in the new position.

After that, reattach the wheels, brakes, and shocks, and your axle is good to go! Remember to always use proper safety precautions when working on your trailer, and if you’re unsure of anything, seek advice from a professional. With these steps, you can easily flip your trailer’s axle and enjoy a smoother ride.

1. Lift the trailer using jack stands.

If you’re looking to flip your trailer’s axle, you’ll need to first lift the trailer using jack stands. This is an essential step to ensure the safety of both you and your trailer. Once you’ve got the trailer lifted, take a good look at the current axle and determine the specific type of axle you’ll need for your swap.

There are various types available, including square, round, and drop axles. Consider the weight capacity of your trailer as well as the ride height of the new axle. Once you’ve selected the appropriate replacement axle, you’ll need to remove the old one and attach the new one.

This is a job best left to someone with mechanical experience and expertise, but if you’re up for the challenge, be sure to use sturdy equipment and take safety precautions throughout the process. With the right tools and techniques, flipping your axle can improve the overall performance and functionality of your trailer.

2. Remove wheel and brake components.

If you’re looking to flip the axle on your trailer, it’s important to first remove the wheel and brake components. This is a necessary step in the process, as it will allow you to access the axle and begin the necessary work to flip it. To do this, start by loosening the lug nuts on your wheel and lifting the trailer with a jack.

Once you’ve removed the wheel, detach the brake components, including the brake drum, backing plate, and hub. It’s important to be careful during this step to avoid damaging any of these components, as they’ll need to be reattached later. Once you’ve removed these parts, you should be able to access the axle and proceed with the flipping process.

Make sure to keep all of the parts organized and safe, so you can easily reassemble everything when you’re done. Flipping an axle can be a daunting task, especially if you’re not familiar with the process. However, with the right tools and a bit of know-how, it’s definitely achievable.

By taking the time to remove the wheel and brake components before flipping the axle, you’ll be able to ensure that the whole process goes smoothly and efficiently. Remember, it’s always better to take your time and do things carefully, rather than rush through them and risk damaging your equipment. With a bit of patience and attention to detail, you’ll be able to successfully flip your trailer axle and get back to using it in no time.

3. Remove the old spring and attaching hardware.

When flipping an axle on your trailer, the first step is to remove the old spring and any attaching hardware. This is important because it allows you to inspect the old components for wear and damage, as well as properly align the new spring and hardware during installation. Removing the old spring can be a bit tricky, so it’s important to follow the correct procedure to avoid any injuries.

Start by loosening the bolts that secure the spring hanger to the trailer frame, then use a jack to lift the trailer off the axle, providing enough clearance to remove the spring and hardware. Use caution during this process, and be sure to stabilize the trailer before removing the old components. With the old spring and hardware removed, you’re ready to move on to the next step in the process of flipping your trailer’s axle.

4. Flip the axle over.

Flipping the axle over is a simple and common process that can help you improve the load-carrying capacity of your vehicle. To flip the axle over, you need to begin by lifting the vehicle using a jack and removing the wheels. With the wheels off, you need to place the jack stand beneath the frame of the vehicle to provide stability and prevent any unwanted movements.

Next, you should locate the leaf springs and remove the U-bolts that attach it to the axle. Once the leaf springs have been released, you can flip the axle over, position it correctly, and reattach the leaf springs using new U-bolts. With the leaf springs attached, you can reinstall the wheels, lower the vehicle, and admire your increased load-carrying capacity.

Flip the axle over is a quick process that can make a big difference when it comes to hauling heavy loads, so try it out today!

5. Install the new attaching hardware.

When it comes to flipping an axle, it’s essential to install new attaching hardware to ensure the axle is securely mounted. This process involves removing the old hardware and replacing it with new bolts, nuts, and other necessary components. The attaching hardware may vary depending on the type and size of the axle, so it’s crucial to choose the correct hardware for the job.

A loose or improperly attached axle can result in serious accidents, so this step is critical to ensure your safety on the road. By taking the time to install the new attaching hardware correctly, you’ll be able to enjoy a smoother ride with better control and stability. So, make sure to invest in high-quality hardware and double-check everything to avoid any issues down the road.

Ultimately, taking the time to complete this step correctly will give you peace of mind and help you have a successful axle flipping experience.

6. Reinstall the spring.

When it comes to flipping an axle, it’s essential to follow the proper steps to ensure the process goes smoothly and safely. One of the key steps in this process is reinstalling the spring. To do this, start by placing the spring on the table with the larger end facing up.

Next, slide the spring seat onto the top of the spring, followed by the spring perch. Make sure to align the holes in these pieces with the holes in the spring. Then, slide the bolt through all three pieces and tighten it firmly.

Finally, reattach the brake assembly and the wheels, and you’re finished. By following these steps, you can flip your axle with ease and confidence, ensuring your vehicle is ready for whatever challenges come your way.

7. Reinstall the brake components.

“Flip the Axle” When it comes to flipping the axle on a trailer, it’s important to make sure that you follow each step carefully to ensure that the process is completed safely and efficiently. One of the final steps in the process is to reinstall the brake components. This involves putting the brake shoes back in place and reinstalling the hardware that secures them.

Once this is completed, you will need to reinstall the brake drums, making sure they are properly aligned and torqued to specification. It’s important to note that there may be other components that need to be reinstalled as well, depending on the type of brake system your trailer has. This is not a step to rush through or skip over, as properly functioning brakes are crucial for safe towing.

By taking the time to reinstall the brake components correctly, you can rest assured that your trailer will be safe and reliable for all your towing needs.

8. Repeat on the other side.

Flipping the axle is a crucial step in maintaining your car’s suspension system. It is not a difficult process, but it requires a bit of basic knowledge and experience. To start with, lift your car off the ground using a jack and support it safely on axle stands.

Grab a wrench and loosen up the lug nuts before you remove the wheel and tire. Once you take off the wheel, you will have access to the axle. Use a pry bar to push the axle out of the hub and flip it over.

Make sure you don’t damage the brake cable or the brake caliper. Once flipped, slide the axle back into the hub and use the pry bar to push it in firmly. Tighten up the lug nuts and lower your car back on the ground.

Finally, repeat the same steps on the other side of your car. You are all set! By flipping the axle, you extend the lifespan of your tires and ensure a smooth ride. So, don’t hesitate to do it yourself and save some money on maintenance costs!

Safety Precautions

When it comes to flipping a trailer axle, safety should be your top priority. This is a task that can cause serious injury or damage to your vehicle if done improperly. Before starting, ensure the trailer is on level ground and securely chocked.

Make sure to wear safety glasses and gloves to protect your hands and eyes. It is also recommended to have a helper nearby to assist you with the process. When lifting the trailer, use a hydraulic jack and heavy-duty jack stands to prevent it from falling.

Always follow the manufacturer’s instructions and ensure you have the proper tools, such as a socket set and torque wrench. Once the axle is flipped, double-check that everything is correctly tightened and secured before taking your trailer out on the road. Remember, taking the time to follow these safety precautions can save you from an unfortunate accident.

Use safety glasses, do not work under unsupported weight, secure the trailer from rolling.

When it comes to working with trailers, safety should always be your top priority. Simple precautions like wearing safety glasses can go a long way in preventing accidents. It’s also important to never work underneath an unsupported weight.

Make sure that your trailer is secure and that you have proper equipment to lift heavy objects. And, of course, always be mindful of preventing roll-aways. Secure your trailer and never park it on an incline without proper safety measures.

These may seem like simple steps, but they could mean the difference between a job well done and a life-threatening situation. Remember, safety first!

Conclusion

In conclusion, flipping a trailer axle can seem like a daunting task, but with the right tools and knowledge, it can be done easily and efficiently. It’s the trailer equivalent to a gymnastics floor routine- it requires a bit of agility, strength, and precision. By following these simple steps and paying attention to details, you’ll be well on your way to a smoother and safer ride.

So flip that axle like a pro, and relish in the satisfaction of a job well done – your trailer and your towing experience will thank you!”

FAQs

What is a trailer axle?

A trailer axle is a component that attaches the wheels to the trailer chassis and helps with load-bearing.

Why flip a trailer axle?

Flipping a trailer axle can help increase ground clearance, improve weight distribution, and adjust trailer height.

How do I know if my trailer axle needs to be flipped?

You can check if your trailer sits too low, scrapes over bumps, or has uneven tire wear. These signs may indicate that your axle needs to be flipped.

Can I flip any trailer axle?

No, not all trailer axles can be flipped. It depends on the design and shape of the axle. Check with your trailer manufacturer or mechanic to determine if your axle is compatible with flipping.

How do I flip a trailer axle?

To flip a trailer axle, you will need to remove the wheels, detach the axle from the chassis, flip it over, and reattach it. Make sure to follow proper safety precautions and consider hiring a professional for help.