DIY Guide: How to Direct Wire a Fuel Pump – Step by Step Tutorial

Are you considering direct wiring your fuel pump? It may seem like a daunting task, but with the right knowledge and tools, it can be a relatively simple process. Direct wiring your fuel pump can provide several benefits, including improved fuel efficiency, increased horsepower, and a longer lifespan for your vehicle’s engine. By bypassing the factory wiring and connecting your pump directly to the battery, you can ensure a constant and reliable source of power.

But before you get started, it’s important to understand the best practices and precautions to take when working with electrical systems. In this blog, we’ll cover everything you need to know about direct wiring a fuel pump, from the benefits to the step-by-step process and important safety tips. So, grab your toolbox and let’s get started!

Understanding Your Fuel Pump Wiring

If you’re experiencing issues with your fuel pump, direct wiring can be a helpful solution. Direct wiring your fuel pump may seem complicated, but in reality, it’s a simple process. First, locate the wiring harness for your fuel pump and the power source wires.

Next, using wire cutters, separate the power wires from the harness. Then, strip the ends of the wires and twist them together before connecting them to the power source. It’s important to note that when direct wiring your fuel pump, you’ll want to ensure that you have the correct power source and that all wiring is secure to avoid any potential hazards.

By following these steps, you can direct wire your fuel pump and get back on the road with confidence. So, next time you’re experiencing issues with your fuel pump, consider trying direct wiring as a solution.

Identifying the Positive and Negative Wires

When it comes to your fuel pump wiring, it’s important to understand how to identify the positive and negative wires. The positive wire, also known as the hot wire, is typically colored red and provides power to the fuel pump. On the other hand, the negative wire, or ground wire, is usually colored black and acts as the connection to the vehicle’s electrical system.

It’s essential to correctly identify these wires to ensure proper fuel pump function and prevent any electrical issues. If you’re unsure how to identify them, consult your vehicle’s wiring diagram or seek assistance from a professional mechanic. Remember, a properly functioning fuel pump is key to ensuring your vehicle runs smoothly and efficiently.

Locating a Reliable Power Source

When it comes to locating a reliable power source for your vehicle’s fuel pump, understanding your fuel pump wiring is crucial. The fuel pump wiring is responsible for supplying power to the fuel pump, which allows it to draw fuel from the tank and deliver it to the engine. Before attempting to diagnose any issues, it’s important to understand the wiring diagram and identify any potential faults.

One common issue is a faulty fuel pump relay, which can cause the engine to stall or prevent it from starting altogether. To avoid any potential hazards, it’s recommended to consult with a professional mechanic who can assist with any wiring or electrical issues. Overall, understanding your fuel pump wiring is essential for ensuring a dependable and efficient power source for your vehicle’s engine.

Wiring the Fuel Pump

If you’re having issues with your fuel pump and suspect that the electrical wiring is to blame, you may need to direct wire it. Wiring your fuel pump directly involves bypassing the engine wiring harness and connecting the pump to a power source via a wire of its own. Before you attempt this, ensure that you have thorough knowledge of your vehicle’s electrical system.

Begin by locating the fuel pump relay and using a circuit tester to identify the power coming into and out of the relay. Next, connect a wire from the power source directly to the fuel pump, and another wire from the ground on the pump to a suitable ground source in the vehicle. Once that’s done, test the pump to see if it’s working effectively.

Direct wiring your fuel pump may seem like a daunting task, but it’s a skill that’s worth having in your automotive repair arsenal. Remember to always prioritize safety when it comes to electrical work and to thoroughly research the details before beginning the task.

Preparing the Wiring Connections

Wiring the fuel pump is an essential step when preparing the wiring connections of your vehicle. But before we delve into the wiring process, it’s vital to ensure that the fuel pump you’ve chosen is compatible with your car’s electrical system. The correct fuel pump must be picked to avoid electrical malfunctions or even complete failure.

Once that’s out of the way, the next step is to ensure that you have all the necessary equipment ready, including the splicing tools and connectors. After that, you can commence with wiring the fuel pump by following the manufacturer’s instructions and connecting the wires from the car’s electrical system to the fuel pump. Bear in mind that this process does require a certain level of technical understanding.

If you’re not familiar with vehicle wiring, it may be best to seek the help of a professional. Proper installation of the fuel pump wiring is critical for the efficient operation of the pump, which is why it should never be rushed or taken lightly.

Connecting the Fuel Pump to a Relay

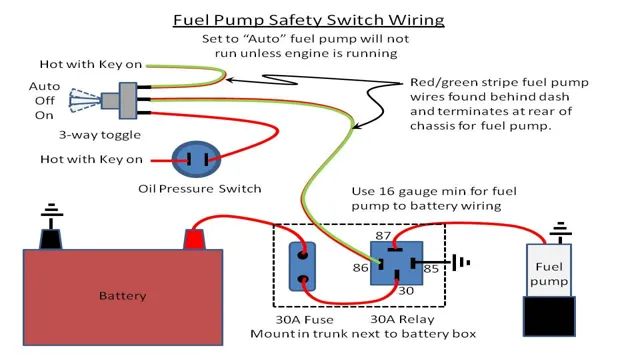

Connecting the fuel pump to a relay is an essential step in wiring a fuel pump. The relay acts as a switch that ensures the fuel pump receives the power it needs to function correctly. The first step is to gather the necessary supplies, including a relay, wiring, and crimp connectors.

The next step is to identify the fuel pump wires and connect them to the corresponding wires on the relay. It’s important to ensure that the wiring is secure and free from any damage or fraying. Once the wiring is connected, it’s time to test the fuel pump to ensure that everything is functioning correctly.

Wiring a fuel pump can seem intimidating at first, but with the right tools and a little know-how, you can ensure that your fuel pump is working correctly and keeping your vehicle running smoothly.

Connecting the Relay to a Switch

When it comes to wiring a fuel pump, one essential step is connecting the relay to a switch. Before you start, make sure you have the necessary tools and materials, including a relay, switch, wire connectors, and a fuse holder. First, connect the relay to the battery’s positive terminal and then ground the negative terminal.

The relay should have two wires for the pump and two for the switch. Then, connect one wire of the switch to the ignition switch’s accessory wire, and the other wire to a 12-volt power source. It’s important to ensure that the power source is switched, so it only has power when the ignition is on.

Once you have connected the wires, test the circuit to make sure everything works as expected. By connecting the relay to a switch, you can control the fuel pump and ensure it only runs when you need it to. Overall, this is an easy task that doesn’t require any special skills or knowledge, but it’s important to take the time to do it correctly to avoid any potential issues or accidents.

Testing the Fuel Pump Wiring

If you suspect that your fuel pump isn’t working properly, you may want to direct wire it to test the wiring. This process will bypass the car’s electrical system and send power directly to the fuel pump. Before you start, you’ll need to locate the fuel pump and remove it from the tank.

Once you have access to the pump, you can test the wiring by connecting the battery directly to the pump’s positive and negative terminals. If the pump turns on, then you know that the wiring is functioning correctly. If it doesn’t, you may need to replace the wiring or the pump entirely.

Remember to be cautious throughout the process, and always work with gloves and protective gear to avoid any potential hazards. Direct wiring your fuel pump can be a quick and easy way to determine if there is an issue with your car’s electrical system that’s causing problems with your fuel pump. So, next time you experience a problem with your fuel pump, give direct wiring a try!

Checking for Proper Connection

When testing the fuel pump wiring, it is important to check for proper connection to ensure optimal safety and functionality of your vehicle. A loose or faulty connection can cause your fuel system to fail, leading to unexpected breakdowns and dangerous situations. To test your fuel pump wiring, start by locating the fuel pump relay and fuse.

Check for any signs of damage or wear, such as frayed wires or corrosion. Next, use a multimeter to test the voltage of your fuel pump wiring. Make sure to follow the manufacturer’s instructions carefully, and record the values you get for future reference.

If you suspect a problem with your fuel pump wiring, it’s best to have it inspected by a professional mechanic to avoid any potential risks. By taking the time to check for proper connection, you can ensure a smooth and safe ride every time you hit the road.

Testing for Power and Ground

Testing for power and ground is crucial when troubleshooting fuel pump wiring. A lack of power can indicate a blown fuse, a faulty relay, or a broken wire, while a lack of ground can suggest a corroded or loose connection or a damaged wiring harness. To test for power, you can use a multimeter to measure the voltage at the fuel pump fuse or relay.

If the reading is zero, you can check for continuity on the wires leading to the fuse or relay or use a test light to check for power at the fuel pump connector. To test for ground, you can use the ohmmeter function of your multimeter to measure the resistance between the fuel pump connector and a known ground point, such as the battery negative terminal or the chassis. If the reading is infinite or too high, you can try cleaning the ground connection or running a temporary ground wire to see if it solves the problem.

Remember to always disconnect the battery before testing any wiring to prevent electrical damage or injury. By testing for power and ground, you can determine whether the fuel pump wiring is faulty and take appropriate action to repair or replace it.

Precautions When Direct Wiring a Fuel Pump

Direct wiring a fuel pump can be a risky endeavor that requires careful attention to detail. Before attempting to connect the fuel pump directly to a power source, it is important to take some precautions to ensure that the process goes smoothly. One of the most important things to do is to make sure that the wiring is done correctly, using the proper gauge of wire, and that there is no exposed or frayed wiring.

Additionally, it is crucial to make sure that the power source is adequate to handle the needs of the fuel pump and that the connection is made to the correct terminals. Another critical safety measure that should not be skipped is the installation of a fuse or circuit breaker to prevent any accidental fires or electrical damage in case of a short circuit. With these precautions in place, direct wiring your fuel pump can be a straightforward process.

However, if you’re unsure of your abilities or if you’re not familiar with working with electrical wiring, it’s best to seek professional advice to ensure a safe and effective installation.

Conclusion

In conclusion, directing wiring a fuel pump is an exciting feat that requires brains, brawn, and lots of wires. It’s a delicate balancing act that requires precision and attention to detail, just like a high-wire circus act. So, get ready to channel your inner electrical engineer, pull out your favorite pliers, and have a blast unleashing your inner wiring maestro.

And remember, this job isn’t for the faint of heart – it’s a thrilling adventure for those who love to live on the edge, or at least on the electrical edge.”

FAQs

What is direct wiring a fuel pump?

Direct wiring a fuel pump means connecting it to the power source without using a relay or an external wiring harness. This is usually done to improve the fuel pump’s performance.

Is it safe to direct wire a fuel pump?

Direct wiring a fuel pump is not recommended as it can cause a fire hazard if not done properly. It is important to follow the manufacturer’s instructions and use the correct wiring size and connectors.

How do I know if my fuel pump needs direct wiring?

Most modern vehicles are designed to operate with a fuel pump relay, so direct wiring is not usually necessary. However, if you have a high-performance fuel pump or are experiencing fuel delivery issues, direct wiring may be necessary. Consult with a mechanic or the fuel pump manufacturer for guidance.

Can direct wiring a fuel pump cause damage to my vehicle?

Direct wiring a fuel pump can cause damage to your vehicle if not done properly. It can overload the electrical system, causing damage to the fuel pump, wiring, or other components. It can also cause a fire if the wiring is not properly insulated or secured. It’s important to follow the manufacturer’s instructions and have a professional mechanic perform the installation if you’re unsure.