7.3 Powerstroke Low Fuel Pressure Symptoms: Identifying Potential Issues

The 7.3 Powerstroke engine has gained a reputation for its durability and reliability, making it a popular choice among truck enthusiasts and diesel engine fans. However, like any mechanical system, it is not immune to potential issues. One common problem that can occur in the 7.3 Powerstroke engine is low fuel pressure.

Low fuel pressure can lead to a range of performance problems and can negatively impact the engine’s overall efficiency. Identifying the symptoms of low fuel pressure is crucial for early detection and prompt resolution, preventing further damage and costly repairs.

In this blog post, we will explore the various symptoms that may indicate low fuel pressure in a 7.3 Powerstroke engine. From rough idling and sluggish acceleration to engine misfires and fuel system-related issues, we will delve into the telltale signs that may point to a fuel pressure problem.

By understanding these symptoms, you’ll be better equipped to diagnose potential issues and take appropriate action to rectify them. Whether it involves simple maintenance tasks, fuel system component replacements, or seeking professional assistance, our aim is to provide you with valuable insights and solutions to keep your 7.3 Powerstroke engine running smoothly.

What is the importance of priming the fuel system before starting the engine?

Priming the fuel system before starting the engine holds tremendous significance in ensuring a smooth and safe operation of the vehicle. By priming the fuel system, we prevent potential damage to the fuel injectors, which could occur if the engine is started without this essential step.

Priming the fuel system involves a straightforward process that entails turning the key to the ‘On’ position for a specified duration, typically 30 seconds. This action initiates the flow of fuel through the system and helps build the necessary pressure for optimal fuel delivery to the engine.

The reason why priming the fuel system is vital is because, without it, attempting to start the engine can lead to serious consequences. Starting the engine without priming can cause damage to the fuel injectors, which play a critical role in delivering fuel to the combustion chamber. The injectors rely on proper pressure and fuel flow to function effectively. Failing to prime the fuel system before starting the engine can result in insufficient fuel supply, leading to misfires, poor acceleration, reduced fuel efficiency, and even potential engine damage.

To ensure a thorough priming process, it is recommended to repeat the key-turning procedure a minimum of three times. This repetition allows for the proper pressurization of the fuel system, ensuring that an adequate amount of fuel is delivered to the injectors for the engine to start smoothly.

Thus, priming the fuel system before starting the engine is of utmost importance as it safeguards the fuel injectors from potential damage and guarantees an optimal fuel supply to support the engine’s performance. By following this essential step, we can maximize engine efficiency, prevent costly repairs, and enable a reliable and safe operation of the vehicle.

7.3 Powerstroke Low Fuel Pressure Symptoms

Low fuel pressure in a 7.3 Powerstroke engine can manifest through several symptoms that indicate potential issues within the fuel system. Here are seven common symptoms to watch out for:

Rough Idling

If you notice your engine idling roughly or inconsistently, it could be a sign of low fuel pressure. The engine may struggle to maintain a steady RPM, causing vibrations or a shaky idle.

Sluggish Acceleration

Insufficient fuel pressure can result in reduced power and sluggish acceleration. Your vehicle may feel noticeably slower when accelerating, making it challenging to reach desired speeds efficiently.

Engine Misfires

Low fuel pressure can lead to incomplete combustion in the cylinders, resulting in engine misfires. You may experience hesitation, stumbling, or a loss of power during acceleration.

Difficulty Starting

A weak fuel pressure can make it difficult for the engine to start, particularly when the vehicle has been sitting for an extended period. You may experience prolonged cranking or multiple attempts before the engine fires up.

Fuel System Related Issues

Low fuel pressure can cause issues with other components in the fuel system. These may include fuel pump failures, clogged fuel filters, or a decreased lifespan of fuel injectors due to inadequate fuel supply.

Poor Fuel Economy

If your fuel mileage suddenly drops without any noticeable changes in driving habits, it could indicate low fuel pressure. Insufficient fuel delivery can lead to inefficient combustion, resulting in decreased fuel economy.

Stalling or Engine Cutouts

In extreme cases of low fuel pressure, the engine may stall or experience sudden cutouts while driving. This is a significant safety concern, as it can occur unexpectedly and result in loss of control.

Reason For Low Fuel Pressure On 7.3 Powerstroke : Cold Weather

Cold weather can be a contributing factor to low fuel pressure in a 7.3 Powerstroke engine. Here’s how cold weather can affect the fuel system and lead to reduced fuel pressure:

Fuel Viscosity

In colder temperatures, diesel fuel tends to thicken and become more viscous. The increased viscosity can make it difficult for the fuel to flow smoothly through the fuel lines, filters, and injectors. As a result, the fuel pressure may drop due to restricted fuel flow.

Fuel Gelling

When temperatures drop significantly, diesel fuel can form gel-like substances, known as fuel gelling. These gels can clog fuel filters and restrict fuel flow, causing a decrease in fuel pressure. Fuel gelling is more common in low-quality or untreated diesel fuel.

Cold Start Issues

Starting a diesel engine in cold weather requires a higher pressure fuel supply to facilitate combustion. If the fuel pressure is already low due to cold-induced issues, it can lead to difficulties in starting the engine or prolonged cranking before it fires up.

Fuel System Moisture

Cold weather can create condensation within the fuel system. Moisture accumulation in the fuel can result in the formation of ice crystals, which can obstruct fuel flow and cause a drop in fuel pressure.

To mitigate low fuel pressure issues in cold weather, here are some preventive measures:

- Use winter-grade diesel fuel with appropriate additives to prevent fuel gelling and maintain fuel flow.

- Ensure the fuel system components, such as fuel lines, filters, and injectors, are in good condition and free from leaks or blockages.

- Install fuel heaters or fuel line insulation to maintain optimal fuel temperature.

- Park the vehicle in a sheltered, heated area or use block heaters to warm the engine before starting in cold weather.

What To Do When You Detect 7.3 Powerstroke Low Fuel Pressure?

When you detect low fuel pressure in your 7.3 Powerstroke engine, it’s crucial to take prompt action to prevent further damage and restore proper fuel delivery. Here are the steps you should follow:

1. Confirm the Issue

Use a fuel pressure gauge to verify that the fuel pressure is indeed low. This will help ensure that the symptoms you are experiencing are indeed related to fuel pressure and not another underlying problem.

2. Check Fuel Filters

Inspect the fuel filters for any signs of clogging or contamination. Replace them if necessary, as clogged filters can restrict fuel flow and cause low pressure. It’s recommended to use high-quality, OEM-approved fuel filters for optimal performance.

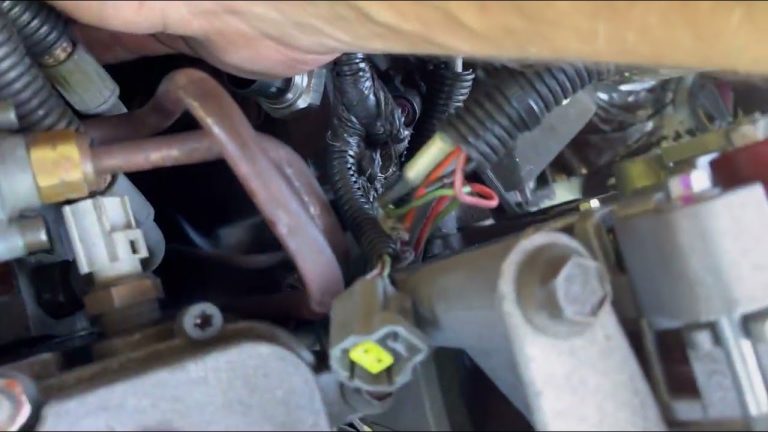

3. Check Fuel Lines and Connections

Inspect the fuel lines and connections for any signs of leaks, cracks, or loose fittings. Tighten loose connections and replace damaged or deteriorated fuel lines as needed. Ensure that the fuel lines are not kinked or blocked, impeding proper fuel flow.

4. Fuel Pressure Regulator Inspection

Check the fuel pressure regulator, which helps maintain optimal fuel pressure. Ensure it is functioning correctly and not stuck or malfunctioning. Replace the regulator if necessary.

5. Fuel Pump Examination

The fuel pump is responsible for delivering fuel to the engine. Check its condition and functionality. If the fuel pump is failing or weak, it may result in low fuel pressure. Consider replacing the fuel pump if needed.

6. Address Fuel System Contamination

If fuel contamination is suspected, such as water or debris in the fuel, it’s important to address it. Drain and replace the fuel if necessary, and consider using fuel additives to clean the fuel system.

7. Consult a Professional

If you’re unsure about the diagnosis or lack the necessary tools and expertise, it’s advisable to consult a qualified mechanic or diesel specialist. They can perform a comprehensive inspection, conduct diagnostic tests, and provide professional guidance on resolving the low fuel pressure issue.

Remember, safety precautions should be observed when working with fuel. Avoid smoking or using open flames near the fuel system, and take necessary precautions to prevent fuel spills or leaks.

By addressing low fuel pressure promptly, you can ensure optimal engine performance, prevent damage to fuel system components, and maintain the reliability of your 7.3 Powerstroke engine.

Is Fixing 7.3 Powerstroke Low Fuel Pressure Expensive?

The cost of fixing low fuel pressure in a 7.3 Powerstroke engine can vary depending on several factors, such as the underlying cause of the issue and the extent of the required repairs. Here are some factors that can influence the cost:

1. Cause of Low Fuel Pressure

The cost will depend on identifying the specific cause of the low fuel pressure. It could be related to issues such as clogged fuel filters, a faulty fuel pump, a malfunctioning fuel pressure regulator, or fuel system contamination. The cost will vary based on the necessary repairs or component replacements.

2. DIY vs. Professional Repairs

The cost can differ depending on whether you choose to perform the repairs yourself or seek professional assistance. DIY repairs may be more affordable if you have the necessary skills and tools. However, professional repairs ensure expert diagnosis, accurate repairs, and can help avoid costly mistakes.

3. Replacement Parts

If any components need to be replaced, such as fuel filters, fuel pump, or fuel pressure regulator, the cost will depend on the brand, quality, and availability of the parts. OEM (Original Equipment Manufacturer) parts may be more expensive than aftermarket options, but they often offer better reliability and performance.

4. Labor Costs

If you opt for professional repairs, labor costs will be a factor. Labor rates can vary depending on the location and the specific repair shop. Complex repairs may require more time and expertise, leading to higher labor costs.

While fixing low fuel pressure may incur costs, it is important to address the issue promptly to prevent further damage to the fuel system and maintain the performance and longevity of your 7.3 Powerstroke engine.

How Often Should You Inspect 7.3 Powerstroke Low Fuel Pressure?

Regular inspection of the fuel pressure in a 7.3 Powerstroke engine is important to ensure optimal performance and catch any issues early on. However, the specific frequency of inspection may vary depending on factors such as the age of the vehicle, its usage patterns, and the overall condition of the fuel system. Here are some general guidelines to consider:

Manufacturer’s Recommendations

It is always a good idea to consult the vehicle’s owner manual or contact the manufacturer to determine their recommended maintenance schedule. They may provide specific guidelines on when to inspect the fuel pressure and related components.

Routine Maintenance Intervals

As a general rule, it is advisable to have the fuel system inspected during routine maintenance intervals. This typically includes services like oil changes, air filter replacements, and other scheduled maintenance tasks. Consider having the fuel pressure checked at least once a year or every 10,000 to 15,000 miles, whichever comes first.

Symptom-Based Inspections

If you experience any symptoms of low fuel pressure, such as rough idling, sluggish acceleration, or engine misfires, it is crucial to inspect the fuel pressure promptly. These symptoms may indicate an underlying issue that needs to be addressed to prevent further damage.

After Fuel System Repairs

If you have recently performed repairs or replacements on the fuel system, it is a good practice to inspect the fuel pressure as part of the post-repair checks. This helps ensure that the repairs were successful and that the fuel pressure is within the specified range.

FAQ:

Q1: What are the symptoms of low fuel pressure in a 7.3 Powerstroke engine?

A: Low fuel pressure in a 7.3 Powerstroke engine can manifest through several symptoms, including rough idling, sluggish acceleration, engine misfires, difficulty starting, fuel system-related issues, poor fuel economy, and stalling or engine cutouts.

Q2: How can I confirm if my 7.3 Powerstroke engine has low fuel pressure?

A: To confirm low fuel pressure, you can use a fuel pressure gauge to measure the pressure in the fuel system. This will help you verify if the pressure is below the recommended range and if it is indeed the cause of the symptoms you are experiencing.

Q3: What can cause low fuel pressure in a 7.3 Powerstroke engine?

A: Several factors can contribute to low fuel pressure, including clogged fuel filters, a faulty fuel pump, a malfunctioning fuel pressure regulator, fuel system contamination, or issues related to cold weather affecting fuel viscosity and flow.

Q4: Can I drive my 7.3 Powerstroke with low fuel pressure?

A: It is generally not recommended to drive a vehicle with low fuel pressure. Low fuel pressure can lead to engine performance issues, potential damage to fuel system components, and even engine stalling. It is best to address the issue promptly to avoid further damage and ensure safe operation.

Q5: Can I fix low fuel pressure in my 7.3 Powerstroke engine myself?

A: Depending on your skill level and experience with automotive repairs, you may be able to address some low fuel pressure issues yourself. However, it is advisable to consult a qualified mechanic or diesel specialist, especially for complex repairs or if you are unsure about the diagnosis. They can provide accurate guidance and ensure the problem is resolved correctly.

Q6: How much does it cost to fix low fuel pressure in a 7.3 Powerstroke engine?

A: The cost of fixing low fuel pressure can vary depending on the specific cause of the issue, the required repairs or replacements, and labor costs. It is recommended to consult a mechanic or diesel specialist for a detailed estimate based on your specific situation.

Q7: How often should I inspect the fuel pressure in my 7.3 Powerstroke engine?

A: It is recommended to have the fuel pressure inspected during routine maintenance intervals, which is typically once a year or every 10,000 to 15,000 miles. However, if you experience symptoms of low fuel pressure, it is important to inspect it promptly to avoid further damage.

Q8: What is the common issue with water in the fuel system in diesel-powered vehicles?

A: One common issue frequently encountered in diesel-powered vehicles is the accumulation of water in the fuel system. There are several factors that contribute to the presence of water in the fuel tank. For instance, water can accumulate due to condensation forming within the tank, improper storage or handling procedures, or even as a result of a defective tank. Regardless of the specific cause, the entry of moisture into the fuel system is a common concern among diesel vehicle owners.

Q9: How can the HFCM and manifold be cleaned to remove rust and sediment?

A: To clean the HFCM and manifold and remove rust and sediment, follow these steps:

- Inspect the interior of the manifold to assess the amount of sediment accumulated. Rust and sediment can pose problems if they come into contact with the WIF sensor.

- Begin by removing all the sediment from the HFCM and manifold. Use a rag or small brush to wipe away any large portions of sediment.

- Proceed to spray the HFCM and manifold with a brake parts cleaner. This cleaner is effective in removing rust and other contaminants.

- As you wipe the HFCM and manifold, observe the rag to gauge the amount of sediment that was present. This will give you an idea of the thoroughness of the cleaning process.

- Hold the HFCM and manifold over a catch container and continue spraying them with the brake parts cleaner. Be sure to drain and clean until all metal surfaces are free of debris and rust.

- After a comprehensive cleaning, you should notice a notable improvement in the condition of the manifold and HFCM.

Q10: How can water become present in the fuel tank?

A: Water can find its way into a vehicle’s fuel tank through various means. One frequent occurrence in diesel-powered vehicles is the accumulation of water within the fuel system. There are several ways in which water can infiltrate the tank. For instance, condensation may form within the fuel tank over time due to changes in temperature and humidity. Improper storage or mishandling of the vehicle, such as exposing it to rain or other sources of water, can also introduce moisture into the tank. Additionally, a defective tank or a faulty fuel system component may allow water to enter. In any case, the presence of moisture in the fuel tank is nearly inevitable due to these contributing factors.